Proper maintenance of MPCVD equipment is the single most critical factor in ensuring consistent operation, extending the system's lifespan, and achieving the high-purity crystal growth it was designed for. Neglecting maintenance directly compromises the stability and reproducibility of the deposition process, leading to poor quality materials and costly downtime.

An MPCVD system is a precision instrument where the final product quality is a direct reflection of the process environment's integrity. Maintenance is not simply about preventing failure; it is the active management of the variables—purity, temperature, and pressure—that control the outcome of every growth cycle.

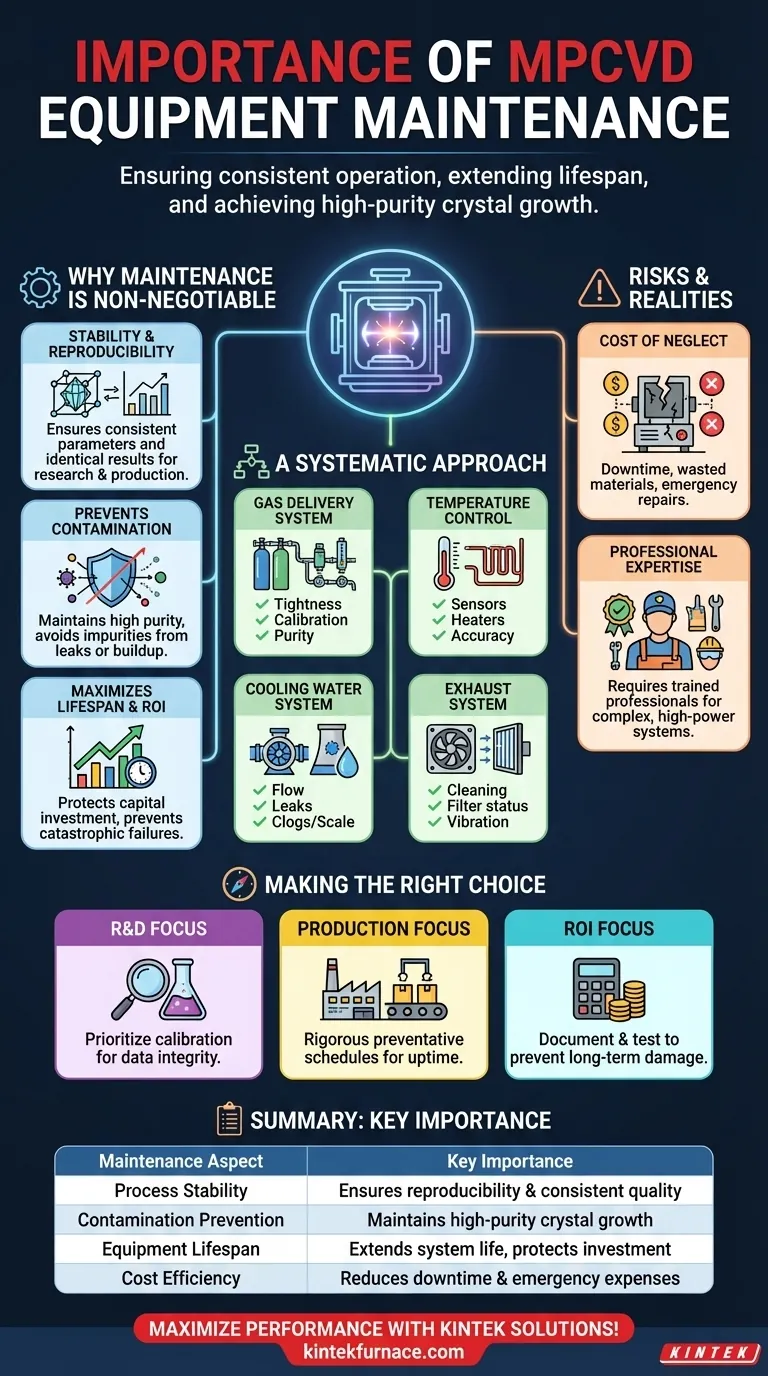

Why Maintenance is Non-Negotiable for Quality

An MPCVD (Microwave Plasma Chemical Vapor Deposition) system's primary advantage is its ability to produce high-quality materials with minimal contamination. A disciplined maintenance routine is what preserves this core capability.

Ensuring Process Stability and Reproducibility

The MPCVD method is valued for its stability, allowing for continuous deposition over long periods. Regular maintenance of systems like gas flow controllers and temperature sensors ensures that the parameters for one run are identical to the next.

This reproducibility is essential for both scientific research, where results must be comparable, and industrial production, where product consistency is paramount.

Preventing Contamination for High-Purity Materials

MPCVD systems are electrode-less, which is a key design feature to reduce contamination. However, this benefit is quickly negated by a poorly maintained system.

Leaks in gas lines or exhaust systems can introduce atmospheric impurities like nitrogen and oxygen. Internal buildup in the chamber or pipelines can also outgas and contaminate the crystal, undermining the entire purpose of the process.

Maximizing Equipment Lifespan and ROI

MPCVD equipment represents a significant capital investment. A proactive maintenance schedule protects this investment by preventing catastrophic failures.

Addressing minor issues like a clogged water line or a vibrating fan prevents them from cascading into major problems like a burned-out microwave generator or a failed vacuum pump, extending the operational life of the entire system.

A Systematic Approach to MPCVD Maintenance

Effective maintenance is not random; it is a systematic inspection and servicing of the core subsystems that enable the deposition process.

The Gas Delivery System

This system is the lifeline of the process, delivering the precise, pure gases required for crystal growth.

Regular checks must focus on the tightness of all pipelines to prevent leaks. Flow meters must be calibrated for accuracy, and gas purity must be consistently verified.

The Temperature Control System

Accurate temperature regulation is fundamental. The quality of the deposited material is highly sensitive to thermal fluctuations.

Heaters and temperature sensors must be inspected regularly to ensure they are functioning correctly. Inaccurate readings can lead to excessively high or low temperatures, directly impacting material quality.

The Cooling Water System

This system is the unsung hero of stability, removing excess heat from critical components like the microwave generator and the chamber walls.

Water pumps, cooling towers, and pipes must be checked for proper operation and leaks. Regular cleaning is vital to prevent clogs, corrosion, and scale buildup, which can severely restrict cooling efficiency.

The Exhaust System

The exhaust system safely removes byproduct gases and maintains the low pressure required for the plasma.

Ducts and filters must be cleaned of dust and process residue to maintain efficient filtration and flow. Fans should be monitored for unusual noise or vibration, which can signal impending failure.

Understanding the Risks and Realities

While essential, implementing a maintenance program has practical considerations that must be acknowledged.

The Cost of Neglect vs. The Cost of Maintenance

A comprehensive maintenance program requires time, resources, and potentially pausing production. However, this planned downtime is insignificant compared to the cost of unplanned failures.

The cost of neglect includes not only expensive emergency repairs but also wasted materials, missed deadlines, and a loss of confidence in the equipment's output.

The Requirement for Professional Expertise

MPCVD systems are complex integrated units combining high-power microwaves, high-voltage electricity, vacuum technology, and flammable gases.

Maintenance should only be performed by trained professionals. An operator lacking a deep understanding of the system's principles can easily cause expensive damage or create serious safety hazards.

Making the Right Choice for Your Goal

Your maintenance strategy should be aligned with your operational priorities.

- If your primary focus is research and development: Prioritize the regular calibration of gas flow meters and temperature sensors to ensure the absolute integrity and reproducibility of your experimental data.

- If your primary focus is high-volume production: Implement a rigorous, schedule-based preventative maintenance program for all mechanical systems (pumps, fans, cooling) to maximize uptime and predictable yield.

- If your primary focus is maximizing equipment ROI: Document every maintenance activity and regularly test cooling water quality to prevent silent killers like corrosion and scale, which cause the most expensive long-term damage.

Ultimately, a well-maintained MPCVD system transforms from a complex machine into a reliable and predictable manufacturing asset.

Summary Table:

| Maintenance Aspect | Key Importance |

|---|---|

| Process Stability | Ensures reproducibility and consistent material quality |

| Contamination Prevention | Maintains high-purity crystal growth by avoiding impurities |

| Equipment Lifespan | Extends system life and protects capital investment |

| Cost Efficiency | Reduces downtime and emergency repair expenses |

Maximize your MPCVD system's performance with KINTEK's expert solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace systems like CVD/PECVD, tailored to your unique needs. Our deep customization ensures precise experimental outcomes. Contact us today to discuss how we can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Why is maintaining gas pipelines important in MPCVD equipment? Ensure Purity and Safety in Crystal Growth

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth