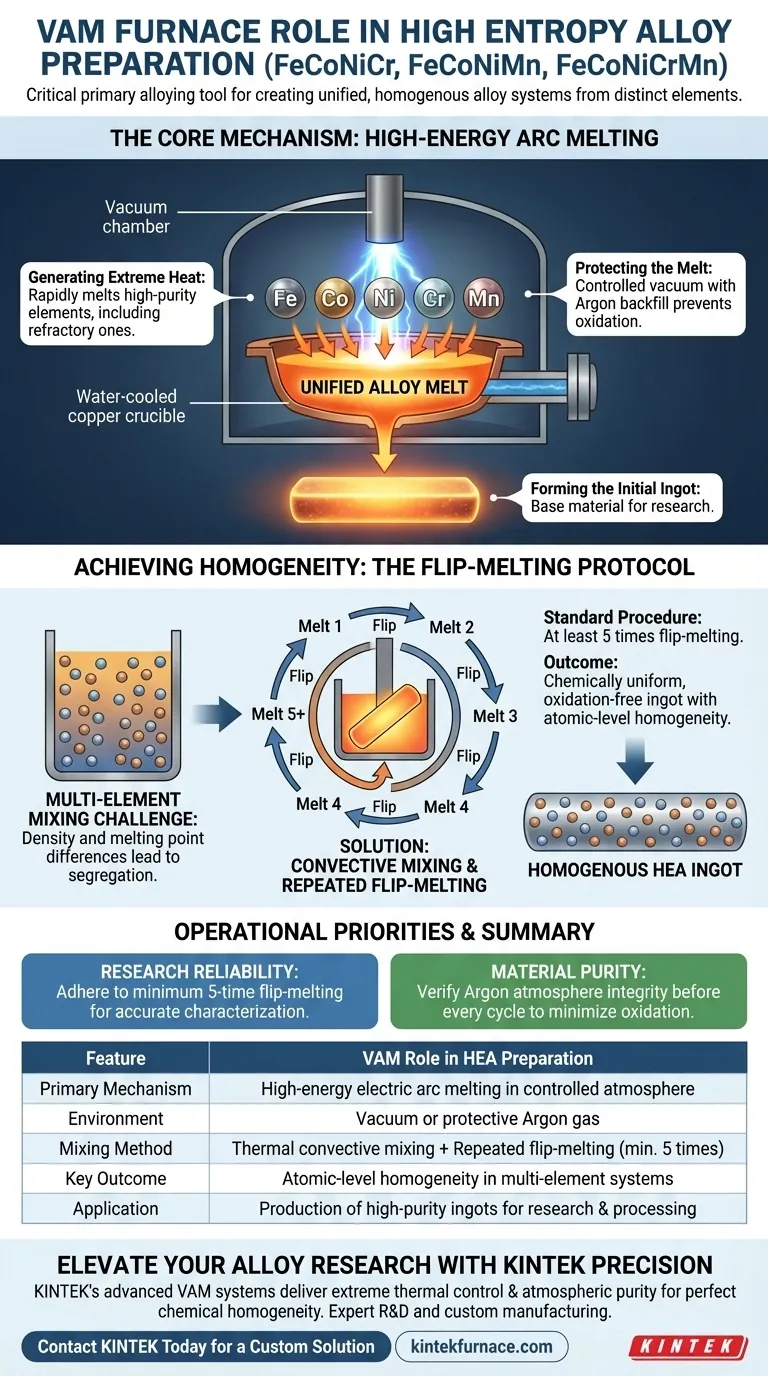

The Vacuum Arc Melting (VAM) furnace serves as the critical primary alloying tool for creating medium and high entropy alloys like FeCoNiCr and FeCoNiCrMn. It utilizes high-energy electric arcs to rapidly melt high-purity metallic elements under a protective argon atmosphere, converting raw distinct elements into a unified alloy system.

Core Takeaway The creation of high entropy alloys requires overcoming the natural tendency of multiple elements to segregate. The VAM furnace addresses this by employing a "repeated flip-melting" process—melting the material at least five times—to force thorough convective mixing and guarantee a chemically uniform, oxidation-free ingot.

The Core Mechanism: High-Energy Arc Melting

Generating Extreme Heat

The furnace employs high-energy arcs to generate the intense heat necessary to melt high-purity metallic elements. This rapid melting capability is essential for processing refractory elements often found in high entropy alloys.

Protecting the Melt

The entire melting process takes place within a controlled vacuum environment backfilled with a protective argon atmosphere. This prevents the molten metals from reacting with oxygen, ensuring that the purity of the raw materials is maintained in the final alloy.

Forming the Initial Ingot

The primary output of this stage is a preliminary alloy ingot. This ingot serves as the fundamental "base material" for all subsequent research or processing steps.

Achieving Homogeneity through Process Control

The Challenge of Multi-Element Mixing

In alloys containing four or five distinct elements (such as Fe, Co, Ni, Cr, and Mn), achieving a uniform distribution of atoms is difficult. Without intervention, elements with different densities or melting points may separate or settle unevenly.

Convective Mixing in the Liquid State

The VAM furnace solves this segregation issue by maintaining the metal in a liquid state long enough to induce convective mixing. The thermal currents within the molten pool physically circulate the different elements, encouraging them to blend at the atomic level.

The Critical "Flip-Melting" Protocol

A single melt is rarely sufficient for high entropy alloys. The standard operating procedure requires repeated flip-melting, typically performed at least five times. By melting the ingot, flipping it over, and melting it again, the furnace ensures that every portion of the material undergoes the same thermal history and mixing intensity.

Understanding the Operational Requirements

The Necessity of Iteration

The high uniformity of VAM ingots comes at the cost of processing time. The requirement to flip and remelt the material multiple times is not an optional step; it is a mandatory constraint to ensure the chemical composition is consistent throughout the bulk material.

Determining Downstream Success

The quality of the VAM ingot dictates the reliability of all future data. If the initial convective mixing is insufficient, the chemical composition will vary across the sample, rendering subsequent research into the alloy's mechanical or physical properties invalid.

Making the Right Choice for Your Goal

When utilizing a Vacuum Arc Melting Furnace for high entropy alloy preparation, focus on these operational priorities:

- If your primary focus is Research Reliability: Adhere strictly to the minimum five-time flip-melting protocol to ensure the chemical uniformity required for accurate characterization.

- If your primary focus is Material Purity: Verify the integrity of the argon protective atmosphere before every cycle to minimize oxidation contamination, particularly when using reactive elements like Manganese or Chromium.

The VAM furnace is not just a heat source; it is a mixing device that transforms distinct elemental ingredients into a singular, homogenous alloy ready for scientific investigation.

Summary Table:

| Feature | VAM Role in HEA Preparation |

|---|---|

| Primary Mechanism | High-energy electric arc melting in a controlled atmosphere |

| Environment | Vacuum or protective argon gas to prevent oxidation |

| Mixing Method | Thermal convective mixing + repeated flip-melting (min. 5 times) |

| Key Outcome | Atomic-level homogeneity in multi-element systems (Fe, Co, Ni, Cr, Mn) |

| Application | Production of high-purity ingots for research and downstream processing |

Elevate Your Alloy Research with KINTEK Precision

Ready to master the complexities of FeCoNiCr and other high entropy alloys? KINTEK’s advanced Vacuum Arc Melting systems are engineered to deliver the extreme thermal control and atmospheric purity required for perfect chemical homogeneity.

Backed by expert R&D and manufacturing, we offer a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your specific laboratory needs. Don't let elemental segregation compromise your data—leverage our high-temp expertise to produce superior materials.

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Chao-hong Wang, Yue-Han Li. Liquid-State Interfacial Reactions of Lead-Free Solders with FeCoNiCr and FeCoNiMn Medium-Entropy Alloys at 250 °C. DOI: 10.3390/ma18102379

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role do high-power heating plates play in vacuum contact drying furnaces? Unlock Rapid Thermal Diffusion

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering