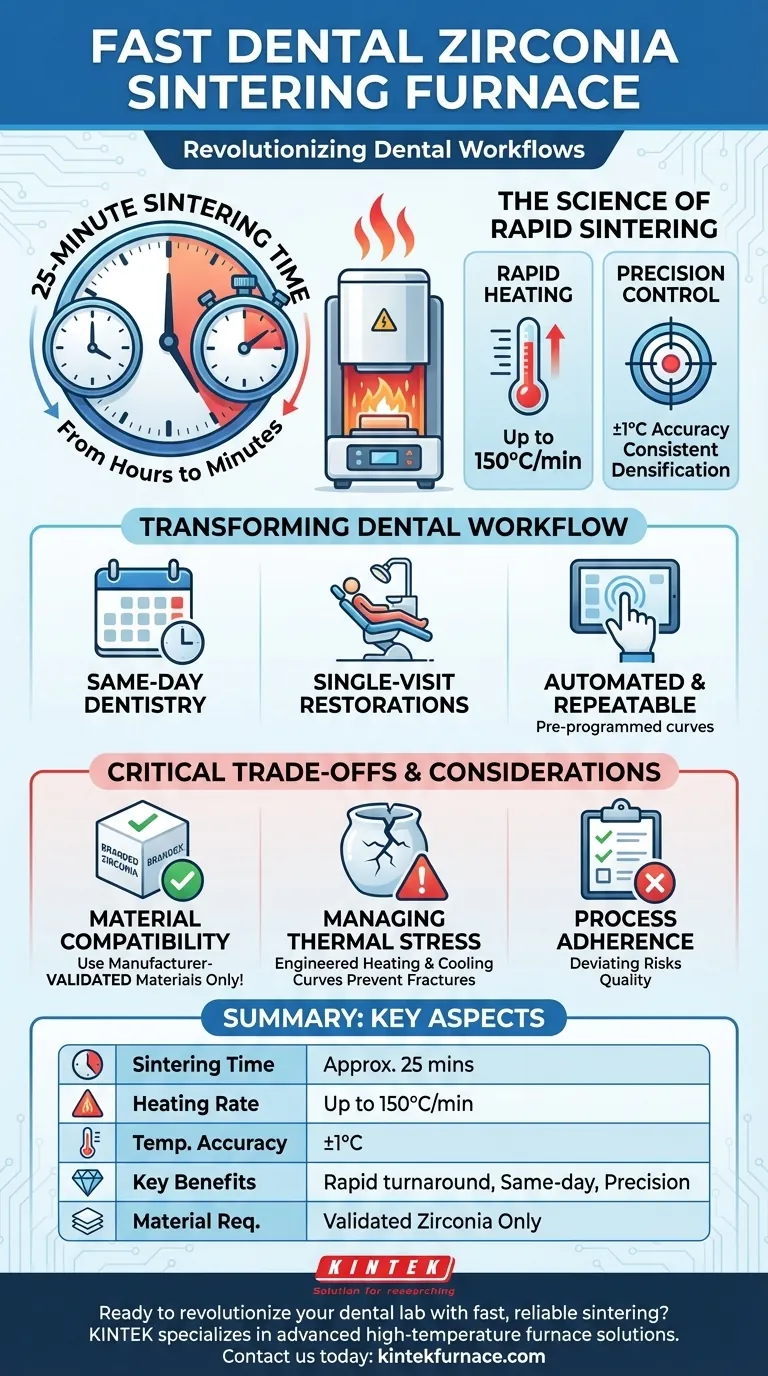

For a Fast dental Zirconia Sintering Furnace, the entire sintering process is completed in approximately 25 minutes. This rapid cycle time is a significant departure from traditional multi-hour sintering processes, fundamentally changing the workflow for producing zirconia dental restorations.

The core advantage is not just the speed itself, but how it's achieved: an extremely rapid heating rate combined with precise temperature control. This pairing allows dental professionals to significantly shorten restoration turnaround times without compromising the final material quality.

The Science of Rapid Sintering

To appreciate the impact of a 25-minute cycle, it's important to understand the underlying technology that makes it possible. The process is a careful balance of speed and precision.

What is Zirconia Sintering?

Sintering is a high-temperature process that transforms a porous, chalk-like zirconia milling block into a dense, strong, and translucent final restoration. Heat causes the individual ceramic particles to bond and fuse together, a process known as densification, which gives the material its final strength and aesthetic properties.

The Key to Speed: Rapid Heating

The defining feature of this furnace is its ability to heat up at an exceptional rate, reaching up to 150°C per minute. This rapid thermal ramp-up is the primary reason the entire cycle can be condensed into just 25 minutes.

Precision is Non-Negotiable

Speed without control is ineffective. This furnace maintains a strict temperature accuracy of ±1°C. Such precision ensures that the zirconia reaches the exact target temperature needed for full densification, guaranteeing consistent and reliable results for every restoration.

How This Technology Transforms the Dental Workflow

A 25-minute sintering cycle is more than an incremental improvement; it represents a fundamental shift in how dental restorations are delivered.

From Hours to Minutes

Traditional sintering furnaces can take several hours to complete a cycle. This often means restorations milled one day cannot be delivered until the next. The fast furnace eliminates this overnight delay entirely.

Enabling Same-Day Dentistry

This speed is a key enabler for single-visit restorations. A crown or bridge can be designed, milled, sintered, and seated in the patient's mouth within a single appointment, dramatically improving the patient experience and clinic efficiency.

Automation and Repeatability

Modern fast furnaces integrate features like a touch screen with pre-programmed sintering curves and automated tray handling. This simplifies the workflow, reduces the chance of user error, and ensures every restoration is processed according to ideal, validated parameters.

Understanding the Trade-offs

While the speed is a major benefit, it's critical to understand the associated considerations to ensure optimal outcomes.

Material Compatibility

Not all zirconia materials are designed for ultra-fast sintering. It is essential to use only zirconia discs and blocks that have been specifically validated by the manufacturer for rapid sintering cycles. Using an incompatible material can result in incomplete sintering, reduced strength, or poor aesthetics.

Managing Thermal Stress

Rapid heating and cooling can introduce stress into ceramic materials. These furnaces use carefully engineered, pre-programmed heating and cooling curves to manage this thermal shock and prevent fractures or warping, preserving the integrity of the restoration.

Process Adherence

The 25-minute cycle is a highly optimized process. Deviating from the manufacturer's recommended settings or using unvalidated materials negates the benefits and introduces significant risk to the final quality of the dental restoration.

How to Apply This to Your Practice

Your specific goals will determine how you leverage this technology.

- If your primary focus is maximizing clinic efficiency: The 25-minute cycle is a game-changer, enabling true same-day dentistry and dramatically increasing patient throughput.

- If your primary focus is material integrity and quality: You must pair the furnace with zirconia materials specifically validated for ultra-fast sintering protocols to guarantee optimal strength and translucency.

- If your primary focus is research and development: The rapid heating and precise control offer a unique tool for studying the effects of accelerated densification on various ceramic compositions.

Ultimately, this technology empowers dental professionals to deliver high-quality restorations with unprecedented speed.

Summary Table:

| Aspect | Details |

|---|---|

| Sintering Time | Approximately 25 minutes for full cycle |

| Heating Rate | Up to 150°C per minute |

| Temperature Accuracy | ±1°C |

| Key Benefits | Rapid turnaround, same-day dentistry, precise control |

| Material Requirements | Use only manufacturer-validated zirconia for optimal results |

Ready to revolutionize your dental lab with fast, reliable sintering? KINTEK specializes in advanced high-temperature furnace solutions, including our customizable Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we tailor our products to meet your unique needs for efficiency and quality. Contact us today to discuss how our furnaces can enhance your workflow and deliver superior dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations