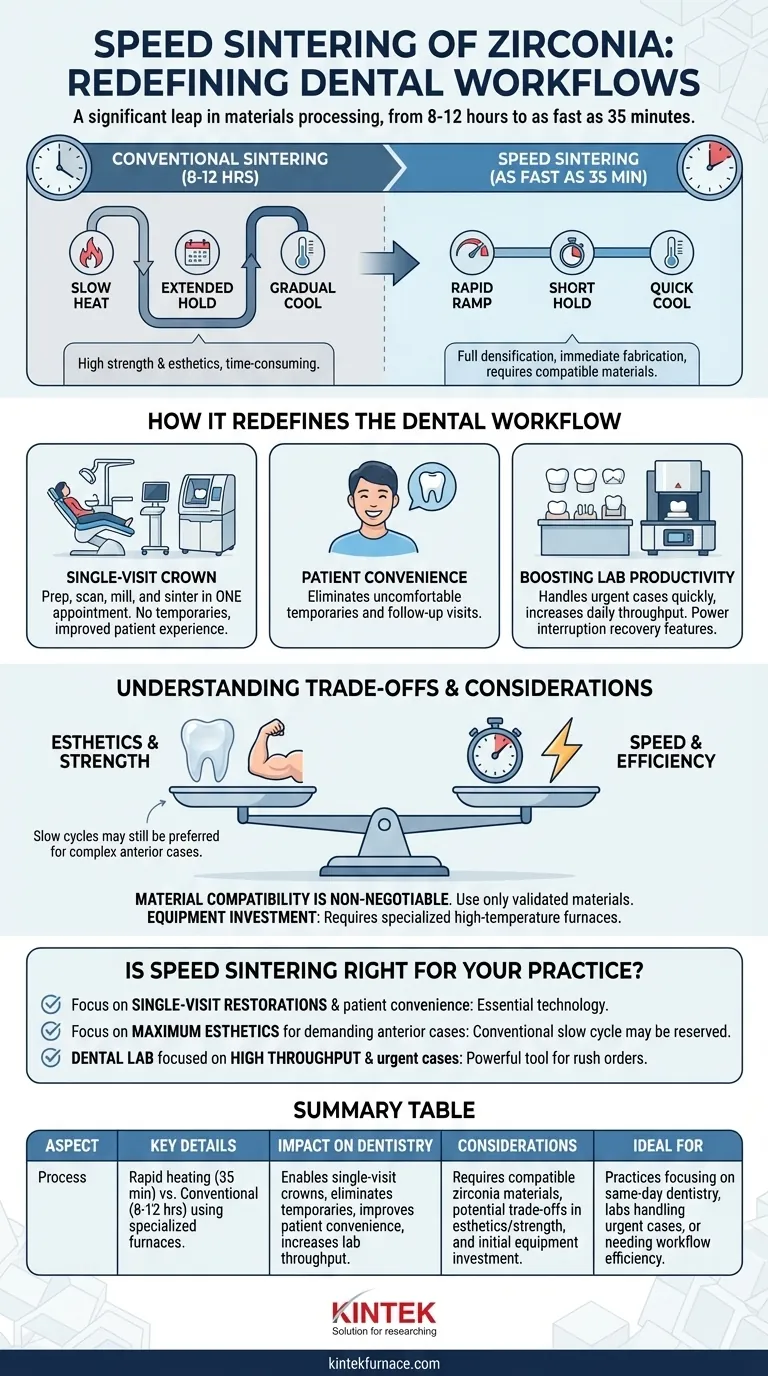

In modern prosthetic dentistry, speed sintering represents a significant leap forward in materials processing. It is an advanced fabrication method that uses rapid heating cycles and elevated temperatures to sinter zirconia restorations in as little as 35 minutes, a dramatic reduction from the 8-12 hours required for conventional sintering. This acceleration enables dental practices and labs to produce strong, permanent zirconia crowns, bridges, and inlays within a single patient visit.

Speed sintering is not merely an incremental improvement; it is a fundamental shift in the dental workflow. It trades the long, traditional firing cycle for unprecedented efficiency, but this requires a clear understanding of material compatibility and the specific clinical goals you aim to achieve.

How Speed Sintering Redefines the Dental Workflow

The primary impact of speed sintering is the radical compression of time. This change unlocks new possibilities for patient treatment and laboratory management, moving zirconia from a multi-day process to a potential chairside solution.

From Hours to Minutes: The Core Process

Conventional sintering works by slowly heating zirconia to a target temperature and holding it there for an extended period, allowing atoms to fuse and the material to densify. This "low and slow" approach ensures high strength and esthetics but is time-consuming.

Speed sintering uses a specialized furnace that can ramp up to very high temperatures much faster. By shortening the hold time at these elevated temperatures, it achieves full densification in a fraction of the time, making immediate fabrication possible.

Enabling the "Single-Visit Crown"

The most significant clinical advantage is the ability to offer a "one-day crown." A patient can have their tooth prepared, digitally scanned, and a permanent zirconia restoration milled and sintered while they wait.

This eliminates the need for uncomfortable temporary restorations and a follow-up appointment, dramatically improving the patient experience and overall convenience.

Boosting Laboratory Productivity

For dental labs, speed sintering enhances workflow flexibility and throughput. Furnaces designed for this process can often handle multiple units at once, allowing labs to process urgent cases quickly without disrupting their standard production schedule.

Features like power interruption recovery ensure that even these rapid cycles are secure, protecting against the loss of valuable restorations and maintaining a predictable workflow.

Understanding the Trade-offs and Considerations

While the benefits of speed are clear, adopting this technology requires a professional understanding of its limitations and specific requirements. It is not a universal replacement for all sintering protocols.

Material Compatibility is Non-Negotiable

Only zirconia materials specifically formulated and validated for rapid sintering cycles should be used. These materials are engineered to withstand the thermal stresses of rapid heating without compromising their structural integrity.

Using a conventional zirconia block in a speed cycle will likely result in a failed restoration with fractures, poor marginal fit, or compromised strength. Always match the material to the validated sintering program.

The Balance of Esthetics and Strength

Historically, the trade-off for speed was a potential reduction in translucency and, in some cases, flexural strength compared to a slow, conventional cycle. The extended time of a slow sinter allows for ideal grain growth, which can optimize esthetics.

However, modern speed-sintering zirconia and furnace technologies have significantly narrowed this gap. While a slow, multi-hour cycle may still be preferred for a highly complex anterior case demanding maximum esthetics, today's rapid-cycle materials deliver excellent, clinically acceptable results for the vast majority of cases.

Equipment and Initial Investment

Speed sintering requires a furnace capable of reaching high temperatures quickly and controlling the heating and cooling rates with precision. This represents a capital investment for a practice or lab looking to adopt the technology.

Is Speed Sintering Right for Your Practice?

The decision to integrate speed sintering should be based on your primary clinical and business objectives.

- If your primary focus is single-visit restorations and patient convenience: Speed sintering is an essential technology for offering same-day dentistry and maximizing chairside efficiency.

- If your primary focus is maximum esthetics for the most demanding anterior cases: You may still reserve the use of a conventional, slow sintering cycle to achieve the most predictable optical properties with certain high-translucency materials.

- If you are a dental lab focused on high throughput and urgent cases: A speed-sintering furnace is a powerful tool for managing rush orders and dramatically increasing your daily production capacity.

Ultimately, understanding these principles allows you to leverage speed sintering not just as a tool for speed, but as a strategic asset to meet specific clinical and patient needs.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | Rapid heating cycles (as fast as 35 min) vs. conventional 8-12 hours, using specialized high-temperature furnaces. |

| Impact on Dentistry | Enables single-visit crowns, eliminates temporary restorations, improves patient convenience, and increases lab throughput. |

| Considerations | Requires compatible zirconia materials, potential trade-offs in esthetics/strength, and initial equipment investment. |

| Ideal For | Practices focusing on same-day dentistry, labs handling urgent cases, or those needing workflow efficiency. |

Ready to transform your dental practice with advanced sintering solutions? At KINTEK, we specialize in high-temperature furnace technologies tailored for dentistry, including speed sintering systems. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Enhance efficiency, productivity, and patient care—contact us today to learn how our solutions can benefit your lab or practice!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns