The future outlook for Microwave Plasma Chemical Vapor Deposition (MPCVD) in diamond synthesis is exceptionally strong. This method has established itself as the premier technology for creating high-quality, lab-grown diamonds due to its unmatched precision, purity, and scalability. Its ability to produce large, single-crystal diamonds with tailored properties is driving innovation across electronics, optics, and other advanced industries.

MPCVD is not merely an incremental improvement; it represents a fundamental shift in diamond production. The technology's core advantage lies in its ability to create a highly controlled, contamination-free environment, enabling the growth of large, flawless diamonds at speeds and costs that are making previously theoretical applications commercially viable.

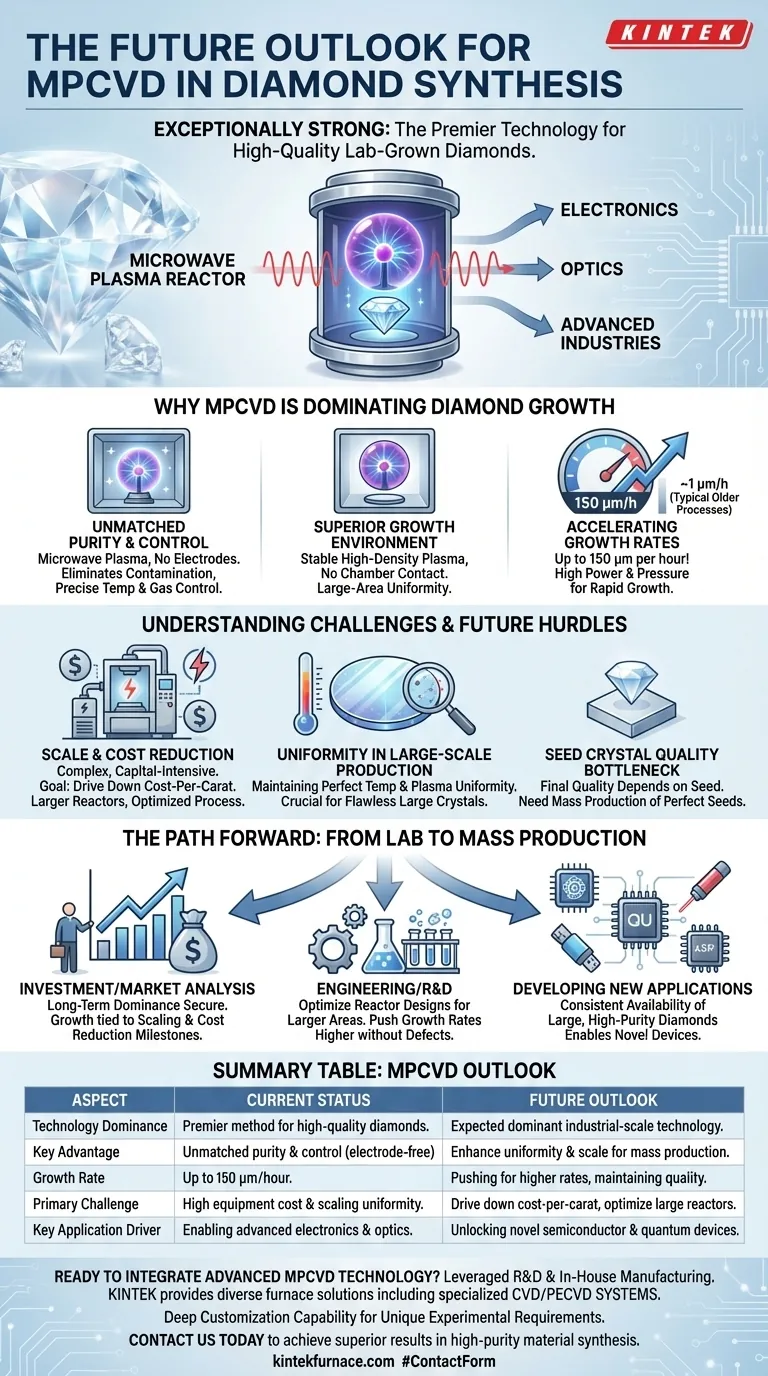

Why MPCVD is Dominating Diamond Growth

The dominance of MPCVD stems from fundamental technical advantages that overcome the limitations of older methods like Hot Filament CVD (HFCVD) or Direct Current Plasma Jet CVD (DC-PJ CVD).

Unmatched Purity and Control

MPCVD reactors use microwaves to generate a plasma, completely avoiding the hot filaments or electrodes used in other methods. This design eliminates a primary source of contamination, resulting in diamonds of exceptionally high purity.

Furthermore, the process allows for precise, stable temperature control and the flexible use of various gases. This level of control is critical for tailoring the diamond's properties for specific, high-stakes applications.

A Superior Growth Environment

The microwave-generated plasma is contained in a stable, high-density ball that does not contact the chamber walls. This prevents the diamond film from being contaminated by the vessel itself, ensuring a cleaner final product.

This stable plasma can be generated over a large area, which is essential for growing large-diameter diamond wafers and ensuring uniform quality across the entire surface.

Accelerating Growth Rates and Efficiency

Modern MPCVD systems can achieve growth rates up to 150 μm per hour, a dramatic increase over the ~1 μm per hour typical of older polycrystalline processes.

This acceleration is achieved by increasing the microwave power and chamber pressure. These adjustments enhance the decomposition of the reaction gases, creating a higher concentration of active carbon species that fuel rapid diamond growth.

Understanding the Challenges and Future Hurdles

While MPCVD is the most promising path forward, its industrial-scale implementation is not without challenges. Understanding these hurdles is key to appreciating the focus of current research and development.

The Pursuit of Scale and Cost Reduction

MPCVD reactors are complex, capital-intensive pieces of equipment that consume significant energy. While cost-effective relative to the quality produced, the primary goal for mass production is to continue driving down the cost-per-carat.

This involves designing larger, more efficient reactors and optimizing process parameters to maximize throughput without compromising the diamond's quality.

Uniformity in Large-Scale Production

As the size of the diamond crystal increases, maintaining perfect temperature and plasma uniformity across its entire surface becomes exponentially more difficult.

Any slight variation can introduce stress or defects into the crystal lattice. A major focus of ongoing engineering is the refinement of reactor geometry and plasma control systems to ensure flawless growth at ever-larger sizes.

Seed Crystal Quality as a Bottleneck

The MPCVD process grows a diamond on top of a small, pre-existing "seed" crystal. The quality and purity of this initial seed directly dictate the quality of the final, much larger diamond.

Therefore, improving the methods for producing large quantities of perfect seed crystals is a critical dependency for scaling the entire MPCVD production chain.

The Path Forward: From Lab to Mass Production

The trajectory for MPCVD is clear: it is moving from a specialized laboratory technique to the foundational technology for an industrial-scale engineered materials market.

- If your primary focus is investment or market analysis: MPCVD's technical superiority secures its long-term dominance, with future growth directly tied to successful scaling and cost-reduction milestones.

- If your primary focus is engineering or R&D: The next frontiers are optimizing reactor designs for larger growth areas and refining process controls to push growth rates higher without introducing defects.

- If your primary focus is developing new applications: The consistent availability of large, high-purity single-crystal diamonds from MPCVD is the key enabler for creating novel semiconductor, optical, and quantum devices.

Ultimately, MPCVD is the technology that transitions diamond from a rare, natural gem to a high-performance engineered material, with its full potential just beginning to be realized.

Summary Table:

| Aspect | Current Status | Future Outlook |

|---|---|---|

| Technology Dominance | Premier method for high-quality diamonds | Expected to remain the dominant industrial-scale technology |

| Key Advantage | Unmatched purity and control via electrode-free plasma | Focus on enhancing uniformity and scaling for mass production |

| Growth Rate | Up to 150 μm/hour | Pushing for higher rates while maintaining quality |

| Primary Challenge | High equipment cost and scaling uniformity | Driving down cost-per-carat and optimizing large-area reactors |

| Key Application Driver | Enabling advanced electronics and optics | Unlocking novel semiconductor and quantum devices |

Ready to Integrate Advanced MPCVD Technology into Your Lab?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including specialized CVD/PECVD Systems.

Our strong deep customization capability allows us to precisely meet your unique experimental requirements for diamond synthesis and other advanced materials.

Contact us today to discuss how our expertise can help you achieve superior results in high-purity material synthesis.

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does the MPCVD process work to deposit diamond? A Guide to High-Purity Synthesis

- What does CVD stand for and what is its primary function? Discover High-Purity Thin Film Deposition

- What are the key features of MPCVD single crystal diamond deposition equipment? Precision Control for High-Quality Growth

- Can the reducing atmosphere be replaced with other gaseous mediums? Explore Advanced Surface Engineering Solutions

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance