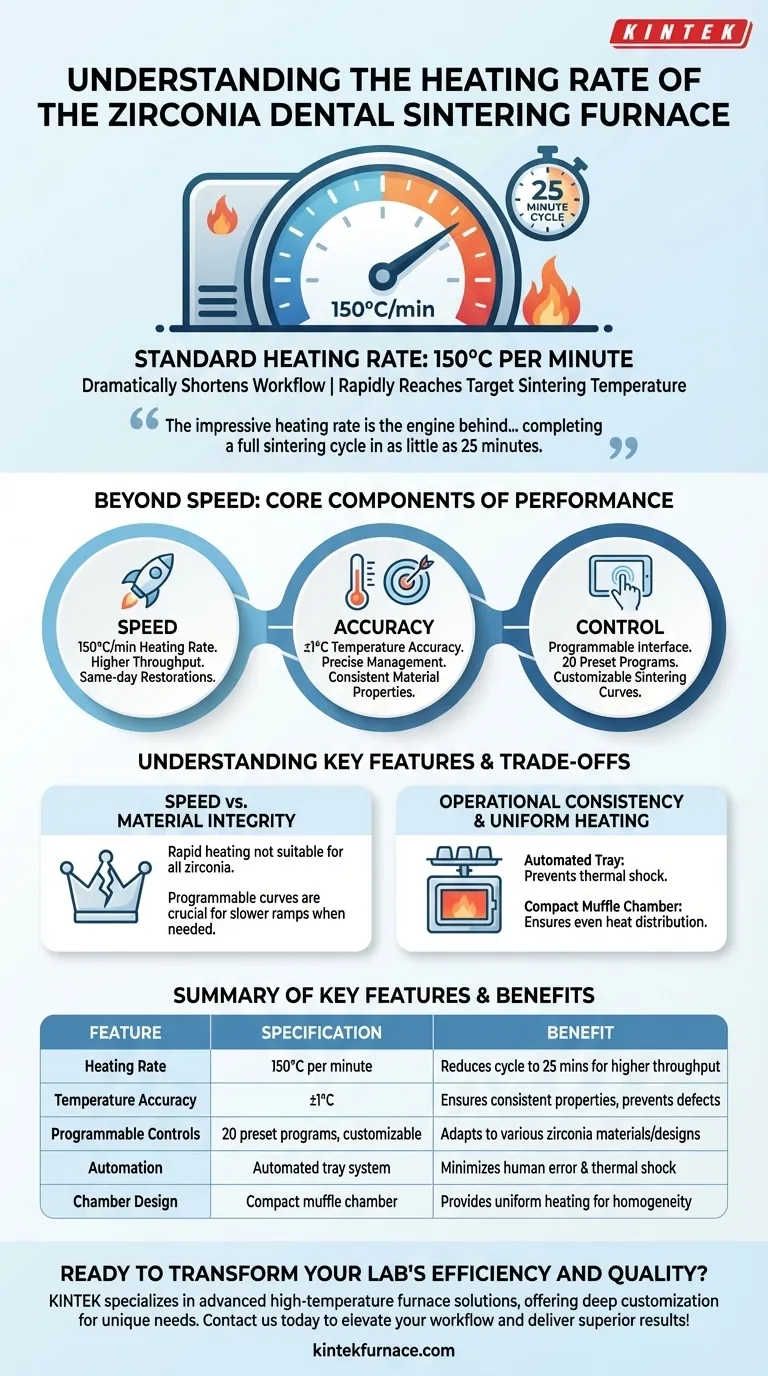

The standard heating rate for a high-performance Zirconia Dental Sintering Furnace is an exceptionally rapid 150°C per minute. This capability allows the furnace to reach its target sintering temperature in a fraction of the time required by conventional equipment. This speed is a cornerstone feature designed to dramatically shorten the entire restoration workflow.

The impressive heating rate is the engine behind the furnace's main benefit: completing a full sintering cycle in as little as 25 minutes. This speed, however, is only valuable because it is matched with precise temperature accuracy and programmable controls, which are essential for ensuring the final restoration's structural integrity and aesthetic quality.

Beyond Speed: The Core Components of Performance

A furnace's value is not defined by a single number. The heating rate is part of a system where speed, accuracy, and control must work in perfect harmony to produce reliable, high-quality dental restorations.

The Impact of a 150°C/min Heating Rate

The primary function of this rapid heating is to minimize furnace time. For a dental lab or clinic, this translates directly into higher throughput and the ability to offer same-day restorations.

By reaching sintering temperatures near 1530°C quickly, the overall process can be reduced to just 25 minutes, a significant improvement over traditional multi-hour cycles.

Why Accuracy is Non-Negotiable

A high heating rate is ineffective without precise temperature management. This furnace operates with a temperature accuracy of ±1°C.

This level of precision is critical. Uncontrolled or inaccurate heating, even with small deviations, can introduce internal stresses, micro-fractures, or inconsistent translucency in the final zirconia crown or bridge.

Accuracy ensures that the material properties specified by the zirconia manufacturer are achieved consistently, leading to predictable strength and aesthetics.

The Power of Programmable Control

The furnace's capabilities are managed through an intuitive touch screen interface with built-in programming.

With features like 20 preset heating programs, operators can quickly select a validated cycle. More importantly, they can fine-tune or create custom sintering curves to match the specific requirements of different zirconia materials or complex restoration designs.

This programmability gives the user full control, allowing them to balance the need for speed with the specific demands of the material.

Understanding the Trade-offs and Key Features

While speed is a major selling point, a technical understanding requires looking at the potential compromises and the features designed to mitigate them.

Speed vs. Material Integrity

The central trade-off is speed versus the potential for thermal shock. Not all zirconia materials are designed to withstand a 150°C per minute heating ramp.

Using such a rapid cycle on an unsuitable material can compromise the final restoration. This is why the programmable curve settings are so crucial—they allow the technician to use a slower, gentler heating rate when required by the material manufacturer.

Operational Consistency and Automation

Human error can undermine even the most advanced equipment. Features like an automated tray that moves the restoration in and out of the hot zone are not just for convenience.

This automation ensures a smooth, controlled temperature transition, preventing the thermal shock that can occur from opening a hot furnace door or manually handling the tray. It is a key feature for ensuring repeatable, high-quality outcomes.

Chamber Design for Uniform Heating

The furnace utilizes a compact muffle chamber. The design of this chamber is engineered to ensure that heat is distributed evenly and rapidly.

Uniform heating is essential for preventing hot or cold spots within the chamber, which could cause different parts of the same restoration to sinter inconsistently. This ensures a homogenous final product.

Making the Right Choice for Your Goal

To leverage this technology effectively, align its features with your primary operational objective.

- If your primary focus is maximum throughput and same-day restorations: The 150°C/min heating rate and the 25-minute total cycle time are your most critical features for achieving chair-side efficiency.

- If your primary focus is material versatility and aesthetic results: The ability to create and customize sintering curves is more important than raw speed, allowing you to perfect outcomes for various zirconia brands.

- If your primary focus is minimizing remakes and ensuring consistency: The combination of ±1°C temperature accuracy and automated tray handling will be key to producing predictable, high-quality results every time.

Ultimately, understanding how the furnace's heating rate, accuracy, and control systems work together is the key to unlocking both speed and uncompromising quality in your restorations.

Summary Table:

| Feature | Specification | Benefit |

|---|---|---|

| Heating Rate | 150°C per minute | Reduces sintering cycle to as little as 25 minutes for higher throughput |

| Temperature Accuracy | ±1°C | Ensures consistent material properties, preventing defects |

| Programmable Controls | 20 preset programs, customizable curves | Allows adaptation to various zirconia materials and designs |

| Automation | Automated tray system | Minimizes human error and thermal shock for reliable results |

| Chamber Design | Compact muffle chamber | Provides uniform heating for homogenous restorations |

Ready to transform your dental lab's efficiency and quality? KINTEK specializes in advanced high-temperature furnace solutions, including our precision Zirconia Dental Sintering Furnaces. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs—whether you're focused on same-day restorations, material versatility, or consistency. Our product line, featuring Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, ensures you get the perfect fit for your laboratory. Contact us today to discuss how our solutions can elevate your workflow and deliver superior results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations