The primary purpose of a rotary furnace is to heat loose or granular materials uniformly through continuous mixing. By rotating a tilted cylindrical chamber, the furnace ensures that every particle is consistently exposed to the heat source, enabling reliable physiochemical processing like the roasting of catalysts on an industrial scale.

A rotary furnace solves a fundamental challenge in thermal processing: how to heat a large volume of loose material evenly. Its design combines rotation for constant mixing with a slight tilt for continuous material flow, making it an exceptionally efficient tool for high-throughput, uniform production.

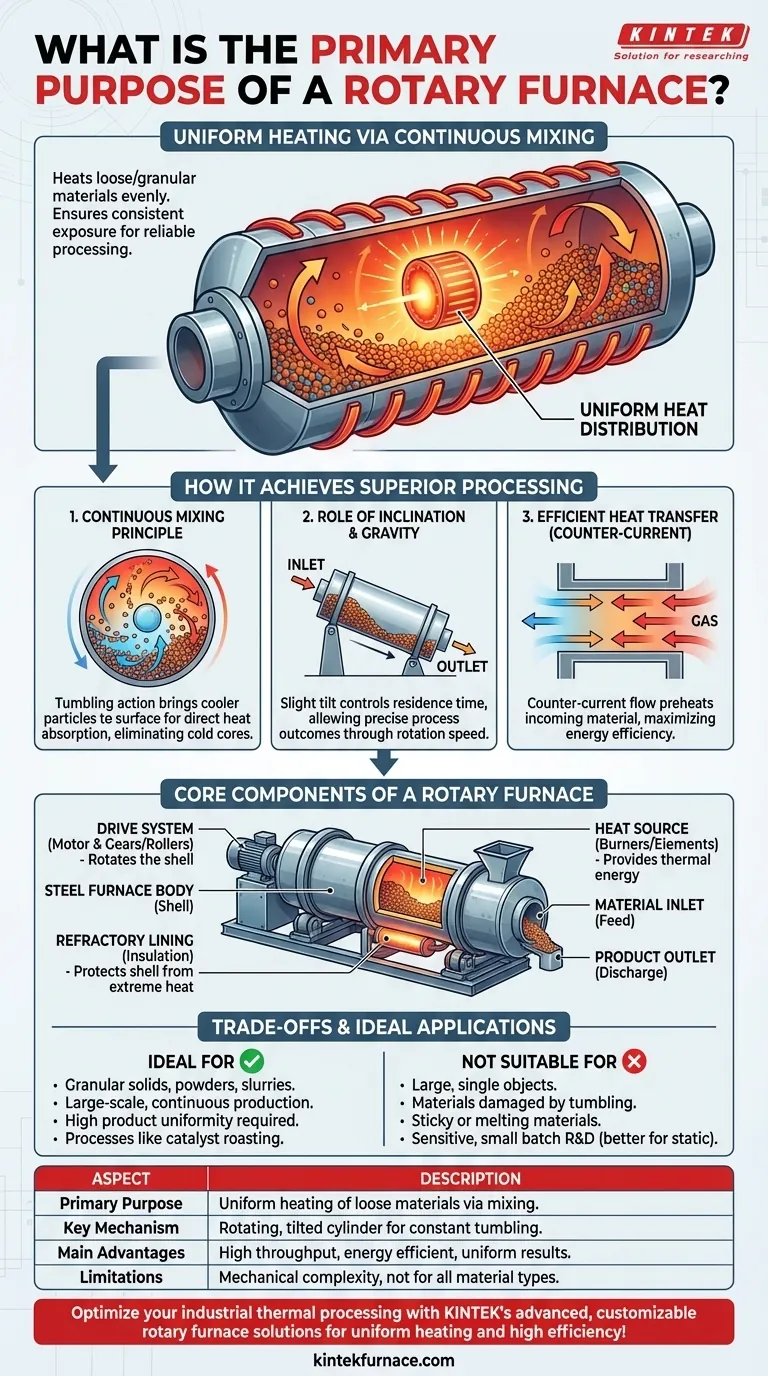

How a Rotary Furnace Achieves Superior Processing

A static, or box, furnace heats material in a fixed position, often leading to hot spots on the outside of the pile and a cooler, unprocessed core. The rotary furnace's design directly overcomes this limitation.

The Principle of Continuous Mixing

The core of the furnace is a cylindrical tube that rotates along its axis. As it turns, the material inside is lifted and tumbles over itself.

This constant mixing action continuously brings cooler particles from the center of the mass to the surface, where they can absorb heat directly. This guarantees a highly uniform temperature throughout the entire batch of material.

The Role of Inclination

Most rotary furnaces are mounted at a slight angle. This tilt uses gravity to move material steadily from the inlet at the higher end to the outlet at the lower end.

The combination of rotation speed and tilt angle gives operators precise control over the residence time—the amount of time the material spends inside the furnace. This control is critical for achieving specific process outcomes.

Efficient Heat Transfer

Heat is typically generated by gas burners or electric elements and flows through the furnace chamber. In many designs, hot gases flow in the opposite direction of the material (counter-current flow).

This counter-current design is highly efficient. The hottest gases encounter the most processed material near the exit, while the cooler, exiting gases preheat the new material entering the furnace, minimizing wasted energy.

The Core Components of a Rotary Furnace

Understanding the key parts of the furnace reveals how it functions as an integrated system for industrial processing.

Furnace Body and Lining

The furnace body is a long, cylindrical shell, typically fabricated from welded steel plate.

Inside this shell is a crucial refractory lining made of specialized bricks or castable cement. This lining insulates the steel body from extreme internal temperatures (often exceeding 1000°C) and protects it from chemical corrosion or abrasion from the material being processed.

The Drive System

An electric motor connected to a drive gear or a set of driven rollers rotates the furnace body.

Modern systems feature variable speed control, allowing operators to fine-tune the tumbling action. Slower rotation may be used for delicate materials, while faster rotation increases mixing intensity.

The Heat Source

The heat source can be either direct-fired using gas or oil burners or indirect, using electric heating elements arranged around the outside of the furnace tube. The method of heat transfer is a combination of conduction, convection, and radiation.

Understanding the Trade-offs

While highly effective, the rotary furnace design has specific trade-offs that make it suitable for some applications but not others.

Mechanical Complexity

The rotating shell, seals, drive gear, and support rollers make a rotary furnace mechanically more complex than a simple static furnace. This can translate to higher initial investment and more specialized maintenance requirements.

Material Suitability

This design is ideal for granular solids, powders, and slurries. It is not suitable for large, single objects or for materials that could be damaged by the tumbling action. Likewise, materials that become sticky or melt at processing temperatures can cause significant operational problems.

Process Control

While offering excellent temperature uniformity within the material bed, achieving a highly specific temperature profile along the length of the furnace requires a sophisticated multi-zone control system. For some sensitive R&D applications, a smaller, precision-controlled batch furnace may be more appropriate.

Making the Right Choice for Your Process

Your decision to use a rotary furnace should be based on your material type, required throughput, and desired product consistency.

- If your primary focus is large-scale, continuous production of powders or granulars: The high throughput and thermal efficiency of a rotary furnace are unmatched.

- If your primary focus is achieving the highest possible product uniformity: The continuous mixing action is a decisive advantage that eliminates the inconsistencies common in static heating methods.

- If your primary focus is processing small batches or materials sensitive to mechanical stress: A static box furnace or a different type of specialized kiln may be a more practical and cost-effective solution.

Ultimately, understanding the core principle of controlled mixing and movement is the key to leveraging the power of a rotary furnace for your specific application.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Purpose | Uniform heating of loose or granular materials through continuous mixing and rotation. |

| Key Mechanism | Rotating tilted cylinder for constant tumbling and controlled material flow. |

| Ideal Applications | Roasting catalysts, processing powders, granular solids, and slurries on an industrial scale. |

| Main Advantages | High throughput, energy efficiency, and elimination of hot spots for consistent results. |

| Limitations | Not suitable for large objects or materials damaged by tumbling; higher mechanical complexity. |

Optimize your industrial thermal processing with KINTEK's advanced rotary furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnaces, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for uniform heating and high efficiency. Contact us today to discuss how our tailored solutions can enhance your production outcomes!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing