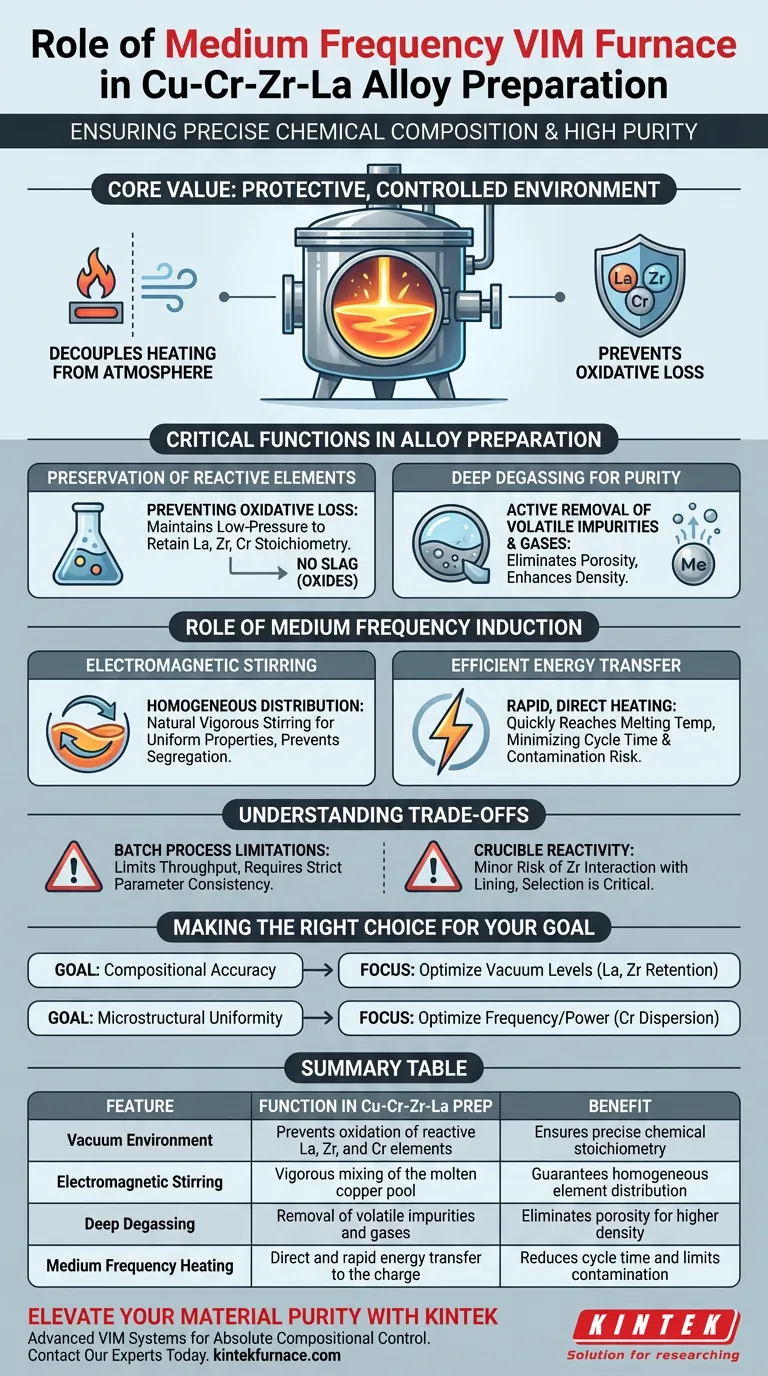

The primary role of a medium frequency vacuum induction melting (VIM) furnace is to ensure the precise chemical composition and high purity of Cu-Cr-Zr-La alloys by creating a protective, controlled environment. It utilizes electromagnetic principles to melt and stir the metal while strictly preventing the degradation of reactive alloying elements.

The core value of this furnace lies in its ability to decouple the heating process from atmospheric contamination. By operating in a vacuum, it prevents the oxidative loss of Lanthanum, Zirconium, and Chromium, ensuring the final ingot retains the exact stoichiometry required for high-performance applications.

Critical Functions in Alloy Preparation

The preparation of Cu-Cr-Zr-La (Copper-Chromium-Zirconium-Lanthanum) is technically demanding due to the reactivity of its components. The furnace addresses these challenges through three specific mechanisms.

Preservation of Reactive Elements

The most significant challenge in this alloy system is the high reactivity of Lanthanum (La), Zirconium (Zr), and Chromium (Cr).

Preventing Oxidative Loss

When exposed to oxygen at melting temperatures, these elements oxidize rapidly. Without a vacuum environment, significant amounts of La, Zr, and Cr would be lost as slag (oxides) rather than dissolving into the copper matrix. The VIM furnace mitigates this by maintaining a low-pressure environment, ensuring the final alloy retains the precise chemical composition intended by the formulation.

Deep Degassing for Purity

The vacuum environment performs a critical "cleaning" function known as degassing. It actively removes volatile impurities and gaseous byproducts from the liquid metal. This eliminates the risk of porosity in the final ingot, directly enhancing the density and microstructural integrity of the material.

The Role of Medium Frequency Induction

While the vacuum protects the chemistry, the medium frequency induction mechanism drives the physical quality of the melt.

Electromagnetic Stirring

Induction heating generates strong electromagnetic forces within the molten pool. This causes a natural, vigorous stirring action without the need for physical mechanical stirrers. For Cu-Cr-Zr-La alloys, this ensures a homogeneous distribution of the alloying elements, preventing segregation and ensuring uniform properties throughout the ingot.

Efficient Energy Transfer

Medium frequency induction provides rapid, direct heating to the metal charge. This efficiency allows the system to reach required melting temperatures quickly, minimizing the total time the metal spends in a molten state. Reduced cycle times further lower the risk of incidental contamination or crucible reactions.

Understanding the Trade-offs

While VIM is the superior choice for this alloy, it is important to recognize the operational constraints.

Batch Process Limitations

VIM is typically a batch process, which limits throughput compared to continuous casting methods. This requires strict consistency in operational parameters (vacuum levels, power input) from batch to batch to ensure reproducibility.

Crucible Reactivity

Although the vacuum removes air, the molten metal is still in contact with the crucible lining. At high temperatures, there is a minor risk of the reactive elements (especially Zirconium) interacting with the crucible material. Selecting the correct refractory lining is just as critical as the vacuum pressure itself.

Making the Right Choice for Your Goal

The use of a medium frequency VIM furnace is not just about melting; it is about chemical control.

- If your primary focus is Compositional Accuracy: Rely on the vacuum levels to strictly control the retention rates of Lanthanum and Zirconium, as these are the first to oxidize.

- If your primary focus is Microstructural Uniformity: Optimize the frequency and power settings to maximize the electromagnetic stirring effect, ensuring the Chromium is evenly dispersed.

Ultimately, this furnace serves as a purification tool, allowing you to synthesize complex copper alloys that would be impossible to produce in open-air induction systems.

Summary Table:

| Feature | Function in Cu-Cr-Zr-La Preparation | Benefit |

|---|---|---|

| Vacuum Environment | Prevents oxidation of reactive La, Zr, and Cr elements | Ensures precise chemical stoichiometry |

| Electromagnetic Stirring | Vigorous mixing of the molten copper pool | Guarantees homogeneous element distribution |

| Deep Degassing | Removal of volatile impurities and gases | Eliminates porosity for higher density |

| Medium Frequency Heating | Direct and rapid energy transfer to the charge | Reduces cycle time and limits contamination |

Elevate Your Material Purity with KINTEK

Precision is non-negotiable when synthesizing complex alloys like Cu-Cr-Zr-La. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Vacuum Induction Melting (VIM) systems, alongside our specialized Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to your specific research or production needs. Ensure absolute compositional control and microstructural integrity in your high-temperature processes.

Contact Our Experts Today to Discuss Your Custom Alloy Needs

Visual Guide

References

- Hairui Zhi, Haitao Zhao. Low cycle fatigue behavior of Cu-Cr-Zr-La alloys. DOI: 10.1088/1742-6596/2951/1/012133

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How do induction furnaces improve working conditions? A Safer, Cleaner Foundry Environment

- What is annealing and how does induction heating facilitate it? Achieve Precise, Efficient Heat Treatment

- What is the function of a high-temperature vacuum induction furnace in (Hf─Zr─Ti)C synthesis? Achieve 2100°C Precision

- What is the role of a vacuum arc furnace in Sn-Ag-Cu-Mn-Er solder alloy smelting? Precision Melting for Purity

- Why is high-purity argon gas utilized during the melting of AlCoCrFeNi2.1 alloys? Ensure Peak Alloy Purity

- What is the core component of an induction heater and what is it made of? Unlock Efficient, Non-Contact Heating

- What are the advantages of using a high vacuum arc furnace for nickel-based superalloys? Precision & Purity Defined

- Which is better: induction furnace or electric arc furnace? The right tool for your metallurgical mission.