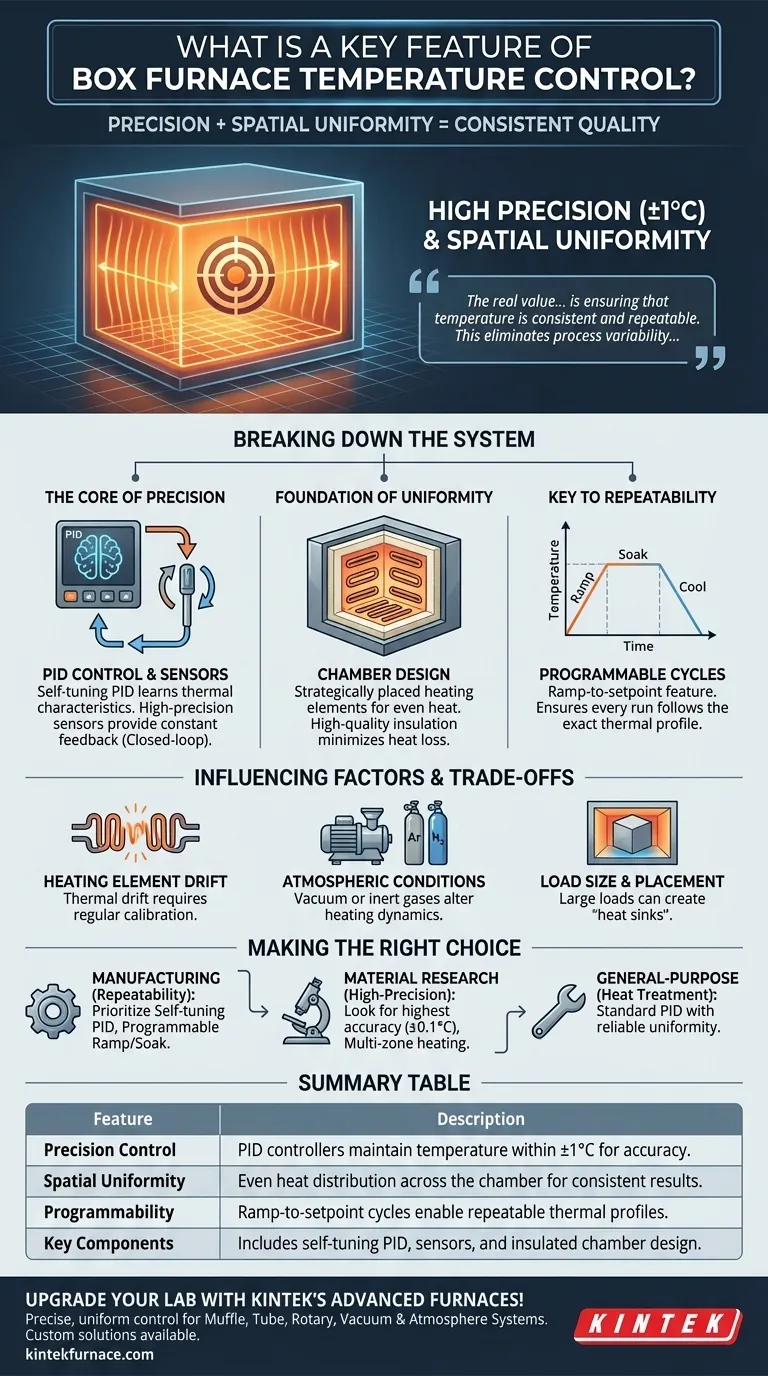

A defining feature of a box furnace's temperature control is its combination of high precision and spatial uniformity. This means the furnace not only reaches a specific temperature with pinpoint accuracy—often within ±1°C—but also maintains that exact temperature evenly across the entire heating chamber, ensuring every part of the material receives the same thermal treatment.

The real value of a box furnace isn't just hitting a target temperature, but ensuring that temperature is consistent and repeatable. This eliminates process variability, which is the root cause of inconsistent quality in heat treatment, material testing, and component manufacturing.

Breaking Down Box Furnace Temperature Control

A box furnace's effectiveness hinges on a system of integrated components working together. Understanding this system reveals why these furnaces are staples in labs and industrial settings.

The Core of Precision: PID Control and Sensors

The brain of the temperature control system is the PID (Proportional-Integral-Derivative) controller. This isn't just a simple thermostat.

Modern box furnaces often feature self-tuning PID instrumentation. The controller automatically learns the thermal characteristics of the furnace and calculates the optimal settings to prevent overshooting the target temperature and minimize fluctuations.

This is paired with high-precision temperature sensors, such as thermocouples, which provide constant feedback to the controller. This closed-loop system allows the furnace to maintain its setpoint with remarkable accuracy.

The Foundation of Uniformity: Chamber Design

Achieving precision is pointless if the heat is unevenly distributed. This is where the physical design of the furnace becomes critical.

Strategically placed heating elements, often made of resistance wire, are positioned to deliver heat evenly throughout the chamber.

High-quality insulation, typically multi-layered ceramic fiber, minimizes heat loss to the outside environment. This not only improves energy efficiency but also helps create a highly stable and uniform internal thermal environment.

The Key to Repeatability: Programmable Cycles

Many modern box furnaces include a ramp-to-setpoint feature. This allows operators to program the rate of temperature increase (or decrease).

This programmability is crucial for sensitive materials that could be damaged by thermal shock if heated too quickly. It also ensures that every production run follows the exact same thermal profile, a cornerstone of quality control and process repeatability.

Understanding the Trade-offs and Influencing Factors

While highly effective, the performance of a box furnace's temperature control is not absolute. Several factors can influence its real-world accuracy and uniformity.

Heating Element Drift

Resistance wire heating elements can degrade over time, a phenomenon known as thermal drift. This can cause the furnace's actual temperature to deviate from the controller's setpoint. Regular calibration using certified thermocouples is essential to mitigate this and ensure long-term accuracy.

Atmospheric Conditions

The atmosphere inside the furnace impacts heat transfer. Standard air-atmosphere furnaces are most common, but specialized applications may require a controlled atmosphere.

Vacuum furnaces prevent oxidation at high temperatures, while furnaces using inert gases like argon or nitrogen offer protection for specific materials. These controlled atmospheres can alter heating dynamics, requiring specialized PID tuning.

Load Size and Placement

Placing a very large or dense object inside the furnace can create a "heat sink," temporarily causing localized cool spots. Proper loading procedures and allowing adequate soak time are necessary to ensure the entire part reaches a uniform temperature.

Making the Right Choice for Your Goal

Selecting a box furnace requires matching its control capabilities to your specific application's needs.

- If your primary focus is process repeatability for manufacturing: Prioritize furnaces with self-tuning PID controllers and programmable ramp/soak cycles to ensure every batch is identical.

- If your primary focus is high-precision material research or calibration: Look for models with the highest accuracy specifications (e.g., ±0.1°C to ±1°C) and consider features like multi-zone heating for maximum uniformity.

- If your primary focus is general-purpose heat treatment: A standard furnace with reliable PID control and good insulation will suffice, but always verify its uniformity specifications meet your minimum quality standards.

Ultimately, precise and uniform temperature control is the mechanism that delivers reliable, predictable, and high-quality results from any thermal process.

Summary Table:

| Feature | Description |

|---|---|

| Precision Control | PID controllers maintain temperature within ±1°C for accuracy. |

| Spatial Uniformity | Even heat distribution across the chamber for consistent results. |

| Programmability | Ramp-to-setpoint cycles enable repeatable thermal profiles. |

| Key Components | Includes self-tuning PID, sensors, and insulated chamber design. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnaces! We specialize in delivering precise, uniform temperature control tailored to your unique needs. Our product line—featuring Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by deep customization capabilities to meet exact experimental requirements. Contact us today to discuss how our solutions can enhance your process reliability and quality!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits