In essence, annealing is a heat treatment process used to make metals softer and more workable. It achieves this by heating a material to a specific temperature and then cooling it slowly, which repairs its internal crystal structure. Induction heating is a highly advanced method for this process because it generates heat directly within the metal itself, offering exceptional speed, precision, and control.

Annealing modifies a material's physical properties to improve its workability. Induction heating is not just another way to apply heat; it is a fundamentally more efficient and controllable method that uses electromagnetic principles to heat the material from the inside out.

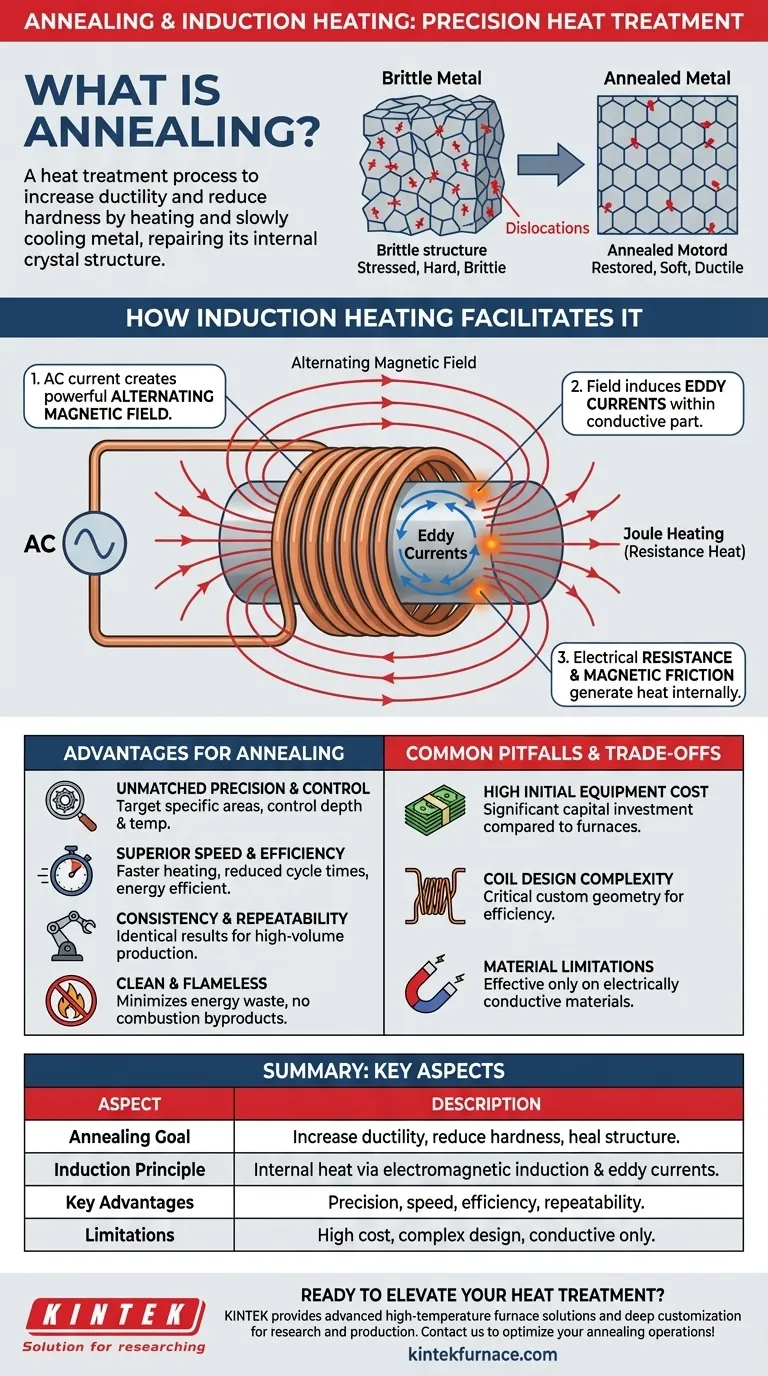

The Goal of Annealing: A Microscopic View

Restoring Ductility and Reducing Hardness

Annealing is performed to increase a material's ductility (its ability to be stretched or shaped without breaking) and reduce its hardness. This is often necessary after processes like stamping or cold-drawing have made the metal brittle and difficult to work with.

Healing the Crystal Structure

On a microscopic level, metals are made of a crystal lattice. When a metal is bent or stressed, imperfections known as dislocations form and multiply within this structure. These dislocations are what make the material harder and more brittle.

The heat applied during annealing gives the atoms in the crystal lattice enough energy to move, allowing them to rearrange into a more orderly state and effectively "heal" these dislocations. This restored structure is what gives the metal its renewed softness and ductility.

The Mechanics of Induction Heating

The Principle: Generating Heat from Within

Unlike a traditional furnace that heats the surface of a part from the outside, induction heating is a non-contact process that generates heat inside the conductive material itself. This is achieved through electromagnetic induction.

Step 1: The Alternating Magnetic Field

The process begins by passing a high-frequency alternating current (AC) through a copper coil. This creates a powerful and rapidly changing magnetic field in the space within and around the coil.

Step 2: Inducing Eddy Currents

When an electrically conductive part, like a steel component, is placed inside this magnetic field, the field induces circular electrical currents within the metal. These are known as eddy currents.

Step 3: Heat from Resistance (Joule Heating)

As these eddy currents flow through the metal, they encounter the material's natural electrical resistance. This resistance converts the electrical energy into intense, localized heat, a principle known as Joule heating.

An Extra Boost: Magnetic Hysteresis

For ferromagnetic materials like iron, an additional heating effect occurs. The rapidly alternating magnetic field causes the magnetic domains within the material to flip back and forth, creating internal friction and generating even more heat. This is known as magnetic hysteresis loss.

Understanding the Advantages for Annealing

Unmatched Precision and Control

Induction allows for the precise application of heat to very specific areas of a part. By controlling the frequency of the current and the design of the coil, you can dictate exactly where the heat is generated, how deep it penetrates, and the exact temperature reached.

Superior Speed and Efficiency

Because heat is generated instantly within the part, the target temperature is reached much faster than in a conventional furnace. This significantly reduces cycle times. The process is also highly energy-efficient, as energy is not wasted heating the air or walls of a furnace.

Consistency and Repeatability

The process is electronically controlled and highly repeatable. Once a heating profile is established, it can be executed identically thousands of times, ensuring consistent quality in high-volume production environments.

Common Pitfalls and Trade-offs

High Initial Equipment Cost

Induction heating systems, including the power supply and custom coils, represent a significant capital investment compared to traditional furnaces. This cost must be weighed against the long-term benefits of speed and efficiency.

Coil Design Complexity

The geometry of the induction coil is critical and must be carefully designed and fabricated to match the specific part being heated. An improperly designed coil will lead to inefficient or uneven heating, defeating the purpose of the technology.

Material Limitations

This method is only effective on materials that are electrically conductive. It cannot be used to directly heat insulators like plastics or ceramics, though it can be used to heat a conductive vessel containing them, as seen in pyrolysis applications.

Making the Right Choice for Your Process

Deciding to use induction heating for annealing depends entirely on your specific manufacturing goals.

- If your primary focus is high-volume production with consistent quality: The speed and repeatability of induction heating offer a clear advantage over slower batch processes.

- If your primary focus is precise, localized annealing on complex parts: Induction is the superior choice, as it allows you to heat only the required sections without affecting the rest of the component.

- If your primary focus is energy efficiency and a cleaner work environment: The direct, flameless heating of induction minimizes energy waste and eliminates the byproducts of combustion.

Ultimately, choosing induction heating is an investment in precision, speed, and control for your heat treatment operations.

Summary Table:

| Aspect | Description |

|---|---|

| Annealing Goal | Increase ductility, reduce hardness, and heal crystal structure in metals. |

| Induction Principle | Generates heat internally via electromagnetic induction, eddy currents, and Joule heating. |

| Key Advantages | High precision, speed, energy efficiency, and repeatability for consistent results. |

| Limitations | High initial cost, coil design complexity, and limited to conductive materials. |

Ready to elevate your heat treatment process with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Whether you're focused on high-volume production or localized annealing, our technologies ensure superior control and repeatability. Don't settle for less—contact us today to discuss how we can optimize your annealing operations and deliver unmatched value!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity