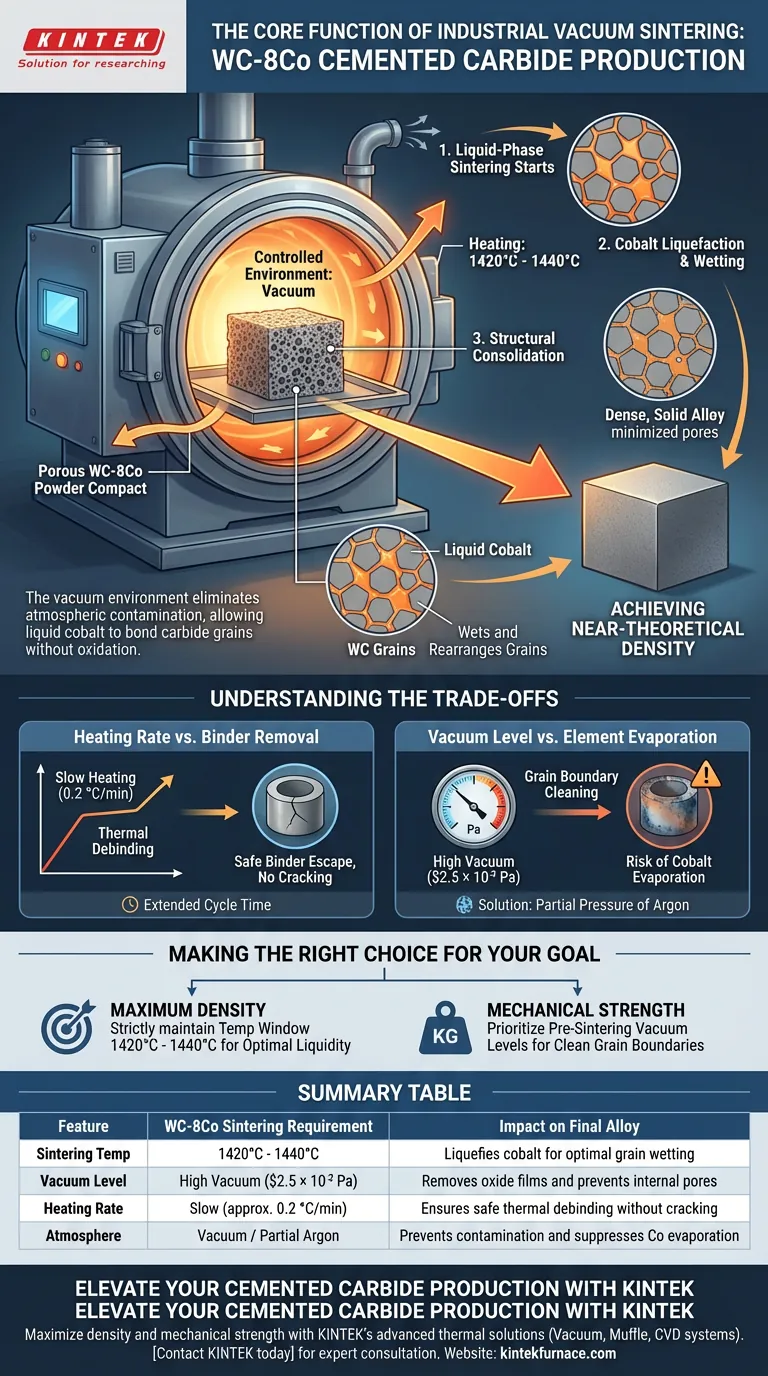

The core function of an industrial vacuum sintering furnace in the production of WC-8Co cemented carbide is to create a controlled environment that drives liquid-phase sintering. By heating the material to between 1420°C and 1440°C under a vacuum, the furnace liquefies the cobalt binder, allowing it to thoroughly wet the tungsten carbide grains. This process effectively removes oxide films and gases, ensuring the final alloy achieves a densification level close to its theoretical limit.

By eliminating atmospheric contamination and enabling precise thermal control, the furnace transforms a porous powder compact into a dense, solid alloy. The vacuum environment is the key variable that allows the cobalt binder to flow freely and bond the carbide grains without the interference of oxidation.

Achieving Near-Theoretical Density

The Mechanism of Liquid-Phase Sintering

The furnace operates at a specific temperature range, typically 1420–1440°C for WC-8Co mixtures. At these temperatures, the cobalt phase transitions from solid to liquid.

Capillary Action and Wetting

Once liquefied, the cobalt does not merely sit between the tungsten carbide (WC) particles; it actively wets the grains. Capillary forces pull the WC particles closer together, filling the voids that existed in the powder form.

Structural Consolidation

This rearrangement of particles is what drives densification. The furnace maintains this temperature to ensure the material creates a continuous, solid structure, eliminating the porosity inherent in the raw powder compact.

The Critical Role of the Vacuum Environment

Removing Oxide Films

Before the cobalt can successfully wet the tungsten carbide, the surface of the powder must be pristine. The vacuum environment strips away oxide films from the powder surfaces that would otherwise act as a barrier to bonding.

Eliminating Adsorbed Gases

Raw powders often contain adsorbed gases that can become trapped inside the material during heating. The vacuum effectively extracts these volatile impurities and gases.

Preventing Pore Formation

By removing these gases before the material seals itself, the furnace prevents the formation of internal pores. This ensures the final sintered body is solid and meets the mechanical property requirements of the design.

Understanding the Trade-offs

Heating Rate vs. Binder Removal

A standard vacuum sintering cycle often utilizes a slow heating rate (e.g., 0.2 °C/min) during the initial stages. This is necessary for thermal debinding, allowing residual binders to escape gently without cracking the part. However, this extends the total cycle time significantly compared to rapid techniques like induction heating.

Vacuum Level vs. Element Evaporation

While a high vacuum (e.g., $2.5 \times 10^{-2}$ Pa) is essential for cleaning grain boundaries, extreme vacuum conditions at peak temperatures can potentially lead to the evaporation of the cobalt binder itself. The process requires a balance, sometimes introducing a partial pressure of argon to suppress evaporation while maintaining protection.

Making the Right Choice for Your Goal

To maximize the performance of your WC-8Co production, align your furnace operation with your specific quality metrics.

- If your primary focus is Maximum Density: Strictly maintain the temperature window between 1420°C and 1440°C to ensure optimal liquidity of the cobalt phase without inducing excessive grain growth.

- If your primary focus is Mechanical Strength: Prioritize the pre-sintering vacuum levels to ensure the complete removal of oxide films and adsorbed gases, creating cleaner grain boundaries.

The ultimate value of the vacuum sintering furnace lies in its ability to synchronize high heat with a contaminant-free environment, turning raw powder into a high-performance industrial tool.

Summary Table:

| Feature | WC-8Co Sintering Requirement | Impact on Final Alloy |

|---|---|---|

| Sintering Temp | 1420°C - 1440°C | Liquefies cobalt for optimal grain wetting |

| Vacuum Level | High Vacuum ($2.5 \times 10^{-2}$ Pa) | Removes oxide films and prevents internal pores |

| Heating Rate | Slow (approx. 0.2 °C/min) | Ensures safe thermal debinding without cracking |

| Atmosphere | Vacuum / Partial Argon | Prevents contamination and suppresses Co evaporation |

Elevate Your Cemented Carbide Production with KINTEK

Maximize the density and mechanical strength of your WC-8Co alloys with KINTEK’s advanced thermal solutions. Backed by expert R&D and precision manufacturing, we provide high-performance Vacuum, Muffle, and CVD systems tailored for the rigorous demands of liquid-phase sintering. Whether you need customizable furnace parameters to prevent element evaporation or specialized heating cycles for structural consolidation, our systems ensure your materials meet their theoretical limits.

Ready to optimize your sintering process? Contact KINTEK today to consult with our experts on your unique lab or industrial high-temperature needs.

Visual Guide

References

- Vitalii A. Sheremet. Effect of Cold Isostatic Pressing and VC Grain Growth Inhibitor Addition on WC Grain Size and Mechanical Properties of WC-8Co Cemented Carbide. DOI: 10.24191/jmeche.v21i2.26252

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the significance of using a vacuum drying oven for silicon electrode slurries? Achieve Robust Battery Integrity

- What are the advantages of using a vacuum drying oven for ceramic powders? Preserve Purity and Sinterability

- What are the primary functions of a vacuum furnace? Achieve Superior Material Processing in a Controlled Environment

- How does vacuum heat treating affect the grain structure of metal alloys? Achieve Precise Microstructure Control

- Why is a non-consumable vacuum arc furnace typically selected for preparing AlFeCoCrNiCu high-entropy alloy substrates?

- Why is a vacuum device essential for removing air bubbles within simulated scrap steel? Enhance Your Fluid Experiments

- Why is a vacuum required for sulfur gas-phase diffusion? Boost Se-ZnS/HSC Cathode Sulfur Loading to 68.2 wt.%

- What are the process advantages of RTT vs. vacuum annealing for nickel-silicon? Achieve precise sub-micron control