In modern dentistry, dental porcelain is a specialized ceramic material designed to expertly mimic the appearance, feel, and function of natural tooth enamel. It is the go-to material for a wide range of restorative and cosmetic treatments because it combines strength, biocompatibility, and unparalleled aesthetic qualities, allowing dentists to rebuild smiles in a way that is both durable and virtually undetectable.

The core challenge in dental restoration is finding a material that is strong enough to withstand the forces of chewing while also being beautiful enough to blend in seamlessly. Dental porcelain is the premier solution because it uniquely delivers on both of these requirements, offering a superior balance of lifelike aesthetics and functional durability.

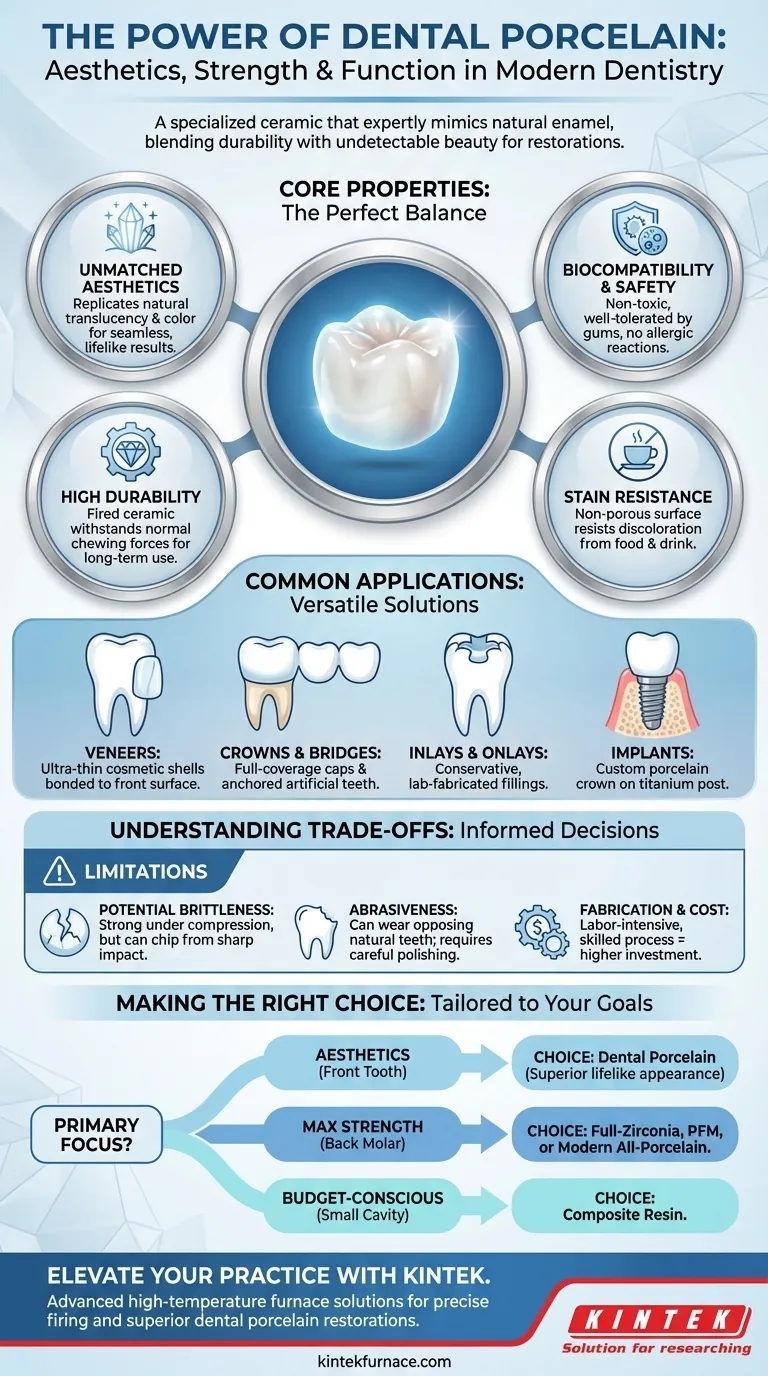

The Core Properties of Dental Porcelain

The widespread use of dental porcelain is not accidental. It stems from a specific combination of physical and biological properties that make it exceptionally well-suited for use in the human mouth.

Unmatched Aesthetics

Porcelain's most celebrated quality is its ability to replicate the translucency and color of natural teeth. It can be meticulously layered and color-matched to the patient's surrounding teeth, making restorations like crowns and veneers appear completely natural.

Biocompatibility and Safety

Dental porcelain is biocompatible, meaning it is non-toxic and well-tolerated by the body. It does not cause allergic reactions or irritation to the sensitive gum tissues that surround the tooth.

Durability and Strength

When properly fired in a specialized porcelain furnace, this ceramic becomes a hard, dense material capable of withstanding normal chewing and biting forces. This makes it a reliable choice for long-term restorations.

Stain Resistance

Unlike porous natural enamel or composite resin materials, dental porcelain is non-porous and highly resistant to staining. This helps restorations maintain their original color for years, even with exposure to coffee, tea, or tobacco.

Common Applications in Restorative Dentistry

Dental porcelain's versatility allows it to be used in various forms to address different clinical needs, from minor repairs to complete smile makeovers.

Dental Veneers

Veneers are ultra-thin shells of porcelain bonded to the front surface of teeth. They are used primarily for cosmetic purposes to correct issues like discoloration, chips, gaps, or minor misalignment.

Crowns and Bridges

A crown is a full-coverage "cap" placed over a heavily damaged or decayed tooth to restore its shape, size, and strength. A bridge uses crowns on adjacent teeth to anchor one or more artificial teeth, "bridging" the gap left by missing teeth.

Inlays and Onlays

These are more conservative restorations than crowns. An inlay fits within the cusps (bumps) of a tooth, while an onlay covers one or more of these cusps. They are essentially lab-fabricated fillings that offer superior durability and fit.

Dental Implants

While the implant itself is a titanium post secured in the jawbone, the visible, tooth-like portion that attaches to it is almost always a custom-made porcelain crown.

Understanding the Trade-offs

No material is perfect, and being an informed patient or practitioner means understanding the limitations of dental porcelain.

Potential for Brittleness

While very strong under compression (biting down), porcelain can be brittle. A sharp, focused impact—such as biting down on an olive pit or using teeth to open something—can cause it to chip or fracture.

Abrasiveness to Opposing Teeth

Some types of dental porcelain can be harder than natural tooth enamel. Over many years, this can cause accelerated wear on the opposing natural teeth it bites against. Dentists carefully select and polish the porcelain to minimize this risk.

Fabrication and Cost

Creating a high-quality porcelain restoration is a labor-intensive process that requires significant technical skill and specialized equipment. This level of craftsmanship means that porcelain restorations typically carry a higher cost than alternatives like composite resin or metal alloys.

Making the Right Choice for Your Restoration

The best material always depends on the specific clinical situation and your personal goals.

- If your primary focus is aesthetics for a front tooth: Dental porcelain is almost always the superior choice due to its lifelike appearance.

- If your primary focus is maximum strength for a back molar: A full-zirconia or porcelain-fused-to-metal (PFM) crown may be recommended, though modern all-porcelain options are also very strong.

- If your primary focus is a budget-conscious repair for a small cavity: Composite resin is often the most practical and effective solution.

Understanding the unique balance of beauty and strength that dental porcelain offers empowers you to have a more informed discussion with your dental professional about the best solution for your health.

Summary Table:

| Property | Description |

|---|---|

| Aesthetics | Mimics natural tooth translucency and color for seamless appearance |

| Biocompatibility | Non-toxic and safe for gums, reducing allergic reactions |

| Durability | Withstands chewing forces when properly fired for long-term use |

| Stain Resistance | Non-porous surface resists discoloration from food and drinks |

Elevate your dental practice with KINTEK's advanced high-temperature furnace solutions! Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, backed by deep customization capabilities, ensure precise firing for durable, aesthetically perfect dental porcelain restorations. Whether you're crafting crowns, veneers, or implants, we help labs achieve superior results efficiently. Contact us today to discuss how our tailored solutions can meet your unique needs and enhance patient outcomes!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does an efficient cooling system benefit dental furnace operations? Boost Productivity and Quality in Your Lab

- What are the risks of inadequate dental furnace ventilation? Protect Your Lab Quality & Team Safety

- What happens if the timing is incorrect during a dental furnace operation? Avoid Ruined Restorations

- What is the use of porcelain in dentistry? Achieve Lifelike, Durable Dental Restorations

- What should routine inspections of dental furnaces include? Ensure Consistent, High-Quality Dental Restorations