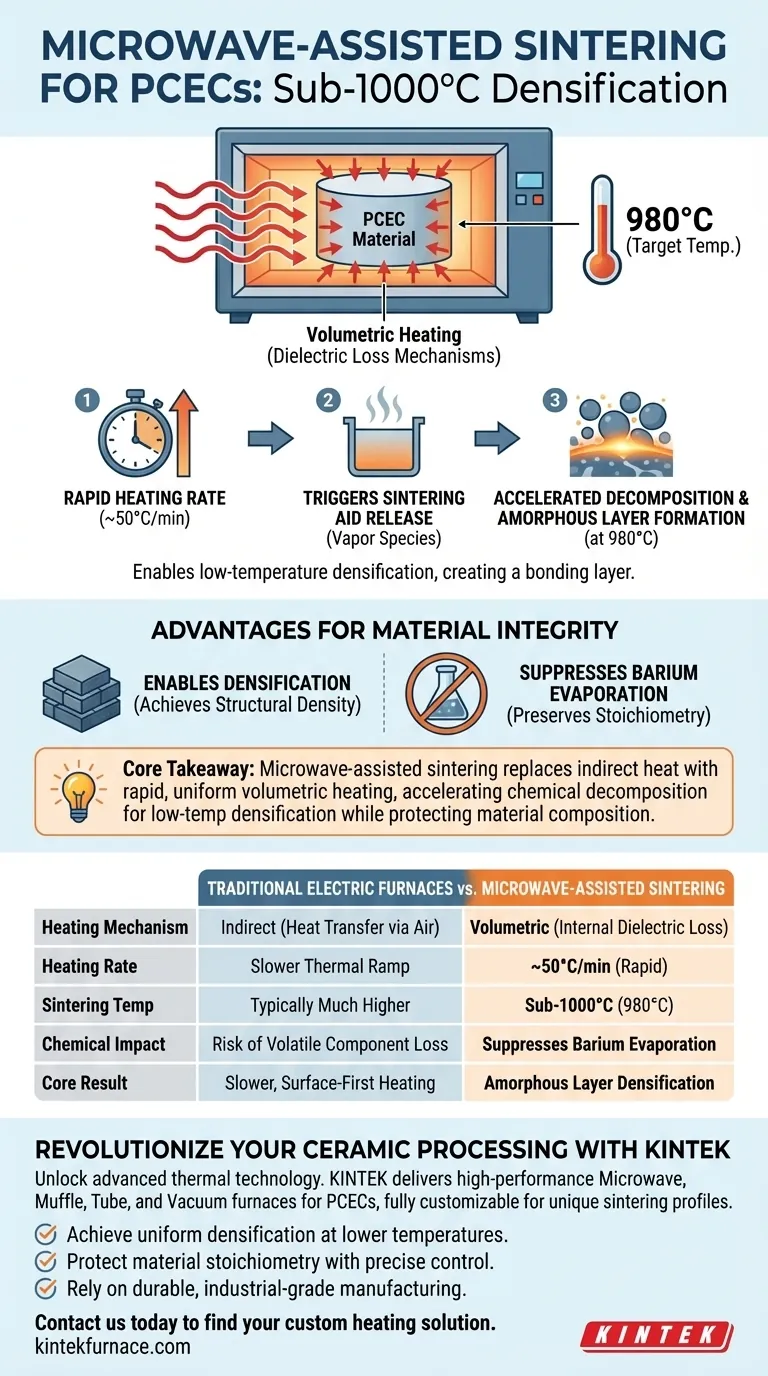

The primary function of a microwave-assisted sintering furnace is to utilize dielectric loss mechanisms to achieve volumetric heating, allowing the material to heat simultaneously from the inside out. By sustaining a high heating rate of approximately 50 °C/min, this technology triggers the release of vapor species from a sintering aid reservoir, facilitating successful densification at a significantly reduced temperature of 980 °C.

Core Takeaway Microwave-assisted sintering fundamentally alters the thermal processing of ceramics by replacing indirect heat transfer with rapid, uniform volumetric heating. This specific thermal environment accelerates the chemical decomposition necessary to form an amorphous bonding layer, enabling low-temperature densification while simultaneously preserving material composition by suppressing barium evaporation.

The Mechanism of Low-Temperature Sintering

Utilizing Volumetric Heating

Unlike traditional electric furnaces that rely on indirect heat transfer (heating the air around the sample), a microwave-assisted furnace employs dielectric loss mechanisms.

This allows for volumetric heating, where the energy is absorbed directly within the volume of the sample. The result is a much more uniform thermal field throughout the ceramic material.

Triggering the Sintering Aid

The furnace is capable of achieving a high heating rate of roughly 50 °C/min.

This rapid increase in temperature is critical for the process. It quickly triggers the sintering aid reservoir to release necessary vapor species, a step that might be delayed or uneven in slower heating environments.

Accelerating Chemical Decomposition

The uniform and rapid thermal field provided by the microwave furnace specifically accelerates the decomposition of BYN.

This decomposition induces the formation of an amorphous layer on the electrolyte surface. Critically, this reaction occurs at the relatively low temperature of 980 °C, setting the stage for material binding without excessive heat.

Advantages for Material Integrity

Enabling Densification

The formation of the amorphous layer mentioned above is the key driver for material densification.

By achieving this state at sub-1000 °C temperatures, the furnace ensures the PCECs achieve the required structural density. This overcomes the energy barriers usually associated with sintering these complex ceramics.

Suppressing Barium Evaporation

High-temperature sintering often leads to the degradation of volatile components.

By capping the process at 980 °C through microwave assistance, the system suppresses barium evaporation. This ensures the chemical stoichiometry of the final product remains intact, which is vital for the electrochemical performance of the cell.

Understanding the Operational Differences

The Limitation of Indirect Heating

It is important to recognize why traditional methods often fail to achieve similar results at these temperatures.

Traditional electric furnaces utilize indirect heat transfer, which typically results in slower heating rates. This slower thermal ramp often fails to trigger the rapid BYN decomposition required to form the amorphous layer at lower temperatures.

The Necessity of Rate Control

The success of this method is heavily dependent on the specific heating rate capabilities of the equipment.

The approximately 50 °C/min heating rate is not just for speed; it is a functional requirement to synchronize the vapor release and chemical decomposition. Deviating from this rapid rate could compromise the formation of the densifying amorphous layer.

Making the Right Choice for Your Goal

To determine if microwave-assisted sintering is the correct approach for your fabrication process, consider your specific material constraints.

- If your primary focus is Material Composition: This method is superior for preventing volatile loss, specifically the suppression of barium evaporation during processing.

- If your primary focus is Processing Speed: The 50 °C/min heating rate offers a rapid processing cycle that traditional indirect furnaces cannot match while maintaining uniformity.

- If your primary focus is Energy Efficiency: Lowering the sintering temperature to 980 °C significantly reduces the thermal budget required compared to standard high-temperature protocols.

Microwave-assisted sintering transforms the fabrication of PCECs by leveraging rapid volumetric heating to achieve dense, chemically stable electrolytes at temperatures previously thought insufficient.

Summary Table:

| Feature | Microwave-Assisted Sintering | Traditional Electric Furnaces |

|---|---|---|

| Heating Mechanism | Volumetric (Internal Dielectric Loss) | Indirect (Heat Transfer via Air) |

| Heating Rate | ~50 °C/min (Rapid) | Slower Thermal Ramp |

| Sintering Temp | Sub-1000 °C (Target: 980 °C) | Typically Much Higher |

| Chemical Impact | Suppresses Barium Evaporation | Risk of Volatile Component Loss |

| Core Result | Amorphous Layer Densification | Slower, Surface-First Heating |

Revolutionize Your Ceramic Processing with KINTEK

Unlock the power of advanced thermal technology for your laboratory. KINTEK delivers high-performance Microwave, Muffle, Tube, and Vacuum furnaces specifically engineered to handle the delicate requirements of Protonic Ceramic Electrochemical Cells (PCECs). Our systems are backed by expert R&D and are fully customizable to meet your unique sintering profiles and heating rate needs.

Why choose KINTEK?

- Achieve uniform densification at lower temperatures.

- Protect material stoichiometry with precise atmospheric and thermal control.

- Rely on durable, industrial-grade manufacturing for consistent research results.

Ready to optimize your material integrity? Contact us today to find your custom heating solution.

Visual Guide

References

- Dongyeon Kim, Kang Taek Lee. Sub‐1000 °C Sintering of Protonic Ceramic Electrochemical Cells via Microwave‐Driven Vapor Phase Diffusion. DOI: 10.1002/adma.202506905

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the advantages of using a laboratory vacuum drying oven for WS2 nanoparticles? Optimize Purity and Structure

- Why is prolonged treatment in a vacuum drying oven necessary for SnO2-based anodes? Ensure Reliable Electrochemical Data

- What types of materials and processes are compatible with vacuum furnaces? Achieve Purity and Precision in Heat Treatment

- What industries benefit from using vacuum furnaces? Achieve Purity and Precision in High-Stakes Sectors

- What are the chamber specifications of the vacuum furnace system? Ensure Purity and Safety in High-Temp Processing

- What are the common heating methods used in vacuum furnaces? Choose the Best for Your Materials

- What role do vacuum systems play in chemical processes? Master Precision Control for Gas-Sensitive Reactions

- What is the purpose of vacuum sintering furnaces? Achieve High-Purity, Dense Materials