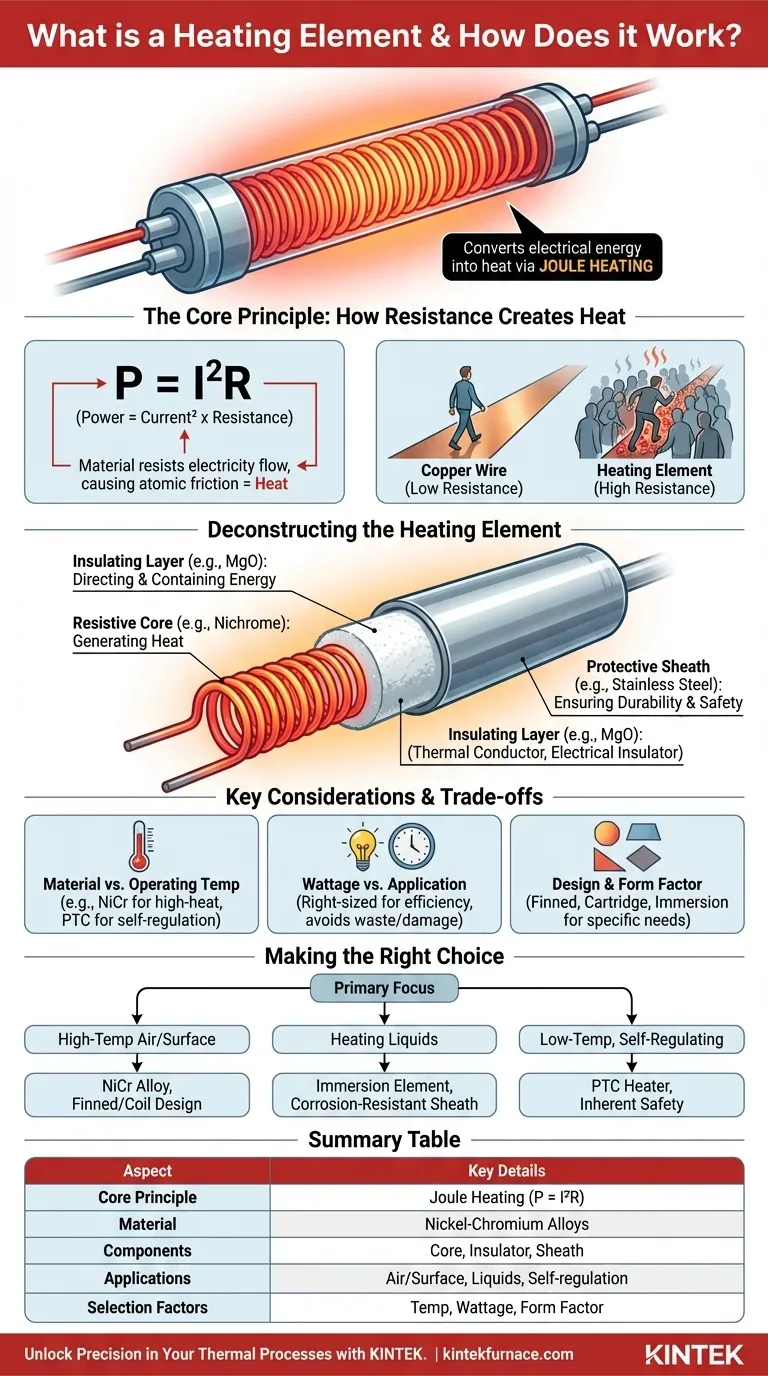

At its core, a heating element is a specialized component designed to convert electrical energy into heat. It accomplishes this through a physical principle known as Joule heating, where the material of the element intentionally resists the flow of electricity, causing atomic-level friction that manifests as thermal energy.

The critical insight is that heating elements are not simply wires that get hot. They are precisely engineered systems that use materials with high electrical resistance to generate heat efficiently, while using insulation and protective sheaths to deliver that heat safely and durably.

The Core Principle: How Resistance Creates Heat

To truly understand a heating element, you must first understand the foundational physics. The entire process hinges on harnessing a property that is normally undesirable in electrical circuits: resistance.

The Science of Joule Heating

When an electric current flows through any conductor, electrons are forced to move through the material's atomic structure. In a heating element, the material is chosen to make this journey difficult. The flowing electrons collide with the atoms of the resistive material, and these repeated collisions transfer kinetic energy, causing the atoms to vibrate more intensely. This increased atomic vibration is what we perceive as heat.

The Role of Resistance

The amount of heat generated is directly defined by Joule's first law, often expressed as P = I²R. In this formula, P is power (heat), I is current, and R is resistance. While current is a factor, the formula shows that heat increases with the square of the current, but linearly with resistance. For designers, resistance is the most critical variable to manipulate. By selecting materials with high intrinsic resistance, they can generate substantial heat with a manageable amount of electrical current.

An Analogy: The Crowded Hallway

Imagine electricity flowing through a wire is like a person walking down a hallway.

- A copper wire is like an empty hallway. It has very low resistance, so the person can walk through easily with almost no effort or friction.

- A heating element is like a densely crowded hallway. It has high resistance, forcing the person to push and jostle their way through. All of that friction and interaction generates a lot of "heat" and slows the person down.

Deconstructing the Heating Element

A functional heating element is more than just its resistive wire. It is a complete assembly where each part serves a distinct and vital purpose.

The Resistive Core: The Engine of Heat

This is the heart of the element. It is typically not a common wire but a specialized metal alloy, most famously nickel-chromium (Nichrome). These alloys are chosen for their key properties: high electrical resistance to generate heat effectively and a very high melting point to withstand the temperatures they create.

The Insulating Layer: Directing and Containing Energy

Surrounding the resistive core is a layer of electrical insulation, commonly compacted magnesium oxide (MgO) powder. This material is a fascinating paradox: it is an excellent electrical insulator, preventing the current from shorting to the outer casing, but it is also a good thermal conductor, efficiently transferring the heat from the core outwards.

The Protective Sheath: Ensuring Durability and Safety

The outermost layer is a metal sheath, often made of stainless steel or other corrosion-resistant alloys. This sheath protects the internal components from moisture, oxidation, and physical damage. It also provides a safe surface for mounting and for the transfer of heat to the surrounding environment, whether it be air, water, or a solid surface.

Understanding the Trade-offs and Key Considerations

Selecting the right heating element is a process of balancing competing factors. There is no single "best" element; there is only the best one for a specific job.

Material vs. Operating Temperature

The material of the resistive core dictates its maximum operating temperature. A nickel-chromium element is ideal for high-heat applications like an oven or industrial furnace. In contrast, a PTC (Positive Temperature Coefficient) polymer element is better for applications requiring lower temperatures and self-regulation, as its resistance automatically increases at a certain temperature, limiting its own heat output.

Wattage vs. Application

Wattage measures the heat output over time. It is crucial to match the element's wattage to the application's needs. An undersized element will fail to reach the target temperature, while an oversized element will waste energy, overshoot the temperature, and potentially damage the material being heated or the element itself.

Design and Form Factor

The physical shape of the element is critical for efficient heat transfer.

- Finned elements increase their surface area to heat air more effectively in convection ovens or duct heaters.

- Cartridge heaters are cylindrical and designed to be inserted into drilled holes to heat metal blocks.

- Immersion heaters use sealed, corrosion-resistant sheaths to heat liquids directly.

Making the Right Choice for Your Application

To apply this knowledge, match the element's characteristics to your primary goal.

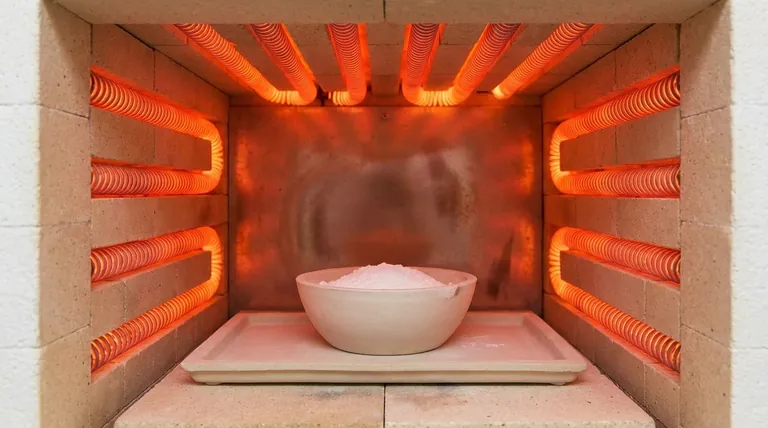

- If your primary focus is high-temperature air or surface heating: You need an element with a nickel-chromium alloy core and a design, like a coil or finned strip, that maximizes surface area.

- If your primary focus is heating liquids: You must select an immersion-style element with a sheath material (like stainless steel or Incoloy) that resists corrosion from the specific liquid.

- If your primary focus is low-temperature, self-regulating heat: A PTC heater is the superior choice, as it provides inherent safety by preventing overheating without complex external controls.

Understanding these core principles transforms a heating element from a simple "hot wire" into a precise tool for thermal engineering.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Principle | Converts electrical energy to heat through Joule heating (P = I²R) |

| Material | Nickel-chromium alloys (e.g., Nichrome) for high resistance and melting point |

| Components | Resistive core, insulating layer (e.g., MgO), protective sheath (e.g., stainless steel) |

| Applications | High-temperature air/surface heating, liquid immersion, low-temperature self-regulation |

| Selection Factors | Operating temperature, wattage, form factor (e.g., finned, cartridge, immersion) |

Unlock Precision in Your Thermal Processes with KINTEK

Struggling to find the right heating solution for your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your experimental requirements.

Whether you're working with high-temperature materials, corrosive liquids, or need self-regulating heat, we can design a heating element that ensures efficiency, safety, and durability. Contact us today to discuss how our expertise can enhance your lab's performance and accelerate your research!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production