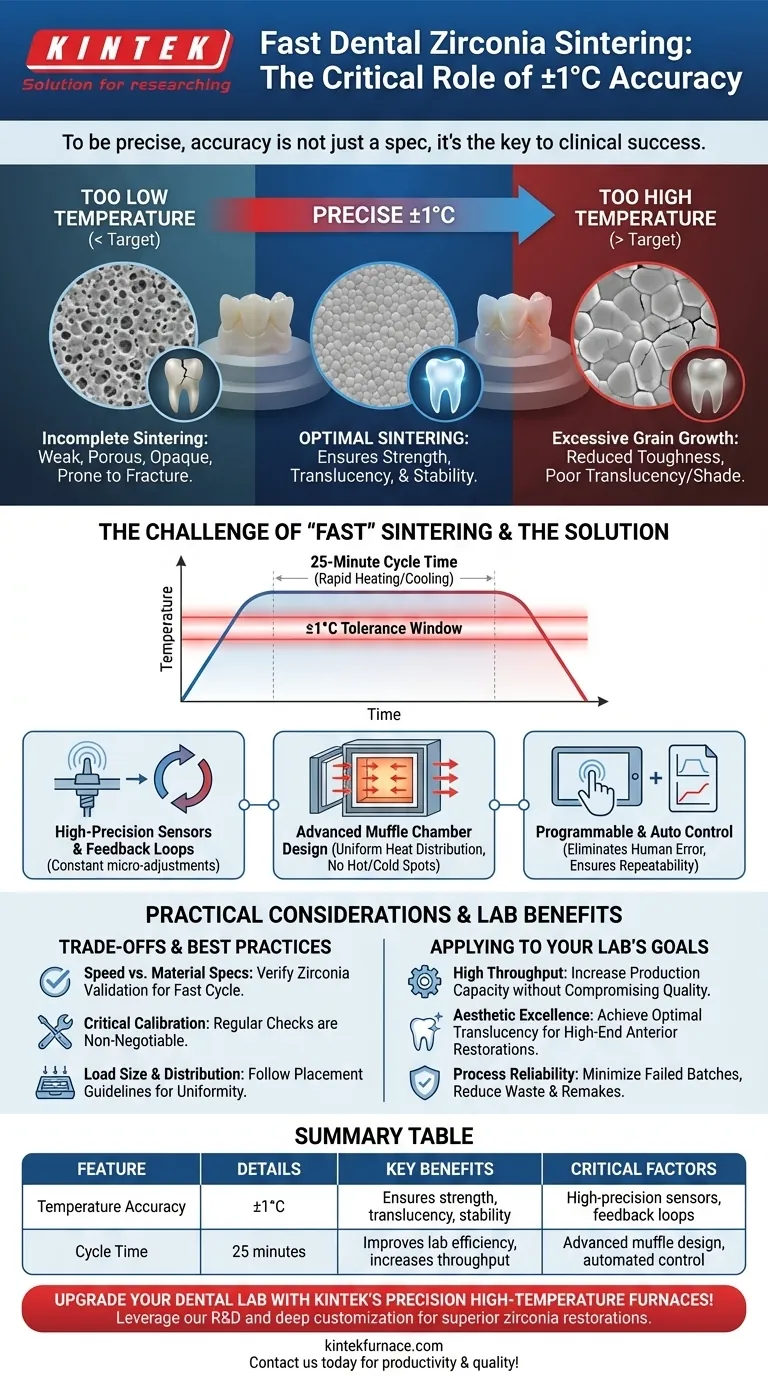

To be precise, the temperature accuracy of a Fast Dental Zirconia Sintering Furnace is ±1°C. This level of precision is not just a technical specification; it is the critical factor that ensures the final dental restoration has the required strength, translucency, and dimensional stability for clinical success.

The core value of a fast sintering furnace is its ability to combine high-speed processing with exceptional temperature accuracy. While the 25-minute cycle time improves lab efficiency, the ±1°C precision is what guarantees the quality and reliability of the final zirconia restoration.

Why ±1°C Accuracy is the Clinical Standard

A dental lab's output is judged by the final restoration. The sintering process is arguably the most critical step in determining the material properties of zirconia, and temperature is the most critical variable in that process.

The Direct Impact on Zirconia's Properties

Even a small deviation from the target sintering temperature can have significant consequences. This is because temperature directly governs the densification and grain growth of the zirconia crystals.

Too low a temperature results in incomplete sintering, leading to a porous, weak, and opaque restoration that is prone to fracture.

Too high a temperature can cause excessive grain growth, which paradoxically can also reduce fracture toughness and negatively impact the material's translucency and shade.

The Challenge of "Fast" Sintering

Achieving uniform and stable temperature is significantly more difficult in a rapid heating and cooling cycle. The furnace must be able to inject and then remove a massive amount of thermal energy very quickly without overshooting the target temperature or creating hot and cold spots within the chamber.

Maintaining a ±1°C tolerance under these dynamic conditions is a hallmark of a well-engineered furnace.

How Modern Furnaces Achieve This Precision

This level of control is not accidental. It is the result of a combination of advanced hardware and intelligent software working in concert to maintain a stable thermal environment.

High-Precision Sensors and Feedback Loops

The core of the system is a high-precision temperature sensor (thermocouple) paired with an automatic feedback system. The controller constantly monitors the internal temperature and makes instantaneous micro-adjustments to the heating elements to keep fluctuations within the ±1°C range.

Advanced Muffle Chamber Design

The physical design of the heating chamber is crucial. Modern furnaces often use a double-shell structure with superior insulation. This design ensures uniform heat distribution, preventing thermal gradients that could cause inconsistent sintering across a single restoration or between multiple units in the same batch.

Programmable and Automated Control

Features like touch-screen controls and the ability to store multiple programmed sintering curves provide consistency. This automation removes the variable of human error and ensures that every cycle for a specific material is executed with identical, repeatable precision.

Understanding the Practical Trade-offs

While highly accurate, no technology is without its operational considerations. Understanding these ensures you achieve the best possible results from the equipment.

Speed vs. Material Specifications

The main benefit is a 25-minute cycle, but not all zirconia materials are validated for such rapid sintering. Always verify the zirconia manufacturer’s instructions. Using the wrong cycle can compromise the restoration, regardless of furnace accuracy.

The Critical Role of Calibration

A furnace's stated accuracy of ±1°C is only valid if the unit is properly calibrated. Regular calibration checks are non-negotiable to compensate for thermocouple drift over time and ensure the furnace is performing to specification.

Load Size and Heat Distribution

While the furnace is designed for uniform heating, the way you load restorations into the chamber matters. An overly dense or improperly arranged load can create minor variations in temperature. Following best practices for placement ensures every unit receives the intended thermal exposure.

Applying This to Your Laboratory's Goals

Choosing and using equipment effectively comes down to aligning its capabilities with your primary objectives.

- If your primary focus is high throughput: The combination of a 25-minute cycle and ±1°C accuracy allows you to drastically increase production capacity without compromising clinical quality.

- If your primary focus is aesthetic excellence: The precise temperature control enables you to perfectly match the sintering parameters required to achieve optimal translucency for high-end anterior restorations.

- If your primary focus is process reliability: The furnace's automated controls and stable thermal environment minimize failed batches, reducing material waste and the need for costly remakes.

Ultimately, this level of temperature accuracy empowers your lab to produce consistently reliable and aesthetic zirconia restorations with maximum efficiency.

Summary Table:

| Feature | Details |

|---|---|

| Temperature Accuracy | ±1°C |

| Cycle Time | 25 minutes |

| Key Benefits | Ensures strength, translucency, and dimensional stability of zirconia restorations |

| Critical Factors | High-precision sensors, advanced muffle design, programmable controls, and regular calibration |

Upgrade your dental lab with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met, delivering reliable, efficient sintering for superior zirconia restorations. Contact us today to discuss how our furnaces can enhance your lab's productivity and quality!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations