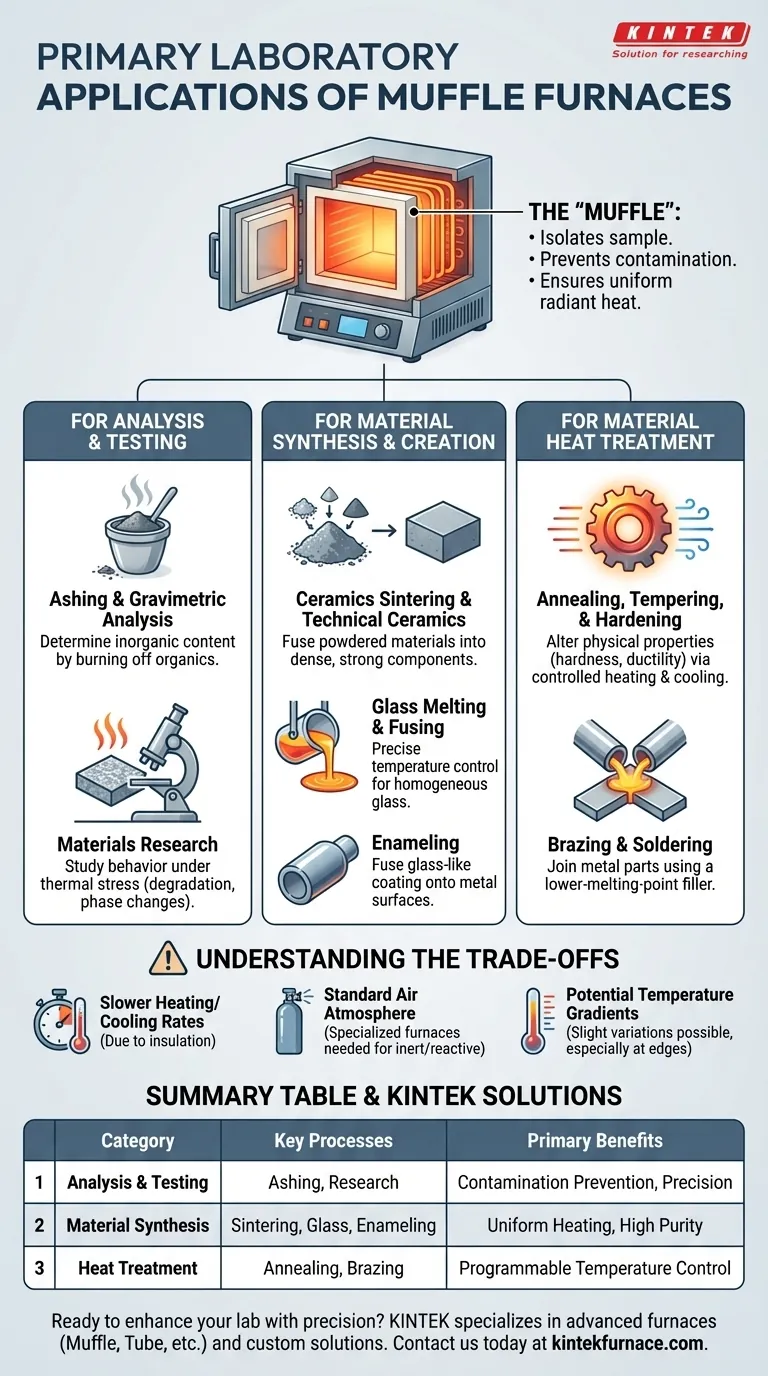

At its core, a muffle furnace is a high-temperature oven used for processes that demand thermal precision and purity. Its primary applications in a laboratory fall into three main categories: analyzing the composition of materials through decomposition, creating new materials or coatings, and modifying the physical properties of existing materials through controlled heat treatment.

A muffle furnace's value isn't just its high heat, but its unique design. The internal chamber, or 'muffle,' isolates the sample from the heating elements. This design prevents contamination and ensures highly uniform radiant heat, making it indispensable for any process where material purity and precise thermal transformation are critical.

The Principle: Why Isolation and Uniformity Matter

A muffle furnace's capabilities stem directly from its construction. Understanding this principle is key to knowing when to use it.

What is a "Muffle"?

The "muffle" is the furnace's inner chamber, typically made of high-temperature ceramic. It separates the material being heated from the actual heating elements and any potential byproducts of combustion in fuel-fired models.

Preventing Contamination

By isolating the sample, the muffle ensures that impurities from the heating source do not affect the sample's chemistry. This is crucial for analytical procedures and for creating high-purity materials like technical ceramics or glass.

Ensuring Uniform Heating

The muffle heats up and then radiates that heat evenly from all sides onto the sample. This eliminates hot spots and creates a highly stable, uniform thermal environment essential for repeatable experiments and consistent material properties.

Core Applications in Detail

The combination of high heat, purity, and uniformity makes the muffle furnace a versatile tool for specific scientific and industrial tasks.

For Analysis and Testing

This category focuses on using heat to decompose a material to understand its composition or behavior.

Ashing and Gravimetric Analysis

This is one of the most common laboratory uses. A sample, such as a polymer, food product, or coal, is heated to a high temperature to completely burn off all organic and volatile components. The remaining non-combustible material, or ash, is then weighed to determine the inorganic content.

Materials Research

Scientists use muffle furnaces to study how materials behave under extreme thermal stress. This includes testing for thermal degradation, stability, and phase changes at high temperatures.

For Material Synthesis and Creation

Here, the furnace is used to create new materials or apply coatings that require clean, precise heat.

Glass Melting and Fusing

Creating homogenous glass requires precise temperature control to achieve the desired viscosity without introducing imperfections. The clean environment of a muffle furnace is ideal for this process.

Technical Ceramics and Sintering

Sintering is a process where powdered materials, like ceramics or metals, are heated below their melting point until their particles fuse into a solid, dense piece. The uniform heat of a muffle furnace is critical for creating strong, consistent ceramic components.

Enameling

Enameling involves fusing a glass-like coating onto a metal surface. The furnace provides the clean, consistent heat needed for the enamel to melt, flow, and bond to the substrate without defects.

For Material Heat Treatment

This involves altering the microstructure of a material, most often a metal, to change its physical properties like hardness or ductility.

Annealing, Tempering, and Hardening

These processes involve heating a metal to a specific temperature, holding it there for a set time (soaking), and then cooling it at a controlled rate. A muffle furnace with a programmable controller provides the precision needed for these metallurgical transformations on small components.

Brazing and Soldering

These techniques join metal parts using a filler metal that has a lower melting point. A muffle furnace can provide the controlled, uniform heat needed to melt the filler metal evenly across a joint.

Understanding the Trade-offs

While powerful, a muffle furnace is not always the right tool. Its design comes with inherent limitations.

Slower Heating and Cooling Rates

The same ceramic muffle that ensures thermal stability also acts as a significant insulator. This means muffle furnaces generally take longer to heat up and cool down compared to direct-fired kilns or ovens.

Atmosphere is a Factor

A standard muffle furnace operates with a normal air atmosphere. If your process requires an inert atmosphere (like nitrogen or argon) or a reactive one, you will need a specialized, often more expensive, furnace designed for atmosphere control.

Potential Temperature Gradients

While far more uniform than other heating methods, a slight temperature gradient can still exist between the center of the chamber and the areas closer to the walls. For extremely sensitive processes, this must be taken into account.

Making the Right Choice for Your Goal

To determine if a muffle furnace is right for your work, match your primary objective to its core strengths.

- If your primary focus is quantitative analysis (like ashing): You need the repeatable, controlled, and clean combustion environment a muffle furnace provides to get accurate results.

- If your primary focus is material creation (ceramics, glass): You need the furnace's uniform, radiant heat and contaminant-free chamber to prevent defects and ensure structural integrity.

- If your primary focus is modifying metal properties (heat treating): You need a furnace with the programmable temperature control necessary for precise ramps, soaks, and cooling cycles.

Ultimately, selecting a muffle furnace means prioritizing thermal precision and material purity for your high-temperature work.

Summary Table:

| Application Category | Key Processes | Primary Benefits |

|---|---|---|

| Analysis and Testing | Ashing, Gravimetric Analysis, Materials Research | Contamination prevention, precise thermal control |

| Material Synthesis | Glass Melting, Ceramics Sintering, Enameling | Uniform heating, high purity for defect-free creation |

| Heat Treatment | Annealing, Tempering, Hardening, Brazing | Programmable temperature for property modification |

Ready to enhance your lab's capabilities with precision high-temperature solutions? KINTEK specializes in advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring purity, uniformity, and efficiency. Contact us today to discuss how our tailored furnace solutions can drive your research forward!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment