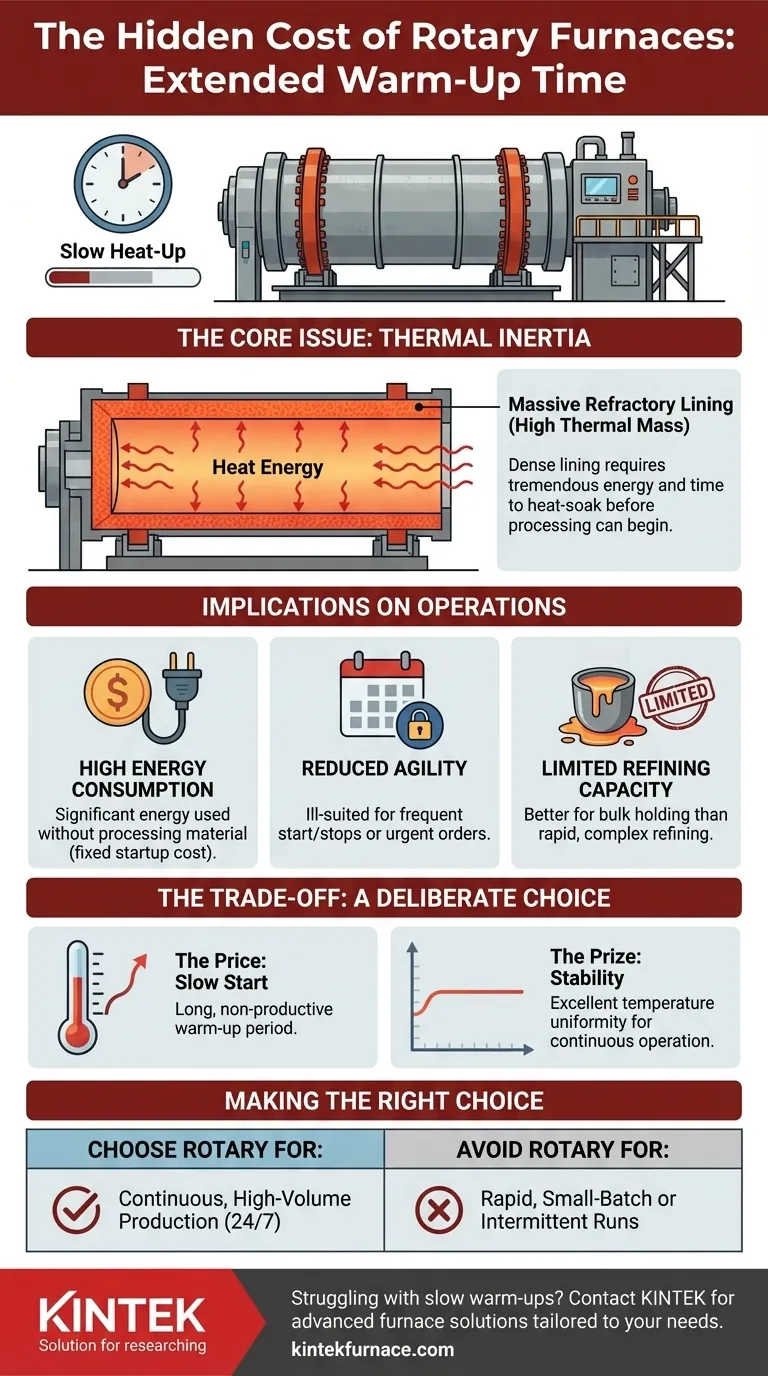

A primary drawback of rotary furnaces is their extended warm-up time. Compared to other industrial heating methods, these furnaces can take a significant amount of time to reach their target operating temperature, which presents a notable disadvantage for any process sensitive to production schedules.

The core issue is not just the wait but the underlying reason: a rotary furnace's massive refractory lining creates high thermal inertia. This design choice, while excellent for temperature stability, makes the furnace inherently slow and energy-intensive to start, impacting both operational agility and cost.

The Core Issue: Thermal Inertia

The slow warm-up is a direct consequence of the furnace's fundamental design, which is optimized for retaining heat once it gets hot.

Understanding Refractory Linings

Rotary furnaces are lined with heavy, dense, ceramic-like materials known as refractories. The purpose of this lining is to withstand extreme temperatures and protect the outer steel shell.

The Physics of Slow Heating

This dense refractory lining possesses a high thermal mass. It requires a tremendous amount of energy to be absorbed over a prolonged period before its temperature rises to the required level. The furnace cannot begin its work until the lining is thoroughly heat-soaked and stable.

The Impact on Cycle Times

For any operation that isn't running 24/7, this warm-up period adds significant, non-productive time to every production cycle. A furnace that takes hours to heat up cannot be started and stopped quickly to meet fluctuating demand.

Operational and Financial Implications

The time delay is not just an inconvenience; it has direct consequences for efficiency and your bottom line.

Increased Energy Consumption

The entire warm-up phase is a period of high energy consumption without any material being processed. This initial energy expenditure is a fixed cost for every startup, making short or intermittent production runs less economical.

Reduced Operational Flexibility

A furnace with a long startup time is ill-suited for agile manufacturing environments. It cannot respond quickly to urgent orders or frequent changes in the production schedule, locking you into longer, pre-planned batches.

Limited Refining Capacity

Because of the time and energy investment required to get them to temperature, rotary furnaces are often used for bulk melting or holding rather than rapid, complex refining. Their design often requires pre-processed materials to maximize the efficiency of each long cycle.

Understanding the Trade-offs

The slow warm-up is a deliberate engineering trade-off, not simply a design flaw. The same property that makes it slow to heat up also provides its primary benefits.

The Benefit: Excellent Temperature Stability

Once a rotary furnace reaches its operating temperature, its high thermal mass makes it incredibly stable. It resists temperature fluctuations, ensuring a uniform and consistent heating environment for the material inside, which is critical for process quality.

When Slow Warm-up Isn't a Problem

For facilities that operate continuously (24/7), the initial warm-up time becomes a negligible, one-time event. In this context, the furnace's stability and efficiency during steady-state operation are far more important than its startup speed.

A Comparison to Alternatives

Other technologies, like induction furnaces, heat up extremely quickly by directly energizing the metal charge. However, they may not offer the same large-volume batch mixing and holding capabilities that a rotary furnace provides.

Making the Right Choice for Your Operation

Choosing the right furnace requires aligning its inherent characteristics with your specific production goals and schedule.

- If your primary focus is continuous, high-volume production: The long warm-up time of a rotary furnace is a minor, one-time cost that is easily outweighed by its excellent temperature stability and processing capacity.

- If your primary focus is rapid, small-batch processing or frequent startups: The significant warm-up period will be a major operational bottleneck and lead to prohibitively high energy costs per unit produced.

Understanding this fundamental trade-off between thermal inertia and operational agility is the key to selecting the most effective heating technology for your needs.

Summary Table:

| Aspect | Impact |

|---|---|

| Warm-up Time | Extended, leading to delays |

| Energy Consumption | High during startup, increasing costs |

| Operational Flexibility | Reduced, limiting agile production |

| Best Use Case | Continuous, high-volume operations |

Struggling with slow furnace warm-ups? KINTEK offers advanced high-temperature furnace solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems with deep customization to optimize efficiency and reduce downtime. Contact us today to enhance your lab's performance and cut operational costs!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing