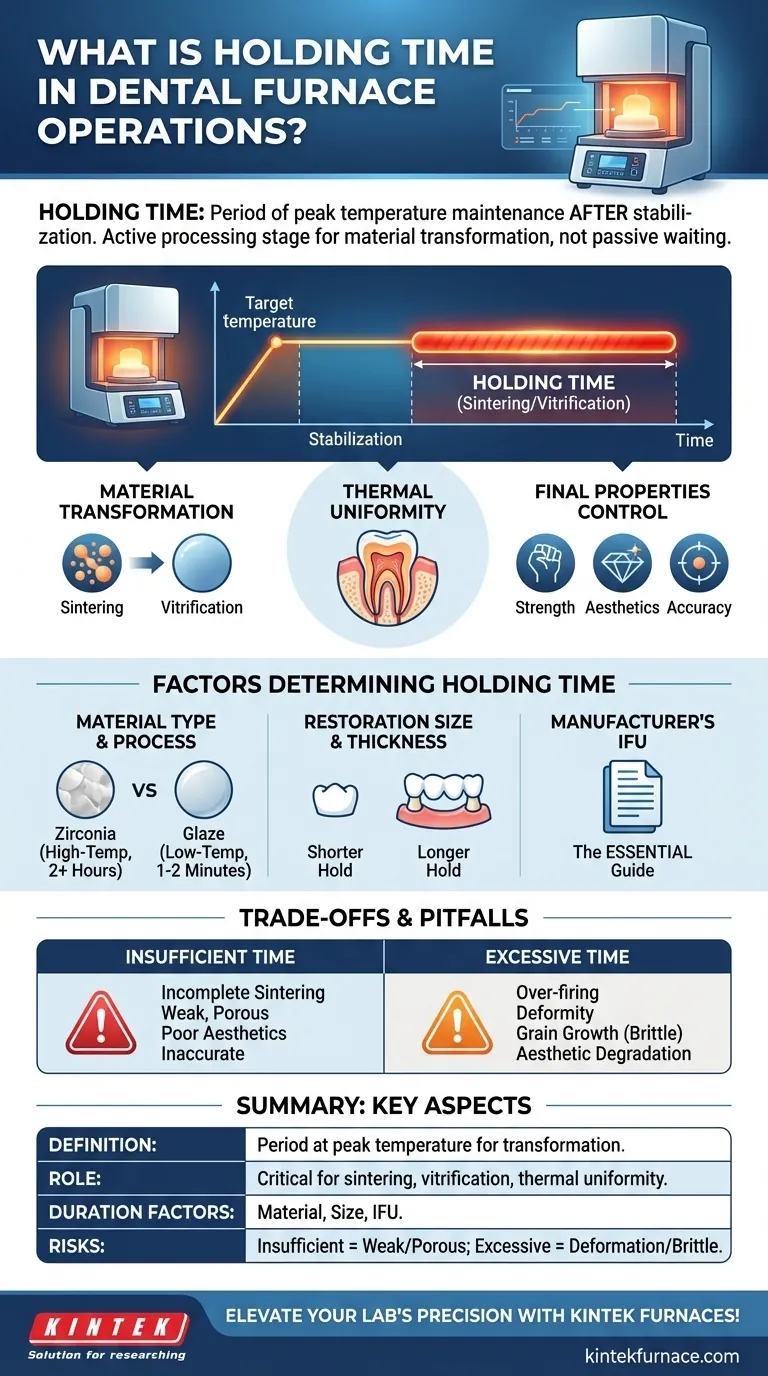

In dental furnace operations, holding time is the specific period during which the furnace maintains its peak target temperature. This phase begins only after the furnace has reached the programmed temperature and the heat has stabilized, ensuring the entire chamber and the restoration within it are at a uniform, consistent heat.

Holding time is not a passive waiting period; it is the active processing stage where the desired material transformation occurs. The duration of this hold directly determines the final strength, aesthetics, and accuracy of a dental restoration.

The Role of Holding time in the Firing Cycle

A firing program is a recipe of time and temperature. Holding time, also known as the "soak" or "dwell" time, is arguably the most critical step in that recipe.

A Critical Phase of Material Transformation

This is the stage where the real work happens. For zirconia, this is when sintering—the process of fusing particles into a dense, strong solid—reaches completion. For porcelains, it's when vitrification (glazing) occurs, creating a smooth, non-porous surface.

Ensuring Thermal Uniformity

Reaching a target temperature is not enough. The holding time allows the heat to fully penetrate and saturate the entire restoration, from the thinnest edge to the thickest point. This thermal equilibrium is essential for preventing internal stresses that could lead to fractures later on.

Controlling Final Material Properties

The length of the hold directly influences the outcome. A correct hold achieves the desired translucency, shade, and strength. An incorrect hold can ruin the material, wasting time and resources.

Factors That Determine the Correct Holding Time

The ideal holding time is not a universal constant. It is dictated by the specific material, the restoration's characteristics, and the manufacturer's validated protocols.

Material Type and Process

Different materials require vastly different holding times. The high-temperature sintering of a zirconia framework might require a hold of two hours or more. In contrast, a low-temperature glaze firing might only need a hold of one to two minutes.

Restoration Size and Thickness

A large, multi-unit zirconia bridge requires a longer hold than a small, single-unit crown. The extra mass needs more time to achieve complete thermal uniformity at its core.

Manufacturer's Instructions for Use (IFU)

The material manufacturer has conducted extensive testing to find the optimal firing parameters. The IFU is the single most important guide for setting holding time, temperature, and ramp rates. Deviating from it introduces significant risk.

Understanding the Trade-offs and Common Pitfalls

Precision is key. Both too little and too much holding time can lead to a failed restoration.

The Risk of Insufficient Holding Time

Cutting the hold short is a common mistake made to save time. This can result in:

- Incomplete Sintering: The restoration will be weak, porous, and may appear chalky.

- Poor Aesthetics: The material may not achieve the target translucency or shade.

- Dimensional Inaccuracy: The restoration may not shrink correctly, leading to a poor fit.

The Danger of Excessive Holding Time

A longer hold is not always better. Over-soaking the material can be just as destructive, causing:

- Over-firing: The restoration can slump or deform, losing its anatomical shape.

- Grain Growth: In materials like zirconia, excessive heat can cause crystals to grow too large, paradoxically making the material more brittle.

- Aesthetic Degradation: The restoration may become too translucent, or its shade can be altered.

Misinterpreting "Stabilization"

The hold timer must begin only after the furnace temperature is stable. Most modern furnaces manage this automatically, but it's a critical principle. If the hold begins while the temperature is still fluctuating, the effective processing time will be shorter than programmed.

Setting the Right Holding Time for Your Goal

The ideal holding time is always a balance between achieving complete material transformation and avoiding thermal damage. Always start with the manufacturer's IFU as your baseline.

- If your primary focus is maximum strength (e.g., full-contour zirconia): Adhere strictly to the manufacturer's recommended long holding time to ensure full and uniform sintering.

- If your primary focus is surface aesthetics (e.g., staining and glazing): Use a precise, often shorter, holding time to achieve surface vitrification without altering the underlying shade or causing slumping.

- If you are working with large-span or very thick restorations: Ensure you are using the correct program for larger units, which often includes a longer holding time to guarantee complete thermal soaking.

Mastering holding time is fundamental to moving from simply operating a furnace to consistently producing high-quality, predictable dental restorations.

Summary Table:

| Aspect | Key Details |

|---|---|

| Definition | Period at peak temperature for material transformation in dental furnaces. |

| Role | Critical for sintering (zirconia), vitrification (porcelain), and thermal uniformity. |

| Duration Factors | Material type, restoration size/thickness, manufacturer's IFU. |

| Risks | Insufficient time: weak, porous results; Excessive time: deformation, brittleness. |

Elevate your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure these solutions perfectly match your unique experimental needs, helping you achieve consistent, high-quality restorations with optimal holding times. Contact us today to discuss how we can support your success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations