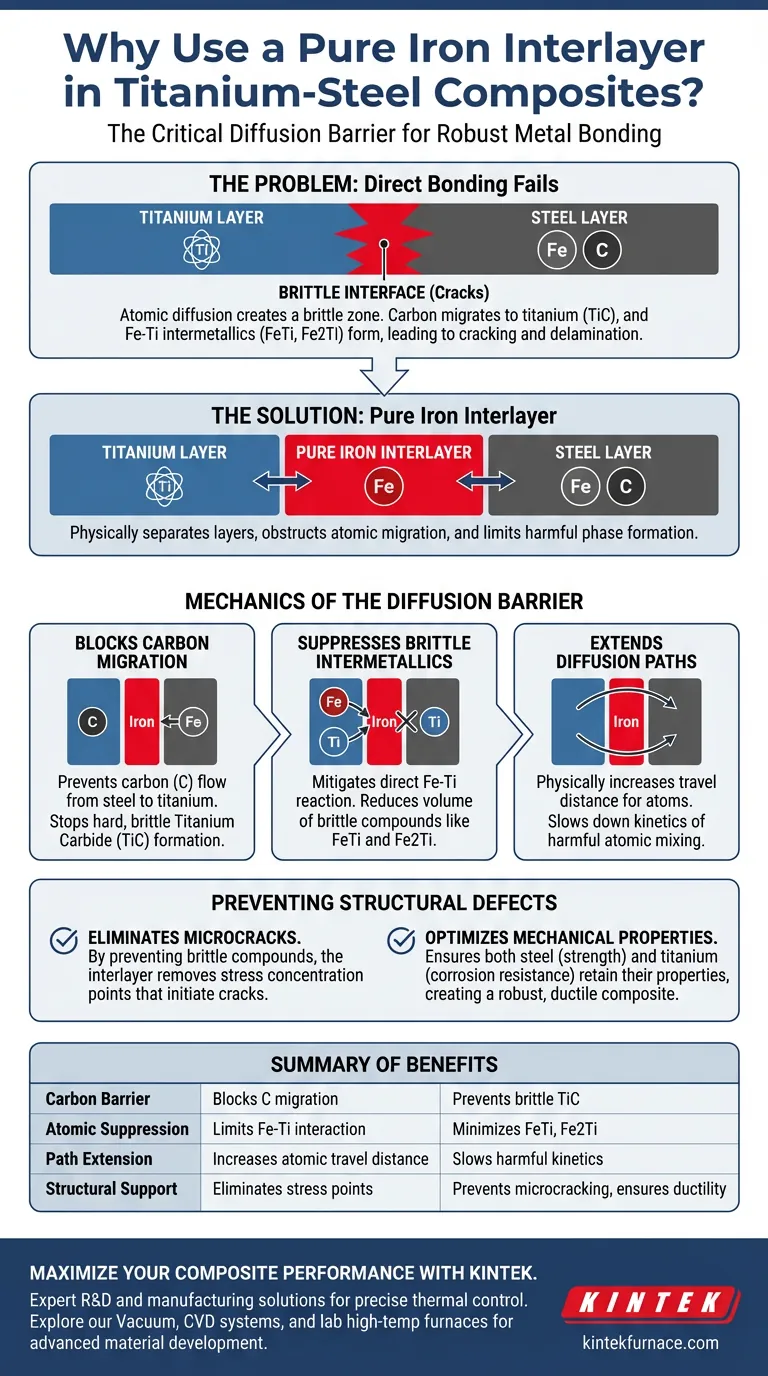

The introduction of a pure iron interlayer serves as a critical diffusion barrier designed to prevent the structural failure of the bond between titanium and steel. By physically separating these two materials, the iron layer obstructs the migration of carbon and limits the interaction of iron and titanium, thereby stopping the formation of brittle phases that lead to cracking.

Core Takeaway Direct bonding between titanium and steel often fails because atomic diffusion creates a brittle interface. The pure iron interlayer solves this by blocking carbon flow and suppressing the formation of dangerous compounds like titanium carbide (TiC) and iron-titanium (FeTi), ensuring the composite plate retains its mechanical integrity and ductility.

The Mechanics of the Diffusion Barrier

Blocking Carbon Migration

The primary function of the pure iron layer is to obstruct the diffusion of carbon from the steel side toward the titanium side.

Titanium has a strong chemical affinity for carbon, and without a barrier, it draws carbon out of the steel.

This migration must be stopped because it leads to the formation of Titanium Carbide (TiC), a hard, brittle ceramic phase that weakens the bond.

Suppressing Brittle Intermetallic Compounds

Beyond carbon, the interlayer mitigates the direct reaction between iron and titanium atoms.

When these elements mix freely at high temperatures, they form brittle intermetallic compounds, specifically iron-titanium (FeTi) and diiron titanium (Fe2Ti).

By reducing the volume of these compounds, the interlayer prevents the interface from becoming glass-like and prone to shattering under stress.

Extending Diffusion Paths

The presence of the interlayer physically extends the distance that iron, titanium, and carbon atoms must travel to interact.

This "extension of diffusion paths" effectively slows down the kinetics of atomic mixing.

The result is a more stable interface where harmful reactions are significantly delayed or minimized.

Preventing Structural Defects

Eliminating Microcracks

Brittle compounds (TiC, FeTi) create localized points of high hardness and low ductility within the metal.

These points act as stress concentrators, which are the initiation sites for microcracks.

By preventing the formation of these compounds, the pure iron interlayer stops these microcracks from forming, preserving the structural continuity of the clad plate.

Optimizing Mechanical Properties

The ultimate goal of using the interlayer is to maintain the desirable properties of both base metals.

It ensures the steel retains its strength and the titanium retains its corrosion resistance, without the bond between them becoming the weak link.

This results in a composite plate that can withstand thermal and mechanical stress without delaminating.

Understanding the Trade-offs

Material Purity Requirements

For this technique to work, the iron interlayer must be chemically "pure."

If the iron interlayer itself contains significant carbon or impurities, it will fail to act as a barrier and may contribute to the very embrittlement it is meant to solve.

Sourcing high-purity iron adds a specific material constraint to the supply chain.

Manufacturing Complexity

Introducing a third layer changes the manufacturing process from a two-ply to a three-ply composite.

This requires precise control over the thickness and placement of the interlayer during the rolling or cladding process.

Any inconsistency in the iron layer's thickness could create weak spots where diffusion can still occur.

Making the Right Choice for Your Project

The decision to use an interlayer is driven by the need for reliability over simplicity.

- If your primary focus is bond integrity: Use a pure iron interlayer to eliminate the risk of delamination caused by brittle intermetallic phases.

- If your primary focus is mechanical longevity: Rely on the interlayer to prevent stress concentration and microcracking under load.

By controlling the chemistry at the interface, the pure iron interlayer transforms a fragile mix of metals into a robust, high-performance composite.

Summary Table:

| Function | Mechanism | Benefit |

|---|---|---|

| Carbon Barrier | Blocks carbon migration from steel to titanium | Prevents formation of brittle Titanium Carbide (TiC) |

| Atomic Suppression | Limits direct interaction between Fe and Ti atoms | Minimizes brittle intermetallic compounds like FeTi and Fe2Ti |

| Path Extension | Increases the physical distance for atomic travel | Slows down harmful reaction kinetics at the interface |

| Structural Support | Eliminates stress concentration points | Prevents microcracking and ensures mechanical ductility |

Maximize Your Composite Performance with KINTEK

Ensure your advanced materials withstand the toughest environments. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum, CVD systems, and lab high-temp furnaces designed to provide the precise thermal control needed for high-quality metal cladding and material research.

Whether you are developing titanium-steel composites or specialized alloys, our customizable systems are engineered to meet your unique laboratory and production needs.

Ready to elevate your material integrity? Contact us today to discuss your project requirements!

Visual Guide

References

- Juan Pu, Yunxia Chen. Effect of Heat Treatment Temperature on the Microstructure and Properties of Titanium-Clad Steel Plate Prepared by Vacuum Hot Rolling. DOI: 10.3390/coatings14091096

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- How is the graphitization degree quantified using Raman spectroscopy? Master the $I_D/I_G$ Ratio for Carbon Materials

- How does a high-temperature laboratory furnace facilitate the pressureless sintering (PLS) of silicon nitride ceramics?

- What additional benefits do vacuum chambers provide beyond environmental control? Enhance Material Purity and Process Efficiency

- Why are different cooling methods compared for GFRP post-fire performance? Evaluate Thermal Shock & Safety Risks

- What are the advantages of Flash Lamp Annealing (FLA)? Unlock High-Performance Films on Heat-Sensitive Substrates

- What is the function of an industrial drying oven in ZnZrOx catalyst prep? Ensure Uniform Metal Precursor Adsorption

- What role does a high-performance blast drying oven play in the hydrothermal reaction stage of CoO/CoSe nanoparticles?

- How does a blast drying oven affect the preparation of BN-C precursors? Optimize Structural Stability and Homogeneity