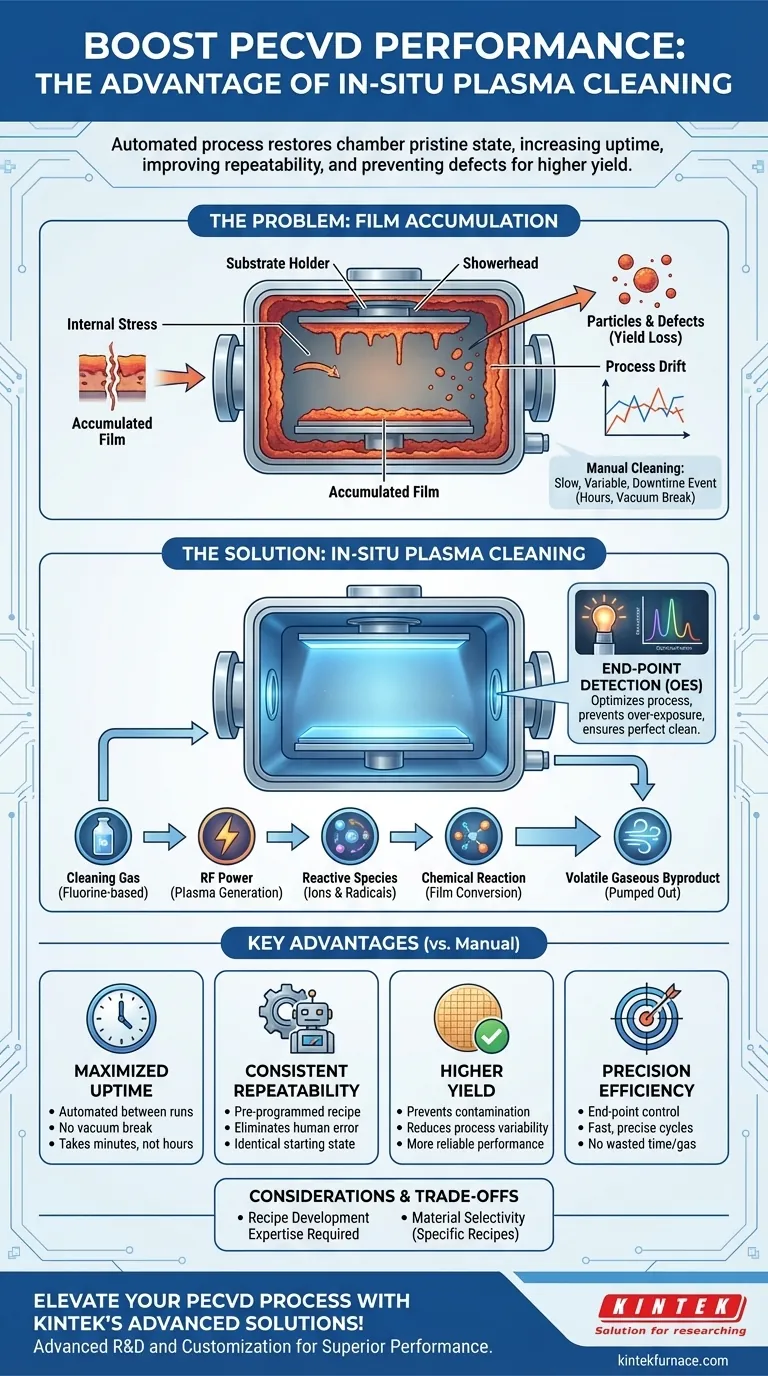

At its core, the primary advantage of in-situ plasma cleaning in a Plasma-Enhanced Chemical Vapor Deposition (PECVD) system is its ability to restore the chamber to a consistent, pristine state without manual intervention. This automated process significantly increases equipment uptime, improves process repeatability, and prevents defects caused by film accumulation, directly translating to higher yield and more reliable device performance.

Plasma cleaning is not merely a maintenance task; it is a critical process control strategy. It transforms the variable and time-consuming act of manual cleaning into a fast, repeatable, and automated step that is fundamental to achieving stable, high-volume manufacturing.

Why Chamber Cleaning is Non-Negotiable in PECVD

To understand the value of plasma cleaning, you must first understand the problem it solves. The PECVD process is designed to build thin films on a substrate, but it inevitably deposits that same material on all internal chamber surfaces, including the walls, showerhead, and substrate holder.

The Problem of Film Accumulation

With each deposition run, layers of material build up on the chamber hardware. This accumulated film develops internal stress. Eventually, this stress becomes too great, and the material cracks and flakes off into the chamber environment.

The Impact on Process Stability and Yield

These free-floating particles are a primary source of defects. If they land on a wafer during deposition, they can ruin the device being fabricated.

Furthermore, the buildup changes the thermal and electrical properties of the chamber itself. This "process drift" alters the plasma conditions from one run to the next, making consistent film deposition impossible and leading to unpredictable results and lower yields.

How Plasma Cleaning Works: An In-Situ Solution

Plasma cleaning addresses this challenge by using the system's own plasma-generating capability to remove the unwanted film deposits from the chamber walls. It is an in-situ process, meaning it occurs inside the sealed vacuum chamber between deposition runs.

Turning Deposition on Its Head

Think of plasma cleaning as the reverse of deposition. Instead of precursor gases that build a solid film, a cleaning gas (such as a fluorine-based compound) is introduced into the chamber.

The system's RF power energizes this gas, creating a plasma filled with highly reactive species (ions and radicals). These species react with the solid film deposited on the chamber walls, converting it into a volatile gaseous byproduct that is safely removed by the vacuum pump.

The Critical Role of End-Point Detection

Modern systems use end-point control to optimize this process. An optical emission spectrometer (OES) monitors the light, or "glow," emitted by the plasma.

The chemical byproducts of the cleaning reaction have a unique spectral signature. When the unwanted film has been fully removed, these byproducts disappear, and the plasma's light signature changes. The OES detects this change and automatically stops the cleaning process, ensuring a perfectly clean chamber without wasting time or gas and preventing damage to chamber components from over-exposure to the plasma.

Understanding the Trade-offs: Plasma vs. Manual Cleaning

While highly effective, it is important to view plasma cleaning in the context of its alternative: a manual "wet" clean.

Advantage: Uptime and Throughput

A manual clean is a significant downtime event. The chamber must be cooled, vented to atmosphere, physically opened, scrubbed by a technician, and then pumped back down to vacuum. This can take hours.

In contrast, an automated plasma clean typically takes only minutes and occurs between wafer runs without ever breaking vacuum. This maximizes equipment uptime and wafer throughput.

Advantage: Consistency and Repeatability

Manual cleaning is inherently variable, depending on the diligence of the technician. Plasma cleaning is a pre-programmed recipe executed precisely by the machine every time, eliminating human error and ensuring the chamber starts in an identical state before every deposition. This repeatability is essential for process control.

Limitation: Process Development

Developing a robust plasma clean recipe requires expertise. The choice of cleaning gas, power levels, and pressure must be carefully engineered to remove the target film efficiently without damaging the chamber's internal components. An improperly designed recipe can be ineffective or destructive.

Pitfall: Material Selectivity

A plasma clean recipe is highly selective for a specific material. A recipe designed to remove silicon nitride, for example, may be ineffective against silicon dioxide or other films. Running multiple processes in the same chamber may require developing and validating multiple cleaning recipes to manage residue.

Making the Right Choice for Your Goal

Integrating a plasma clean process requires treating it with the same seriousness as the deposition recipe itself.

- If your primary focus is high-volume manufacturing: Automated in-situ plasma cleaning with end-point control is non-negotiable for maximizing uptime, ensuring process stability, and achieving high yields.

- If your primary focus is research and development: While infrequent manual cleans may suffice initially, developing a validated plasma clean recipe is crucial for establishing a repeatable baseline and ensuring your experimental results are consistent.

- If your primary focus is process control: Leveraging end-point detection is the only way to guarantee the chamber is returned to a known, clean state before every run, which is the foundation of a stable process.

Ultimately, viewing the chamber clean not as janitorial work but as the first critical step of your deposition process is the key to mastering PECVD.

Summary Table:

| Aspect | Plasma Cleaning Advantage |

|---|---|

| Uptime | Increases by automating cleaning between runs without breaking vacuum |

| Repeatability | Ensures consistent chamber state, reducing process drift and defects |

| Yield | Improves by preventing particle contamination and process variability |

| Efficiency | Uses end-point detection for precise, fast cleaning cycles |

Elevate your PECVD process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our strong deep customization capability precisely meets your unique experimental needs, ensuring enhanced uptime, repeatability, and yield. Contact us today to discuss how we can optimize your setup for superior performance and reliability!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition