At its core, the refractory lining is the critical protective barrier inside a rotary kiln electric furnace. This specialized, heat-resistant layer insulates the furnace's outer steel shell from extreme internal temperatures, corrosive materials, and abrasive forces. Its presence is fundamental to the furnace's basic operation, overall efficiency, and structural lifespan.

The significance of the refractory lining extends far beyond simple heat protection. It is the core component that enables the furnace to operate efficiently and safely, directly influencing energy consumption, product quality, and the long-term structural integrity of the entire system.

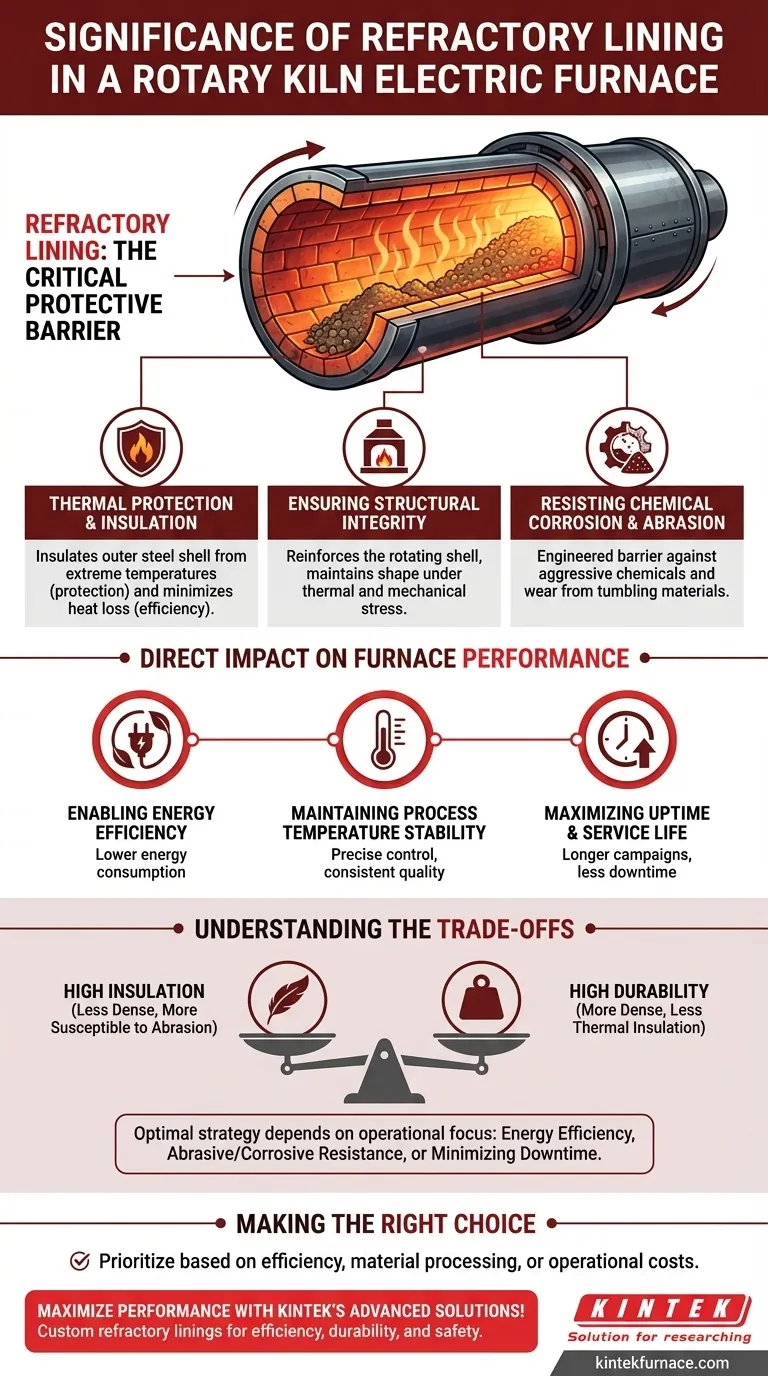

The Foundational Roles of the Refractory Lining

The lining is not a passive component but an active system that performs several critical functions simultaneously. Understanding these roles reveals why it is indispensable.

Thermal Protection and Insulation

The primary function of the refractory lining is to contain the immense heat generated by the electric heating elements. It protects the outer carbon steel shell from temperatures that would otherwise cause it to weaken, deform, or melt.

This function is twofold: it provides a thermal barrier for protection and thermal insulation for efficiency. By keeping the heat concentrated within the processing zone, it prevents energy from escaping through the furnace shell.

Ensuring Structural Integrity

A rotary kiln is a massive, rotating piece of equipment. The refractory lining adds significant structural reinforcement to the cylindrical shell.

It helps the furnace maintain its shape under immense thermal and mechanical stress, ensuring the durability and long-term reliability required for continuous, high-temperature operations. Without it, the shell would quickly fail.

Resisting Chemical Corrosion and Abrasion

The materials processed in a kiln are often chemically aggressive at high temperatures. The refractory lining is engineered to be a corrosion-resistant barrier, protecting the steel shell from chemical attack.

Furthermore, in a rotary kiln, the processed material is constantly tumbling. The lining must be hard enough to withstand this constant abrasive wear, which would quickly erode an unprotected shell.

How the Lining Directly Impacts Furnace Performance

The quality and condition of the refractory lining have a direct and measurable impact on the furnace's operational effectiveness and economic viability.

Enabling Energy Efficiency

The insulative properties of the lining are key to the energy efficiency of an electric furnace. A well-designed lining minimizes heat loss to the outside environment, meaning less electrical energy is required to achieve and maintain the target process temperature.

Maintaining Process Temperature Stability

For many applications, product quality depends on precise and uniform temperature. The refractory lining creates a stable thermal environment, allowing for the precise temperature control that electric furnaces are known for.

A degraded lining leads to cold spots and temperature fluctuations, which can result in inconsistent or low-quality final products.

Maximizing Uptime and Service Life

The lifespan of the refractory lining is often the determining factor in a furnace's maintenance schedule. A durable, properly installed lining leads to longer campaigns and less downtime for repairs.

Proactive monitoring and maintenance of the lining are crucial for maximizing the service life of the entire furnace system.

Understanding the Trade-offs

Selecting and maintaining a refractory lining involves balancing competing priorities. There is no single "best" solution for every application.

The Balance Between Insulation and Durability

Refractory materials that are excellent insulators are often less dense and more susceptible to abrasion. Conversely, highly durable, dense materials may offer less thermal insulation.

The choice of material—such as bricks or castable cement—depends entirely on the specific process. An operation with highly abrasive material may sacrifice some insulation for superior wear resistance.

The Cost of Lining Failure

A failure in the refractory lining is never a minor issue. It can lead to a "hot spot" on the furnace shell, causing immediate structural damage and forcing a complete shutdown.

In the worst-case scenario, a catastrophic failure can destroy the shell, leading to lengthy, expensive repairs and significant production loss. The cost of a proper lining is an investment against this risk.

Making the Right Choice for Your Goal

The optimal refractory strategy depends on your primary operational objective.

- If your primary focus is maximizing energy efficiency: Prioritize refractories with high insulative properties (low thermal conductivity), even if it requires more frequent monitoring for wear.

- If your primary focus is processing highly abrasive or corrosive materials: Select dense, high-durability refractories designed to withstand chemical and physical attack, accepting potentially lower thermal insulation.

- If your primary focus is minimizing downtime and operational cost: Implement a proactive maintenance and inspection schedule, as the lining's integrity is the single greatest factor in preventing catastrophic furnace failure.

Ultimately, viewing the refractory lining as an engineered, active component—not just a passive barrier—is the key to unlocking the full potential of your furnace operation.

Summary Table:

| Function | Impact |

|---|---|

| Thermal Protection | Shields steel shell from extreme heat, reduces energy loss |

| Structural Integrity | Reinforces furnace, prevents deformation under stress |

| Chemical/Abrasion Resistance | Protects against corrosive materials and wear |

| Energy Efficiency | Minimizes heat loss, lowers electricity consumption |

| Temperature Stability | Ensures precise control for consistent product quality |

| Uptime and Lifespan | Reduces downtime, extends overall furnace service life |

Maximize your furnace's performance with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise refractory linings tailored to your unique needs, enhancing efficiency, durability, and safety. Contact us today to discuss how we can optimize your operations and deliver reliable, long-lasting results!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems