At its core, the rotary kiln design process is a methodical translation of your material's unique properties into a robust, reliable piece of thermal processing equipment. It is not an off-the-shelf purchase but a custom-engineered solution, beginning with a deep analysis of the material and proceeding through systematic testing and scaling to ensure the final machine meets specific process goals.

The central principle of kiln design is that the material itself dictates the machine's final form and function. Every design decision—from the kiln's diameter and slope to its drive power and refractory lining—is a direct response to the thermal and physical behavior of the material being processed.

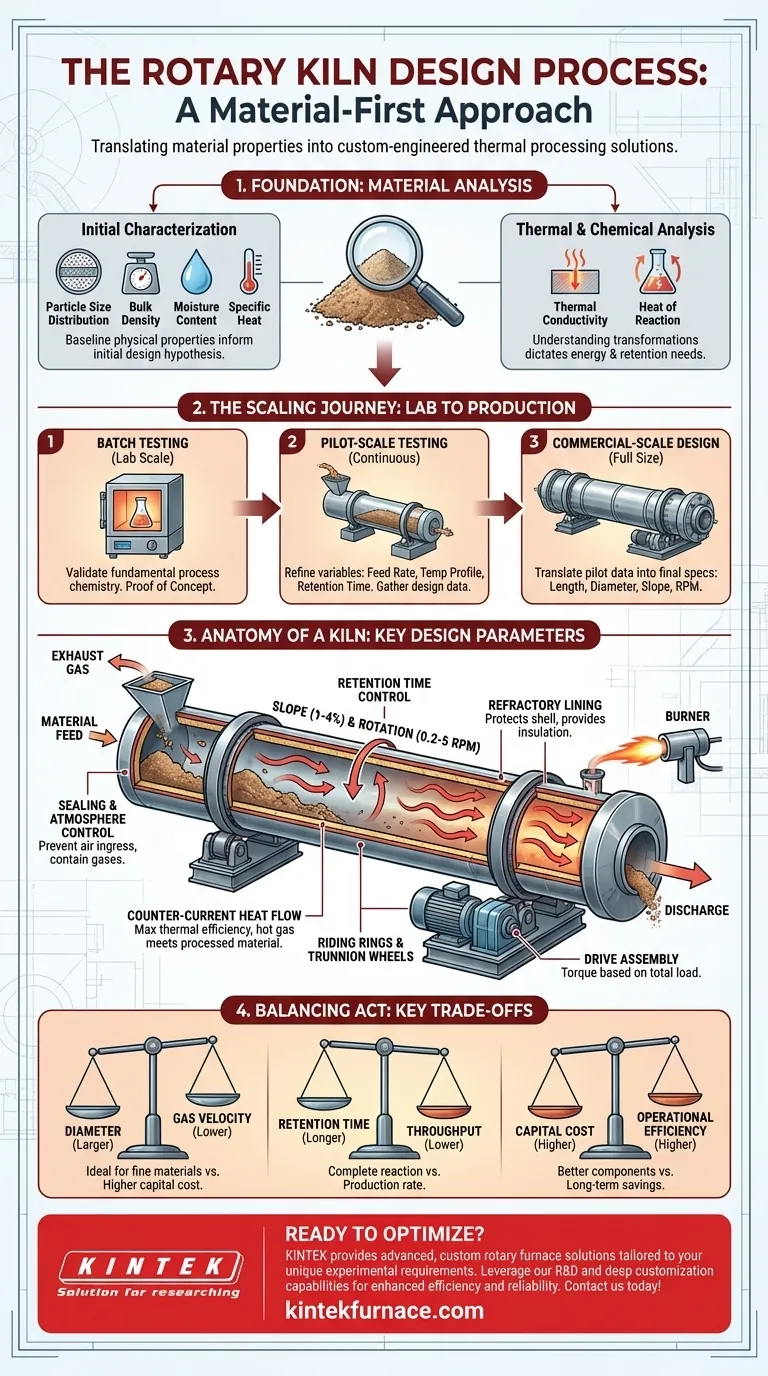

The Material-First Design Philosophy

A rotary kiln is fundamentally a reactor designed around a single variable: the material. The entire engineering process is built upon understanding how this material behaves under heat and movement.

Initial Material Characterization

Before any testing begins, a baseline understanding of the material is critical. Key properties are measured to inform the initial design hypothesis. These include particle size distribution, bulk density, moisture content, and specific heat. For instance, a high-density material will require a more powerful drive assembly, while very fine powders may necessitate a larger kiln diameter to reduce gas velocity and prevent the material from being carried out with the exhaust.

The Role of Thermal & Chemical Analysis

This stage goes deeper, examining how the material transforms. Thermal conductivity dictates how efficiently heat transfers through the material bed, influencing required temperatures and retention time. The heat of reaction (whether a reaction absorbs or releases energy) is crucial for calculating the total energy required from the burner and ensuring the process is stable.

From Lab to Production: The Scaling Process

With a theoretical understanding of the material, the design process moves into physical testing. This multi-stage approach de-risks the project by proving the process at a small scale before committing to a full-size build.

Batch Testing: Proving the Concept

The first step is often batch testing in a small laboratory kiln. The primary goal is simple: to confirm that the desired physical or chemical transformation can be achieved under controlled conditions. This validates the fundamental process chemistry and provides initial data points.

Pilot-Scale Testing: Refining the Variables

This is the most critical phase for gathering design data. A continuous, pilot-scale kiln is used to process the material, allowing engineers to refine key variables. Here, they determine the optimal feed rate, temperature profile across the kiln's length, and the precise retention time needed to achieve the final product specifications. The data from these trials is the blueprint for the commercial unit.

Commercial-Scale Design: Translating Data into Steel

The validated data from pilot testing is used to model and engineer the full-size commercial kiln. The refined retention time, for example, directly informs the final calculation of the kiln's length, diameter, rotational speed, and slope. This ensures the commercial kiln will replicate the successful results achieved at the pilot scale.

Core Mechanical and Thermal Design Parameters

The data gathered in the previous stages translates directly into the kiln's physical components and operational parameters.

Sizing and Inclination (The Slope Effect)

A rotary kiln is set at a slight downward angle, typically between 1% and 4%. This slope, combined with the kiln's rotational speed (usually 0.2 to 5 RPM), dictates how fast the material moves through the cylinder, directly controlling the retention time.

Rotation System and Drive Assembly

The heavy steel shell rotates on massive riding rings which are supported by trunnion wheels. A powerful motor and gearbox—the drive assembly—provide the torque for rotation. The design of this entire system is based on the total load, which is determined by the material's bulk density and the kiln's size.

Heat Flow and Zoning (Counter-Current Design)

For maximum thermal efficiency, most kilns use a counter-current flow. Material is fed into the high end, and the burner is located at the low (discharge) end. This means the hottest gases encounter the most processed material, efficiently transferring heat as the gas cools on its way to the feed end. The kiln is often conceptually divided into zones for drying, preheating, and reacting (calcining).

Refractory Lining: Protecting the Shell

The inside of the steel shell is lined with a refractory material (specialized heat-resistant brick or castable). This layer serves two purposes: it protects the steel shell from the extreme internal process temperatures and provides insulation to prevent heat loss, improving energy efficiency.

Sealing and Atmosphere Control

Seals are installed at the feed and discharge ends of the kiln. Their function is critical: they prevent cold ambient air from being drawn into the system, which would disrupt temperature control and waste fuel. They also contain process gases and dust, ensuring a safe and compliant operation.

Understanding the Trade-offs

Designing a rotary kiln involves balancing competing priorities. Understanding these trade-offs is essential for specifying a machine that is both effective and economical.

Diameter vs. Gas Velocity

A larger diameter kiln results in lower internal gas velocity for a given flow rate. This is ideal for fine materials that could otherwise become entrained in the exhaust gas stream. However, a larger diameter also means a higher capital cost. This is a key trade-off between material suitability and project budget.

Retention Time vs. Throughput

If a material requires a long retention time for a complete reaction, the kiln must be proportionally longer or operate at a slower rotational speed. Both options can limit the maximum throughput (tons per hour), creating a direct trade-off between product quality and production rate.

Capital Cost vs. Operational Efficiency

Investing more upfront in high-efficiency components can yield significant long-term savings. Advanced burner systems, higher-quality refractory, and superior sealing systems increase the initial capital cost but reduce ongoing fuel consumption and maintenance expenses over the life of the kiln.

Making the Right Choice for Your Goal

Your specific objective should guide where you focus your attention during the design and specification process.

- If your primary focus is achieving a specific chemical reaction: Insist on rigorous pilot testing to precisely define the required temperature profile and retention time.

- If your primary focus is maximizing throughput and efficiency: Pay close attention to the heat flow design (counter-current), exhaust gas handling, and kiln sealing systems to minimize energy loss.

- If your primary focus is handling a novel or difficult material: Never skip the initial material characterization and batch testing phases, as this foundational data is non-negotiable for success.

A methodical, material-first approach ensures your rotary kiln becomes a predictable and efficient asset, not a source of operational challenges.

Summary Table:

| Design Phase | Key Activities | Key Parameters |

|---|---|---|

| Material Characterization | Analyze particle size, density, moisture, specific heat | Bulk density, particle size distribution |

| Thermal & Chemical Analysis | Study conductivity, heat of reaction | Thermal conductivity, heat of reaction |

| Pilot-Scale Testing | Refine feed rate, temperature profile, retention time | Retention time, temperature profile |

| Commercial-Scale Design | Model kiln size, rotation, slope | Length, diameter, rotational speed, slope |

| Mechanical Design | Specify drive assembly, refractory lining, seals | Drive power, refractory type, seal efficiency |

Ready to optimize your thermal processing with a custom rotary kiln? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Rotary Furnaces, tailored for industries like mining, chemicals, and materials science. Our strong deep customization capability ensures your unique experimental requirements are met precisely, enhancing efficiency and reliability. Contact us today to discuss how we can support your project goals!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials