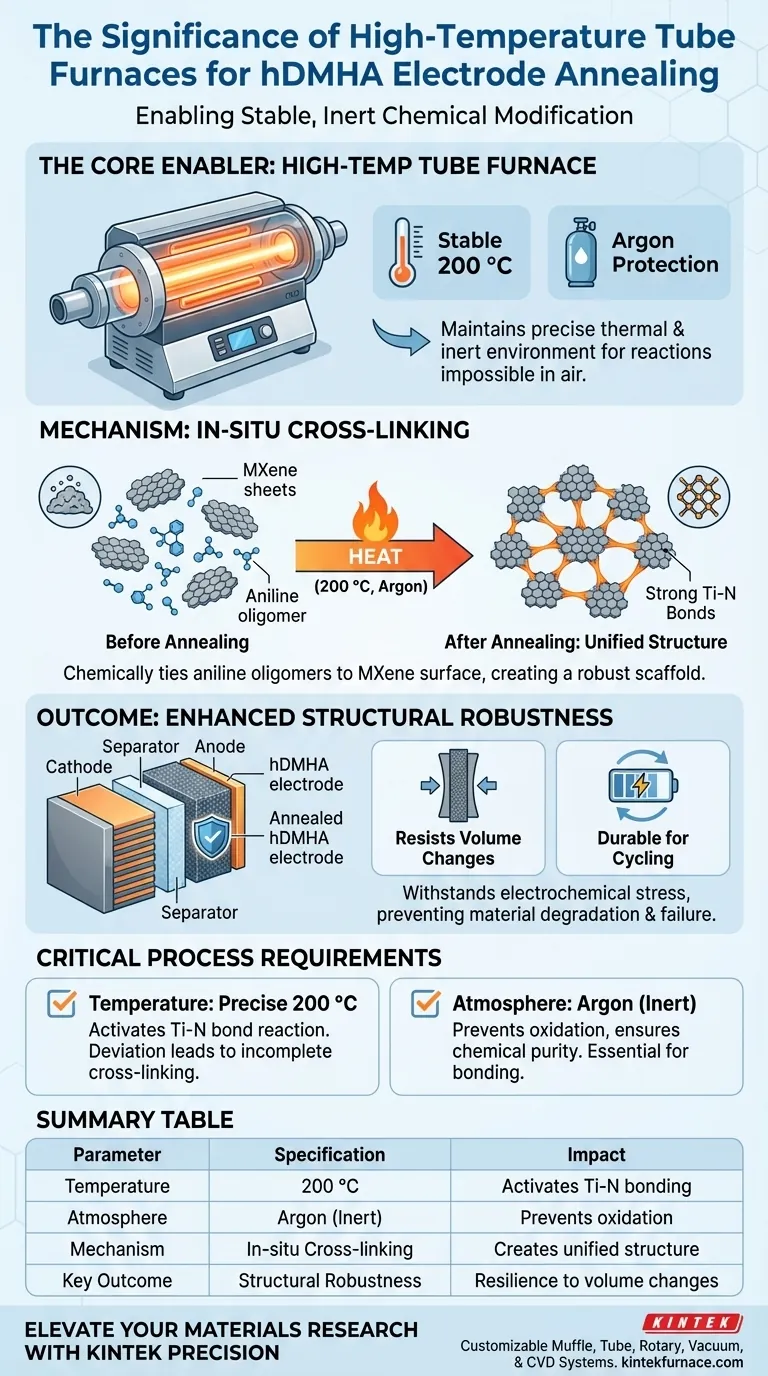

The primary significance of using a high-temperature tube furnace is its ability to create a highly stable, inert environment essential for chemical modification. Specifically, for densified MXene (hDMHA) electrodes, this equipment maintains argon protection at temperatures around 200 °C, facilitating reactions that are impossible to achieve under standard atmospheric conditions.

Core Takeaway The tube furnace is the enabler of in-situ cross-linking. By providing a controlled thermal environment, it allows aniline oligomers to form strong Ti-N bonds with the MXene surface, transforming the electrode into a mechanically robust structure capable of surviving repeated battery cycling.

The Mechanism of In-Situ Cross-Linking

Establishing the Reactive Environment

The thermal annealing process requires strict environmental controls to succeed. A high-temperature tube furnace is used to provide a stable thermal environment at precisely 200 °C.

Crucially, this heating occurs under argon protection. This inert atmosphere prevents oxidation or contamination, ensuring that the thermal energy drives the intended chemical changes rather than degrading the material.

Formation of Chemical Bonds

The heat generated by the furnace induces specific chemical interactions within the electrode material.

This energy triggers the formation of Ti-N bonds (Titanium-Nitrogen bonds). These bonds form directly between the MXene surface and aniline oligomers present in the composite.

This process is referred to as in-situ cross-linking. It chemically ties the components together, creating a unified structure rather than a simple physical mixture.

Enhancing Electrode Durability

Improving Structural Robustness

The direct result of this furnace-driven cross-linking is a significant enhancement in structural robustness.

The chemical bonds created during annealing act as a scaffold. This strengthens the overall integrity of the hDMHA electrode, making it more resistant to physical stress.

Withstanding Volume Changes

In electrochemical applications, electrodes often swell and shrink during operation. The cross-linked structure allows the electrode to withstand significant volume changes.

This is critical for longevity during electrochemical charge and discharge cycles. Without this thermal treatment, the mechanical stress of cycling could lead to material degradation or failure.

Critical Process Requirements

Dependence on Atmosphere Control

The efficacy of this process is entirely dependent on the argon protection provided by the furnace.

If the inert atmosphere is compromised, the specific Ti-N bonding required for structural reinforcement may not occur, or the MXene could oxidize.

Thermal Specificity

The process relies on maintaining a specific temperature of 200 °C.

This thermal threshold is necessary to activate the reaction between the MXene and the aniline oligomers. Deviating from this temperature could result in incomplete cross-linking, rendering the electrode less robust against volume expansion.

Applying This to Your Fabrication Process

To maximize the performance of your hDMHA electrodes, consider these specific goals:

- If your primary focus is mechanical longevity: Ensure your annealing process holds strictly at 200 °C to fully activate the in-situ cross-linking required to resist volume expansion.

- If your primary focus is chemical purity: Verify the integrity of the argon atmosphere within the tube furnace to facilitate Ti-N bonding without introducing oxides.

Controlled thermal annealing is the decisive step that transitions MXene from a raw material into a durable, cycle-ready electrode component.

Summary Table:

| Parameter | Specification/Requirement | Impact on hDMHA Electrodes |

|---|---|---|

| Temperature | Precisely 200 °C | Activates chemical reaction for Ti-N bonding |

| Atmosphere | Argon (Inert) Protection | Prevents oxidation; ensures chemical purity |

| Mechanism | In-situ Cross-linking | Chemically ties aniline oligomers to MXene surface |

| Key Outcome | Structural Robustness | Resilience against volume changes during cycling |

Elevate Your Materials Research with KINTEK Precision

Unlock the full potential of your electrode fabrication with KINTEK’s high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of MXene annealing and in-situ cross-linking.

Whether you need precise 200 °C stability or advanced inert gas control, our lab high-temp furnaces provide the reliability your research deserves. Contact KINTEK today to discuss your unique needs and see how our expertise can drive your innovation forward.

Visual Guide

References

- Boya Zhang, Ying Tao. Unlocking Unprecedented Gravimetric Capacitance in Thick Electrodes Through Conformal Densification of Robust MXene Hydrogels. DOI: 10.1002/adfm.202511313

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents