In essence, a porcelain furnace is a high-temperature oven used in dental laboratories to transform ceramic materials into durable and lifelike dental restorations. Its primary role is to fire and sinter materials like porcelain, fusing particles together to create strong, custom-fitted prosthetics such as crowns, veneers, and bridges that precisely match a patient's natural teeth.

The porcelain furnace is not merely a heat source; it is a precision instrument that bridges the gap between raw ceramic material and a final, biocompatible dental restoration. It enables the controlled fusion—or sintering—that provides both the aesthetic beauty and the structural integrity required for modern dentistry.

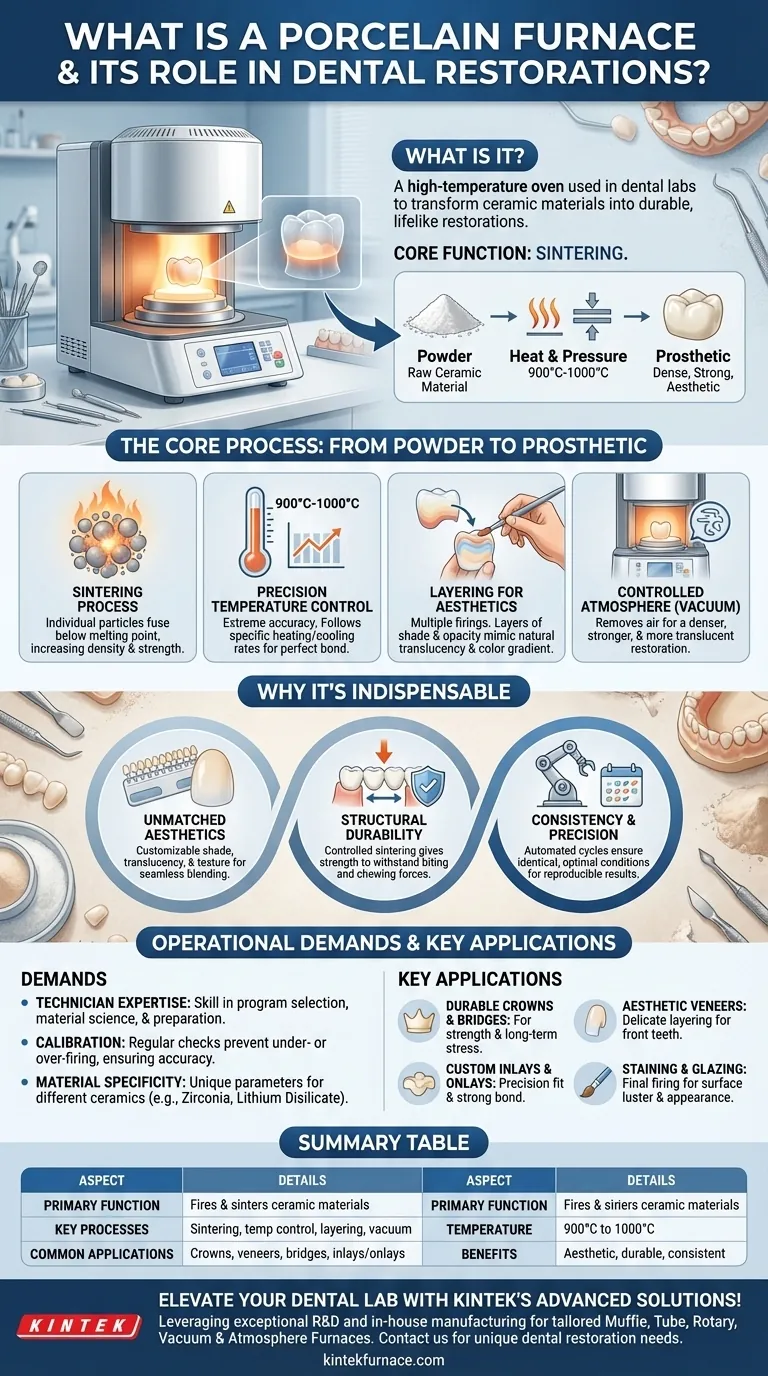

The Core Function: From Powder to Prosthetic

A porcelain furnace's true value lies in its ability to execute a highly controlled thermal process. This process turns a fragile, chalky ceramic into a dense, non-porous, and robust final product.

The Sintering Process

Sintering is the fundamental process at work. The furnace heats the ceramic material to a temperature just below its melting point, causing the individual particles to fuse together. This significantly increases the density and strength of the restoration.

Precision Temperature Control

These furnaces operate with extreme accuracy, often managing temperatures between 900°C and 1000°C. They follow pre-programmed firing cycles with specific heating rates, hold times, and cooling rates to ensure the porcelain bonds perfectly to its substructure without cracking or distortion.

Layering for Natural Aesthetics

A single restoration may undergo multiple firings. A dental technician skillfully applies layers of porcelain in different shades and opacities to mimic the natural translucency and color gradient of a real tooth. Each layer is fired separately to build up a final, lifelike appearance.

Creating a Controlled Atmosphere

Many advanced furnaces create a vacuum during the firing cycle. This removes air and impurities from between the porcelain particles, resulting in a denser, stronger, and more translucent final restoration.

Why the Furnace Is Indispensable

The quality of a final crown, veneer, or bridge is directly dependent on the precision of the firing process. The furnace is the critical tool for achieving the required clinical and aesthetic standards.

Ensuring Unmatched Aesthetics

The furnace allows technicians to customize the shade, translucency, and surface texture of a restoration. This ensures the final product blends seamlessly with the patient's surrounding dentition, making it virtually indistinguishable from a natural tooth.

Guaranteeing Structural Durability

The controlled sintering process is what gives a ceramic restoration its strength and longevity. A properly fired crown can withstand the significant forces of biting and chewing for years, making it a reliable and long-lasting solution.

Delivering Consistency and Precision

Modern porcelain furnaces come with programmable firing cycles for different types of ceramic materials. This automation ensures that every restoration is fired under identical, optimal conditions, leading to consistent and reproducible results day after day.

Understanding the Operational Demands

While essential, a porcelain furnace is a sophisticated tool that requires expertise and diligence to operate effectively. Its output is only as good as the technician and the processes behind it.

The Critical Role of the Technician

The furnace is not a "set and forget" device. The skill of the dental technician in selecting the right program, preparing the ceramic, and understanding the material science is paramount to achieving a successful outcome.

Calibration is Non-Negotiable

To maintain temperature accuracy, furnaces require regular calibration. An uncalibrated furnace can lead to under-fired (weak) or over-fired (brittle or distorted) restorations, compromising the entire workflow.

Material-Specific Requirements

Different dental ceramics, such as feldspathic porcelain, lithium disilicate, or zirconia, have unique firing parameters. The furnace and the technician must be equipped to handle this versatility, as a one-size-fits-all approach will lead to failure.

Key Applications in Dental Prosthetics

The porcelain furnace is a versatile workhorse, central to the creation of nearly all fixed ceramic restorations.

- If your goal is a durable crown or bridge: The furnace's ability to sinter ceramic provides the essential strength needed to withstand long-term functional stress.

- If your goal is a highly aesthetic veneer: The furnace enables the delicate layering and shade matching required for a seamless and natural-looking result on front teeth.

- If your goal is a custom inlay or onlay: Its precision ensures a perfect fit and strong bond, restoring a portion of a tooth with a durable and aesthetic material.

- If your goal is custom staining and glazing: The final firing cycle is used to apply surface stains and a glaze, which perfects the tooth's luster and final appearance.

Ultimately, the porcelain furnace is the cornerstone technology that makes modern, aesthetic restorative dentistry possible.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Function | Fires and sinters ceramic materials for dental restorations |

| Key Processes | Sintering, precision temperature control, layering, vacuum atmosphere |

| Temperature Range | 900°C to 1000°C |

| Common Applications | Crowns, veneers, bridges, inlays/onlays, custom staining and glazing |

| Benefits | Aesthetic matching, structural durability, consistency in results |

Elevate your dental lab's precision and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for dental restorations. Contact us today to discuss how our furnaces can enhance your prosthetic outcomes and streamline your workflow!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations