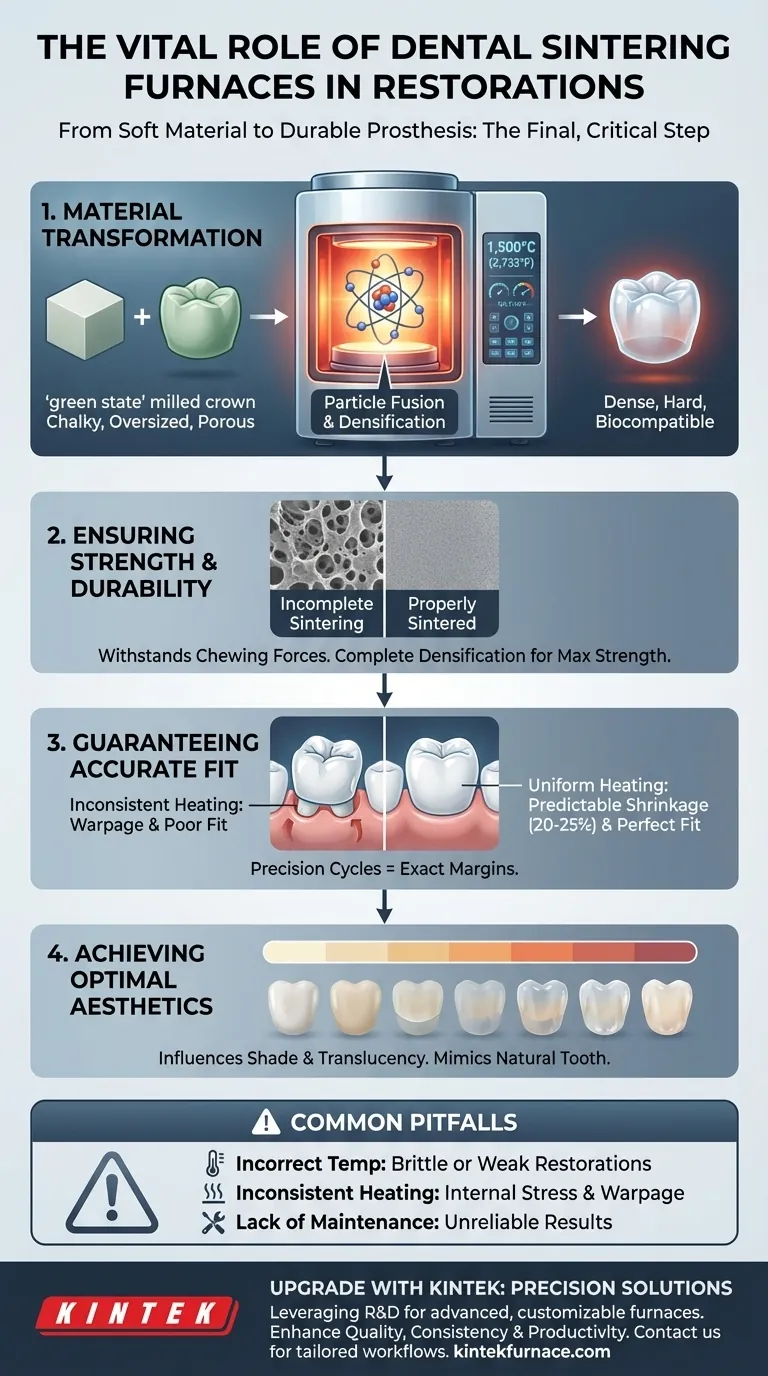

In modern dentistry, the sintering furnace is the final, critical step that transforms a soft, milled restoration into a functional and durable prosthesis. These specialized high-temperature ovens use precisely controlled heating cycles to convert materials like zirconia from a porous, chalk-like state into a dense, hard structure suitable for clinical use. Without this process, a digitally designed and milled crown or bridge would lack the necessary strength and stability for the oral environment.

A dental furnace's role extends far beyond simple heating. It is a precision instrument that controls a material's transformation at a molecular level, directly determining the final restoration's strength, fit, and aesthetic quality. The success of the entire digital workflow hinges on this final, crucial step.

From Digital File to Physical Function

The journey of a modern restoration, like a zirconia crown, involves a critical physical transformation that happens entirely within the sintering furnace. It’s the bridge between the digital design and the final, clinically acceptable part.

The "Green State": What Goes In

After being milled from a zirconia puck based on a CAD design, the restoration is in its "green" or "pre-sintered" state. It is chalky, oversized, and fragile. This initial form is easy to mill but completely unsuitable for use in the mouth.

The Sintering Transformation

Inside the furnace, the restoration is heated to temperatures often exceeding 1,500°C (2,732°F). During this process, the individual particles of zirconia fuse together, eliminating the pores between them. This causes the material to densify and shrink in a highly predictable manner, typically by 20-25%.

The Final Product: What Comes Out

The result is a restoration that is incredibly hard, strong, and biocompatible. The process also significantly enhances the material's translucency, allowing it to mimic the appearance of a natural tooth. The part is now at its final, correct size and ready for staining, glazing, or polishing.

The Critical Link to Clinical Quality

The furnace is not just a piece of equipment; it is an active partner in quality control. The precision of the sintering cycle has a direct and profound impact on the final clinical outcome.

Ensuring Material Strength and Durability

The final strength of the zirconia is determined by how well it was sintered. A properly executed heating cycle ensures complete densification, resulting in a restoration that can withstand the immense chewing forces in the mouth.

Guaranteeing an Accurate Fit

Predictable shrinkage is essential for a crown or bridge to fit perfectly. Modern furnaces follow precise, pre-programmed cycles designed for specific materials, ensuring that the shrinkage is uniform and the final fit is exact. Inaccurate heating can cause warpage and poor marginal fit.

Achieving Optimal Aesthetics

The sintering process also influences the optical properties of the material. The temperature and duration of the cycle affect the final shade and translucency, which are critical for matching the restoration to the patient's existing teeth.

Common Pitfalls and Trade-offs

While essential, the sintering process is sensitive. Errors or equipment shortcomings can compromise the entire restoration, wasting time and resources.

The Risk of Incorrect Temperature

Using a temperature that is too high can cause grain growth, making the zirconia brittle. A temperature that is too low will result in incomplete sintering, leaving the restoration weak, porous, and prone to failure.

The Impact of Inconsistent Heating

Furnaces must provide perfectly uniform heat. If "hot spots" or "cold spots" exist within the chamber, the restoration will shrink unevenly, leading to internal stress, warpage, and an inaccurate fit that cannot be corrected.

The Need for Consistent Maintenance

Dental furnaces require regular calibration to ensure their temperature readings are accurate. An uncalibrated furnace will fail to produce consistent results, undermining the reliability of the entire digital workflow.

Making the Right Choice for Your Goal

Your approach to sintering should directly align with the primary objectives of your clinic or laboratory.

- If your primary focus is maximum quality and consistency: Prioritize furnaces with documented temperature accuracy and advanced heating elements to guarantee uniform, predictable outcomes every time.

- If your primary focus is productivity and turnaround time: Look for models with reliable "fast sintering" cycles, but verify that these cycles do not compromise the material's final strength or aesthetics.

- If your primary focus is bringing production in-house: Factor in the total cost of ownership, including maintenance and energy use, to ensure the investment provides real cost and time savings over outsourcing.

Ultimately, mastering the sintering process is fundamental to delivering dental restorations that are not just made, but expertly engineered for clinical success.

Summary Table:

| Aspect | Role in Dental Restorations |

|---|---|

| Material Transformation | Converts soft, porous zirconia to dense, hard structure via high-temperature sintering (up to 1,500°C). |

| Strength & Durability | Ensures restorations withstand chewing forces through complete densification and uniform shrinkage (20-25%). |

| Fit & Precision | Provides predictable shrinkage for accurate crown/bridge fit, avoiding warpage and poor margins. |

| Aesthetics | Enhances translucency and shade for natural tooth appearance, influenced by temperature control. |

| Common Risks | Incorrect temperature or inconsistent heating can lead to brittleness, weakness, or fit issues. |

Upgrade your dental lab with precision sintering solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we offer advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures these products meet your unique experimental needs, enhancing restoration quality, consistency, and productivity. Contact us today to discuss how our tailored furnace solutions can optimize your dental workflows and deliver superior clinical outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision