At its core, a vacuum arc furnace is a highly specialized piece of metallurgical equipment designed for remelting and purifying metals and alloys. Its primary purpose is to produce materials with exceptional purity, a refined crystal structure, and superior mechanical properties by using a high-energy electric arc to melt a consumable electrode within a tightly controlled vacuum.

While many furnaces use a vacuum to prevent contamination, the Vacuum Arc Furnace (VAR) is unique. It leverages the intense, focused energy of an electric arc to systematically remelt a metal electrode, effectively "distilling" it to remove dissolved gases and impurities that would compromise performance in critical applications.

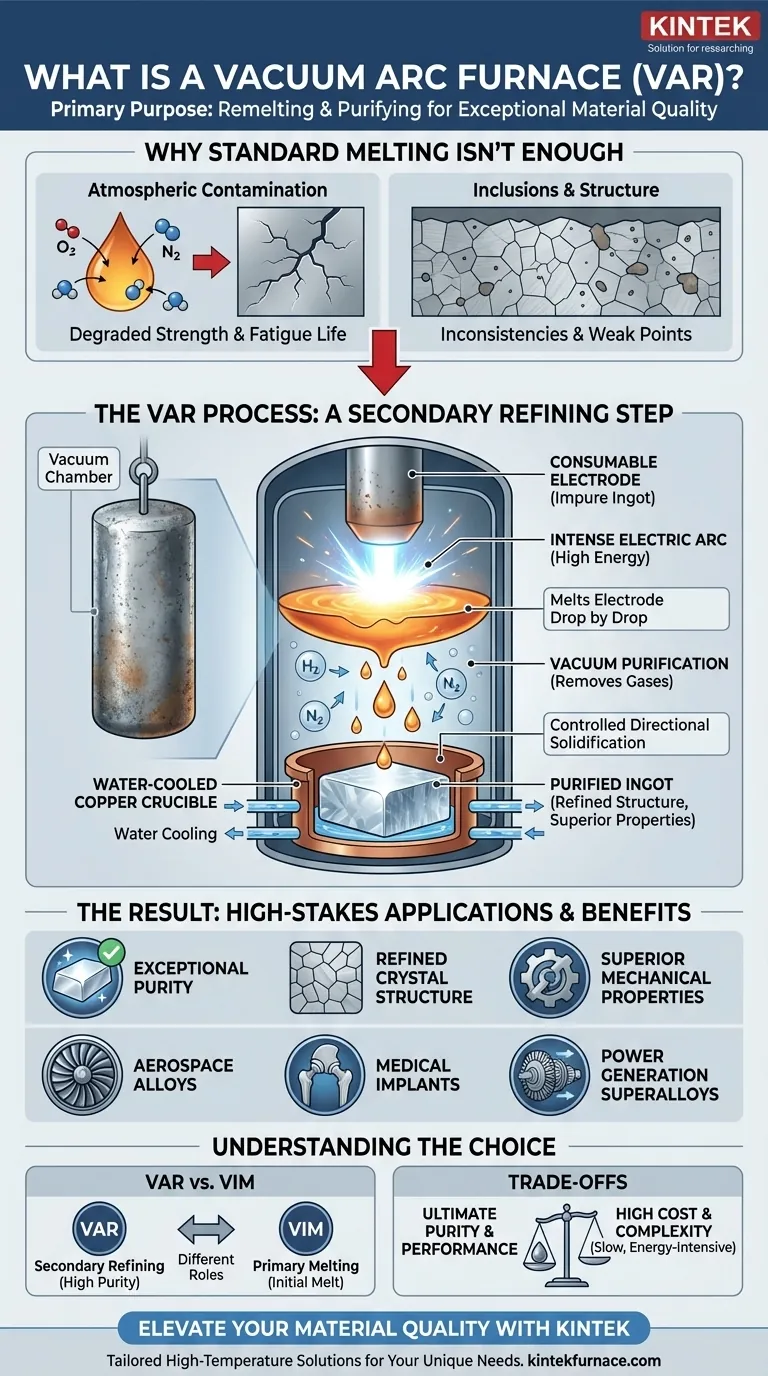

The Core Problem: Why Standard Melting Isn't Enough

The demand for high-performance materials in sectors like aerospace, medical implants, and power generation exposes the limits of conventional melting processes.

The Enemy: Atmospheric Contamination

Many advanced metals, especially reactive ones like titanium and zirconium, readily absorb atmospheric gases like oxygen and nitrogen at high temperatures. These absorbed gases form imperfections that can act as microscopic crack initiation points, severely degrading the material's strength and fatigue life.

The Challenge of Inclusions and Structure

Standard melting can also trap non-metallic impurities (inclusions) within the solidified metal. Furthermore, uncontrolled cooling can lead to a coarse, non-uniform grain structure, creating inconsistencies and weak points throughout the final product.

How a Vacuum Arc Furnace Solves the Problem

The process performed in this furnace is called Vacuum Arc Remelting (VAR). It is not a primary melting process but a secondary refining step for materials that have already been melted once.

The Principle of VAR

The process begins with a solid cylinder of the alloy to be purified, known as a consumable electrode. This electrode is suspended inside a water-cooled copper crucible within a sealed vacuum chamber.

The Arc: Intense, Localized Heat

A high-current DC electric arc is struck between the bottom of the electrode and a small amount of starter material in the crucible. The intense heat of the arc, reaching thousands of degrees, progressively melts the tip of the electrode drop by drop.

The Vacuum: An Active Purifier

As each metal droplet forms and falls, it is exposed to the vacuum. This exposure is critical, as it pulls dissolved gases (like hydrogen and nitrogen) out of the molten metal before it has a chance to solidify.

The Result: A Purified Ingot

The molten droplets collect and solidify in the water-cooled crucible, forming a new, highly purified ingot from the bottom up. This controlled, directional solidification process pushes remaining impurities towards the top of the ingot and results in an exceptionally clean, uniform crystalline structure.

Understanding the Trade-offs and Key Applications

While powerful, the VAR process is not a universal solution. It is a specific tool for a specific set of challenges.

When to Use VAR: High-Stakes Materials

VAR is the gold standard for producing the ultra-pure materials required for demanding applications. This includes titanium alloys for jet engine components, specialty steels for landing gear and bearings, and superalloys for gas turbines and medical implants.

How VAR Differs from Other Vacuum Furnaces

It's crucial not to confuse VAR with other vacuum furnace types. A Vacuum Induction Melting (VIM) furnace, for example, uses electromagnetic induction to melt material in a crucible. VIM is excellent for creating a primary melt from raw materials, and often, a VIM ingot becomes the consumable electrode for a subsequent VAR cycle to achieve even higher purity.

The Cost and Complexity

The VAR process is slow, energy-intensive, and requires significant capital investment and operator expertise. Its use is justified only when the material's performance requirements are so extreme that no other process can meet the standard.

Making the Right Choice for Your Goal

Selecting the correct vacuum metallurgy process depends entirely on your end-use requirements for purity and structural integrity.

- If your primary focus is ultimate purity and structural integrity for reactive or high-performance alloys: The Vacuum Arc Remelting (VAR) process is the definitive choice for this secondary refining step.

- If your primary focus is creating a high-quality primary melt from raw or scrap materials: A Vacuum Induction Melting (VIM) furnace is the more appropriate technology for the initial melt.

- If your primary focus is simply heat treating, brazing, or sintering without melting: A standard vacuum furnace without a specialized melting mechanism is the correct and most cost-effective tool.

Understanding the unique role of the electric arc in the remelting process is the key to leveraging this technology to achieve unparalleled material quality.

Summary Table:

| Feature | Description |

|---|---|

| Primary Purpose | Remelt and purify metals to achieve high purity and superior mechanical properties |

| Key Process | Vacuum Arc Remelting (VAR) using an electric arc in a vacuum |

| Main Benefits | Removes dissolved gases, refines crystal structure, reduces impurities |

| Ideal Applications | Aerospace alloys, medical implants, specialty steels, superalloys |

| Key Components | Consumable electrode, water-cooled copper crucible, vacuum chamber |

Ready to elevate your material quality with precision high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs for ultra-pure metals in critical applications. Contact us today to discuss how our tailored solutions can enhance your research and production outcomes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency