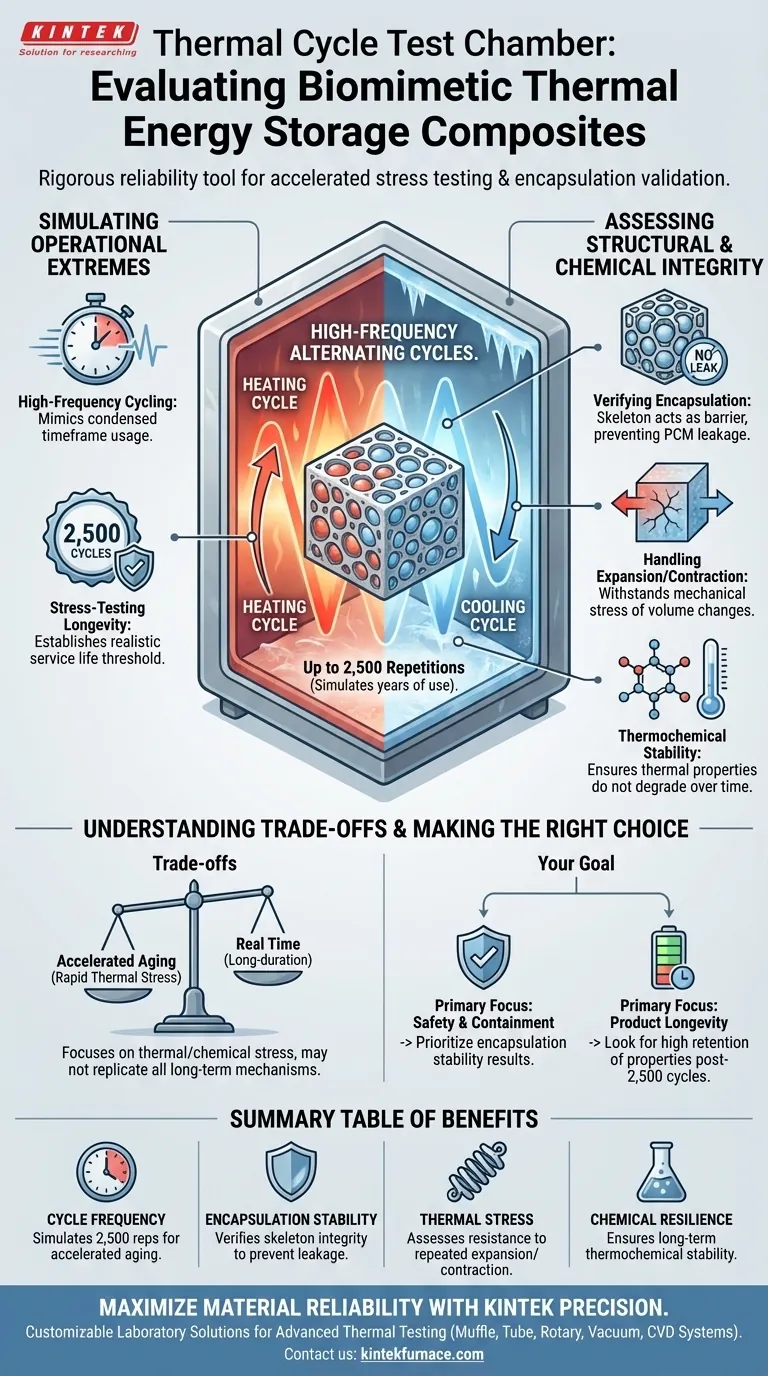

A thermal cycle test chamber functions as a rigourous reliability tool designed to evaluate the durability and performance of biomimetic thermal energy storage composites under accelerated stress. By subjecting these materials to high-frequency alternating heating and cooling cycles—often reaching up to 2,500 repetitions—the chamber simulates extreme working conditions to verify the material's physical and chemical integrity.

The core purpose of this testing is to validate the encapsulation stability of the biomimetic porous skeleton, ensuring it can effectively prevent Phase Change Material (PCM) leakage during repeated thermal expansion and contraction.

Simulating Operational Extremes

High-Frequency Cycling

The test chamber does not merely warm the material; it enforces rapid, alternating cycles of heating and cooling. This high-frequency oscillation is designed to mimic years of usage in a condensed timeframe.

Stress-Testing Longevity

Standard tests often run up to 2,500 cycles. This high volume of repetition is critical for establishing a realistic service life for the material.

If a composite can survive this threshold, it demonstrates the robustness required for real-world energy storage applications.

Assessing Structural and Chemical Integrity

Verifying Encapsulation Capability

The primary mechanical challenge for these composites is keeping the Phase Change Material (PCM) contained.

The test directly reflects the ability of the biomimetic porous skeleton to act as a barrier. It confirms whether the structure can prevent PCM leakage when the material becomes liquid during heat absorption.

Handling Expansion and Contraction

As PCMs cycle between solid and liquid states, they undergo significant volume changes.

The thermal cycle test assesses if the composite skeleton can withstand the mechanical stress of this repeated expansion and contraction without cracking or deforming.

Thermochemical Stability

Beyond physical structure, the test evaluates the chemical resilience of the material.

It ensures that the material's thermal properties do not degrade over time, confirming that the composite remains chemically stable throughout its intended service life.

Understanding the Trade-offs

Accelerated Aging vs. Real Time

While 2,500 cycles provide a strong indicator of lifespan, it is an accelerated simulation.

Rapid cycling stresses the material thermally but may not perfectly replicate low-frequency, long-duration degradation mechanisms found in decades-long applications.

Focus on Thermal Stress

This specific test isolates thermal expansion and chemical stability.

It is highly effective for testing leakage and breakdown, but it does not necessarily account for other external mechanical forces or environmental corrosion unless combined with other testing protocols.

Making the Right Choice for Your Goal

To effectively utilize data from a thermal cycle test, align the results with your specific engineering requirements.

- If your primary focus is Safety and Containment: Prioritize the encapsulation stability results to ensure the porous skeleton prevents all PCM leakage under stress.

- If your primary focus is Product Longevity: Look for high retention of thermochemical properties after the full 2,500-cycle threshold to guarantee a long service life.

By validating the biomimetic structure through rigorous thermal cycling, you ensure the composite will deliver consistent, leak-free performance in demanding energy storage applications.

Summary Table:

| Feature | Testing Benefit |

|---|---|

| Cycle Frequency | Simulates up to 2,500 repetitions for accelerated aging |

| Encapsulation Stability | Verifies porous skeleton integrity to prevent PCM leakage |

| Thermal Stress | Assesses resistance to repeated expansion and contraction |

| Chemical Resilience | Ensures long-term thermochemical stability without degradation |

Maximize Material Reliability with KINTEK Precision

Ensure your biomimetic composites meet the highest standards of durability and thermal efficiency. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of customizable laboratory solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—tailored to the rigorous demands of advanced thermal testing.

Ready to elevate your research and prevent material failure? Contact KINTEK today to discuss how our high-temperature furnace systems can be customized to your unique energy storage applications.

Visual Guide

References

- Min Yu, Dou Zhang. Review of Bioinspired Composites for Thermal Energy Storage: Preparation, Microstructures and Properties. DOI: 10.3390/jcs9010041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- How is a muffle furnace utilized in environmental analysis? Essential for Precise Organic and Inorganic Composition Testing

- How does a laboratory box furnace contribute to the temperature program control for synthesizing PrVSb3 single crystals?

- Why are muffle furnaces important in laboratories? Essential for Contamination-Free High-Temperature Processing

- What are the industrial uses of a muffle furnace? Enhance Precision and Purity in High-Temp Applications

- What are the primary applications of muffle furnaces in laboratory settings? Unlock Precision in Material Analysis and Synthesis

- What role does a muffle furnace play in the pretreatment of calcium carbonate? Ensure Accurate Thermal Studies

- What is the primary function of a laboratory resistance furnace in Al-Li alloy prep? Achieve Optimal Smelting Quality

- What is the mechanism of a high-temperature furnace in Bi-2223 sintering? Achieve Precision Phase Transformation