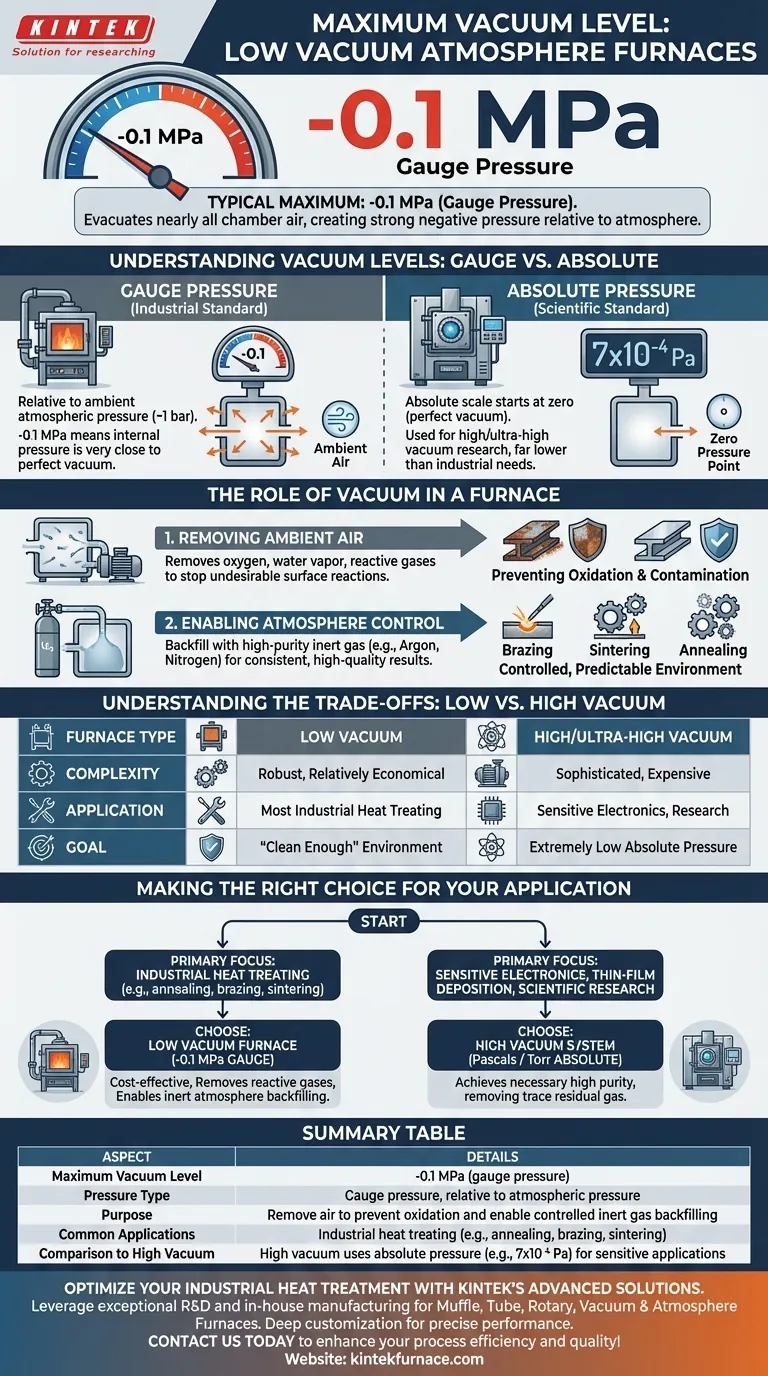

For a low vacuum atmosphere furnace, the typical maximum vacuum level you will see specified is -0.1 MPa (megapascals). This value represents the gauge pressure, meaning it is measured relative to the surrounding atmospheric pressure. It signifies that the furnace has evacuated nearly all of the air inside its chamber, creating a strong negative pressure differential compared to the outside.

The term "low vacuum" can be misleading. It does not imply a weak vacuum. Instead, it distinguishes a specific industrial range from the "high" or "ultra-high" vacuum levels used in scientific research, which are measured on an absolute scale and are orders of magnitude lower.

Understanding Vacuum Levels: Relative vs. Absolute

To make an informed decision, it's critical to understand how vacuum is measured. The specifications you encounter use two different reference points.

Gauge Pressure: The Industrial Standard

A gauge pressure reading of -0.1 MPa is common for industrial furnaces. This measurement is relative to the ambient atmospheric pressure (approximately 0.1 MPa or 1 bar at sea level).

Therefore, -0.1 MPa gauge pressure means the absolute pressure inside the furnace is very close to a perfect vacuum. It's a practical way of saying the furnace has removed as much atmosphere as mechanically possible within its design limits.

Absolute Pressure: The Scientific Standard

High vacuum furnaces are measured in absolute pressure units like Pascals (Pa). An absolute pressure scale starts at zero, which represents a perfect vacuum.

For comparison, a high vacuum furnace might operate at 7×10⁻⁴ Pa. This is an extremely low absolute pressure, far beyond what is required for most industrial heat-treating processes.

The Role of Vacuum in a Furnace

The primary purpose of creating a vacuum is not the vacuum itself, but the control of the atmosphere it enables. Removing the ambient air is the first step.

Preventing Oxidation and Contamination

By evacuating the chamber, you remove oxygen, water vapor, and other reactive gases. This prevents oxidation, decarburization, and other undesirable surface reactions on the workpiece during high-temperature processing.

Enabling Atmosphere Control

Once the chamber is evacuated, a specific, high-purity inert gas like argon or nitrogen can be backfilled. This creates a controlled, predictable environment for processes like brazing, sintering, or annealing, ensuring consistent and high-quality results.

Understanding the Trade-offs

Choosing between a low and high vacuum system involves significant trade-offs in complexity, cost, and application.

Low Vacuum Furnaces

These systems are robust, relatively economical, and sufficient for the vast majority of industrial heat treatment applications. Their goal is to create a "clean enough" environment to prevent negative reactions and allow for controlled gas backfilling.

High and Ultra-High Vacuum Furnaces

Achieving extremely low absolute pressures requires more sophisticated and expensive equipment. This includes multi-stage pump systems (e.g., turbo-molecular pumps backed by roughing pumps) and advanced chamber construction. These are necessary for sensitive applications like electronics manufacturing or fundamental materials research, where even trace amounts of residual gas can compromise the outcome.

Making the Right Choice for Your Application

Selecting the correct vacuum level depends entirely on your process requirements.

- If your primary focus is industrial heat treating (e.g., annealing, brazing, sintering): A low vacuum furnace rated to -0.1 MPa is the appropriate and cost-effective standard for removing reactive gases before backfilling with an inert atmosphere.

- If your primary focus is sensitive electronics, thin-film deposition, or scientific research: You must look at high vacuum systems specified in absolute pressure units (Pascals or Torr) to achieve the necessary purity.

Ultimately, a furnace's vacuum capability is a tool to achieve a specific atmospheric condition for your process.

Summary Table:

| Aspect | Details |

|---|---|

| Maximum Vacuum Level | -0.1 MPa (gauge pressure) |

| Pressure Type | Gauge pressure, relative to atmospheric pressure |

| Purpose | Remove air to prevent oxidation and enable controlled inert gas backfilling |

| Common Applications | Industrial heat treating (e.g., annealing, brazing, sintering) |

| Comparison to High Vacuum | High vacuum uses absolute pressure (e.g., 7×10⁻⁴ Pa) for sensitive applications like electronics |

Optimize your industrial heat treatment with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our strong deep customization capability ensures precise performance for applications like brazing and sintering. Contact us today to discuss how our furnaces can enhance your process efficiency and quality!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance