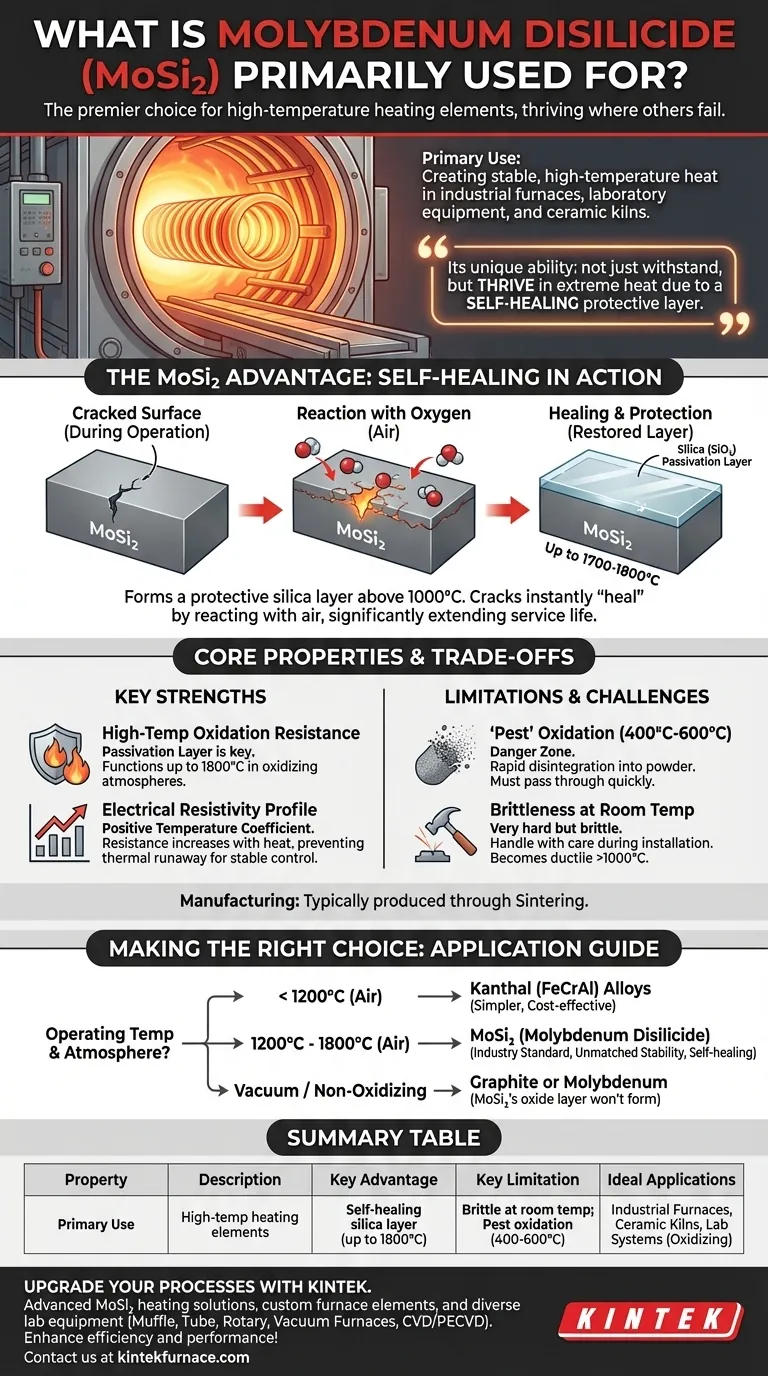

In short, Molybdenum Disilicide (MoSi₂) is primarily used to create high-temperature heating elements. Its unique properties allow it to operate reliably in industrial furnaces, laboratory equipment, and ceramic kilns at temperatures that would destroy conventional metal heaters.

The core reason MoSi₂ is so valuable is its ability to not just withstand extreme heat, but to thrive in it. It forms a self-healing, protective glass-like layer of silica (SiO₂) on its surface when heated, which prevents further oxidation and ensures a long service life at very high temperatures.

Why MoSi₂ Dominates High-Temperature Heating

Molybdenum Disilicide isn't just another material; it's a specialized solution for a critical industrial problem: generating stable, predictable heat in extreme environments.

The Core Property: High-Temperature Oxidation Resistance

The defining characteristic of MoSi₂ is its exceptional performance in oxidizing atmospheres. When heated above 1000°C, a thin, protective layer of silica (SiO₂) forms on its surface.

This passivation layer is the key to its success. It acts as a barrier, preventing oxygen from reaching and degrading the underlying material, allowing the element to function at temperatures up to 1700-1800°C.

Self-Healing in Action

If a crack or defect forms on this protective silica layer during operation, the exposed MoSi₂ underneath immediately reacts with oxygen in the air.

This reaction instantly "heals" the defect by forming new silica, restoring the protective barrier and dramatically extending the element's operational lifespan.

Electrical Resistivity Profile

MoSi₂ has a positive temperature coefficient of resistance. This means its electrical resistance increases as it gets hotter.

This property is highly desirable for heating elements, as it helps regulate power and prevent thermal runaway, contributing to a more stable and controllable heating process.

Understanding the Trade-offs

While MoSi₂ is exceptional, it is not a universally perfect material. Understanding its limitations is key to using it effectively.

The Challenge of "Pest" Oxidation

At lower temperatures, typically between 400°C and 600°C, MoSi₂ can suffer from a phenomenon known as pest oxidation.

In this temperature range, the material rapidly disintegrates into a powder. For this reason, heating elements must be designed to pass through this temperature zone quickly.

Brittleness at Room Temperature

Like many ceramics, MoSi₂ is very hard but also brittle at room temperature. This requires careful handling during installation and maintenance to prevent fractures.

It only becomes ductile and less prone to fracture at very high temperatures, well above 1000°C.

Manufacturing and Forming

Most MoSi₂ heating elements are produced through sintering, a process of compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction.

More advanced techniques like plasma spraying can create dense, complex shapes, but these methods are less common for standard heating elements.

Making the Right Choice for Your Application

Selecting the right heating element technology depends entirely on your operational temperature requirements and budget.

- If your primary focus is operating below 1200°C: Simpler and less expensive metallic alloys like Kanthal (FeCrAl) are often sufficient and more cost-effective.

- If your primary focus is operating between 1200°C and 1800°C: Molybdenum Disilicide (MoSi₂) is the industry standard due to its unmatched stability, long life, and self-healing properties in air.

- If your primary focus is operating in a vacuum or non-oxidizing atmosphere: Other materials like graphite or pure molybdenum may be more suitable, as MoSi₂'s key advantage (its oxide layer) cannot form.

Ultimately, choosing MoSi₂ is a decision to invest in reliable, long-term performance for the most demanding high-temperature applications.

Summary Table:

| Property | Description |

|---|---|

| Primary Use | High-temperature heating elements in furnaces, kilns, and lab equipment |

| Key Advantage | Self-healing silica layer for oxidation resistance up to 1800°C |

| Key Limitation | Brittle at room temperature; susceptible to pest oxidation at 400-600°C |

| Ideal Applications | Industrial furnaces, ceramic kilns, laboratory heating systems in oxidizing atmospheres |

Upgrade your high-temperature processes with KINTEK's advanced MoSi2 heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable, long-lasting furnace elements. Our products, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are backed by deep customization to meet your unique experimental needs. Contact us today to enhance efficiency and performance in your lab!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing