At its core, a fluidized bed vertical tube furnace is an advanced heating system that uses an upward flow of gas to suspend solid particulate matter, causing it to behave like a fluid. This unique design combines the vertical structure of a tube furnace with the dynamic process of fluidization to achieve exceptionally uniform and efficient heating for materials processing or combustion.

This furnace solves a critical engineering challenge: how to heat small, solid particles evenly and quickly. By suspending the particles in a hot gas stream, it eliminates hot spots and maximizes surface contact, leading to superior process control and efficiency compared to conventional static furnaces.

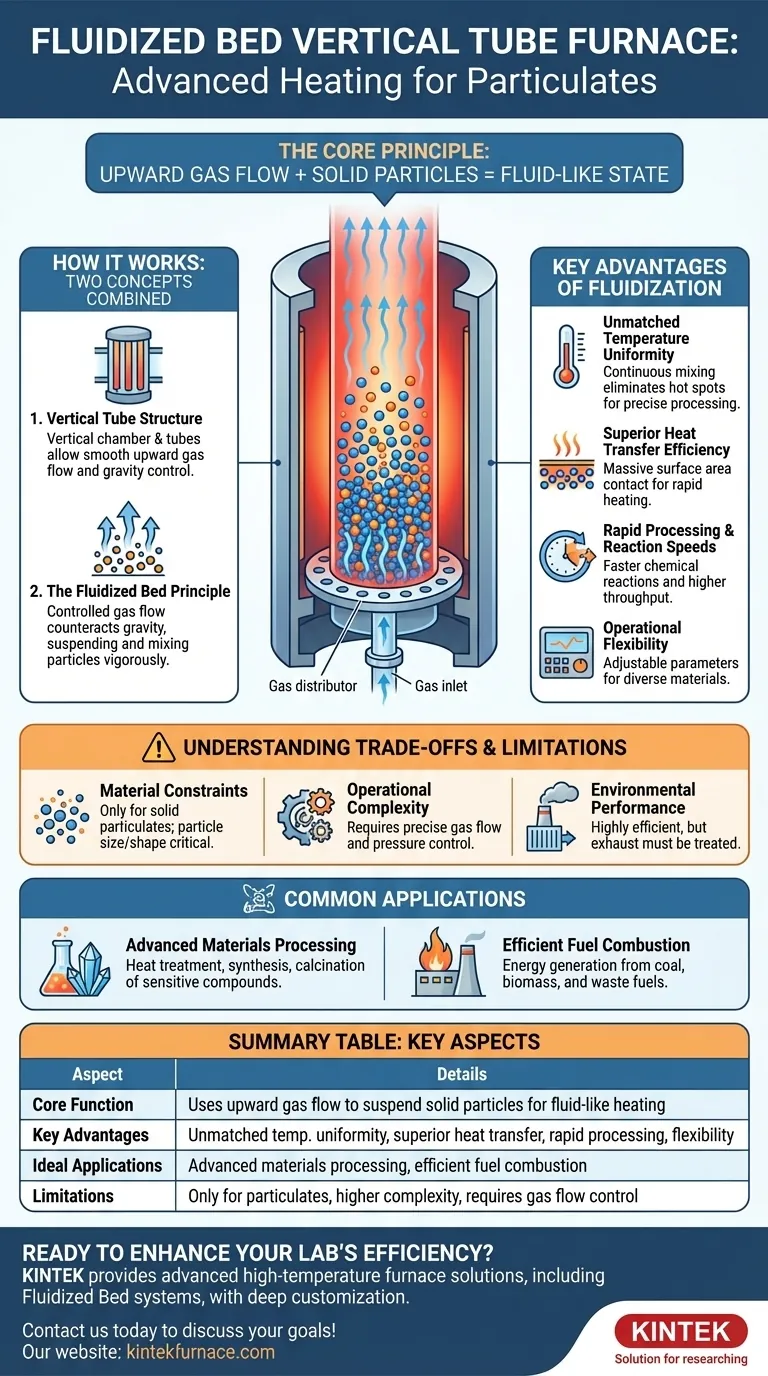

How It Works: Combining Two Core Concepts

The furnace's name perfectly describes its operation, which merges a physical structure with a dynamic process. Understanding these two parts is key to grasping its capabilities.

The Vertical Tube Furnace Structure

The foundation is a vertical furnace body. Inside this chamber, one or more tubes are arranged vertically.

This vertical orientation is crucial as it allows gas to flow upward smoothly, working with gravity to control the process within the tubes.

The Fluidized Bed Principle

The "fluidized bed" is not a physical object but a state of matter created by the process. Gas is forced upwards through the bottom of the vertical tubes where the solid particles (the material to be heated or the fuel) are located.

By carefully controlling the gas flow rate and pressure, the upward force of the gas counteracts gravity. This lifts and separates the solid particles, causing them to become suspended and move vigorously within the gas stream.

The Result: A Suspended, "Liquid-Like" Bed

The mixture of gas and suspended, churning particles behaves much like a boiling liquid. This "fluidized" state is the furnace's main advantage, as it ensures constant motion and mixing of the solid material.

The Key Advantages of Fluidization

The unique "liquid-like" state of the material inside the furnace delivers several significant performance benefits that are difficult to achieve with other heating methods.

Unmatched Temperature Uniformity

Because the solid particles are in constant motion, they are all exposed to the same temperature. This continuous mixing eliminates hot spots and temperature gradients, which is critical for sensitive heat treatment processes like calcination or annealing.

Superior Heat Transfer Efficiency

Fluidization massively increases the contact surface area between the hot gas and each solid particle. This direct, extensive contact allows for extremely rapid and efficient heat transfer, reducing the energy and time required to bring the material to the desired temperature.

Rapid Processing and Reaction Speeds

Since the particles heat up very quickly, chemical reactions, syntheses, or combustion processes occur much faster. This leads to higher throughput and productivity in both laboratory and industrial settings.

Operational Flexibility

The process is highly controllable. Operators can precisely adjust the temperature, gas composition, and gas flow rate to fine-tune the reaction conditions, making the furnace adaptable to a wide range of materials and applications.

Understanding the Trade-offs and Limitations

While powerful, this technology is not universally applicable. Its specialized nature comes with specific constraints.

Material Constraints: It's for Particulates

This furnace is designed exclusively for solid particulate materials. It cannot be used to heat large, solid objects. The size, shape, and density of the particles are also critical factors that must be matched to the furnace's design to achieve proper fluidization.

Operational Complexity

Compared to a simple box furnace, a fluidized bed system is more complex. It requires precise control over gas flow and pressure, adding variables that must be managed to ensure stable and effective operation.

Environmental Performance

When used for combustion, the process is highly efficient. However, like any combustion system, the exhaust gas must be treated to meet environmental emission standards. The advantage here is that the controlled nature of the combustion often makes this purification process more manageable.

Common Applications

The unique characteristics of these furnaces make them ideal for specific, high-performance tasks across research and industry.

Advanced Materials Processing

They are widely used in laboratories and production facilities for heat treatment applications that demand high precision. This includes the synthesis and purification of compounds, oxidation, diffusion, calcination, and thermal annealing of sensitive inorganic or organic materials.

Efficient Fuel Combustion

The furnace's ability to handle various particulate fuels, such as coal, biomass, or waste materials, makes it an effective tool for energy generation. The high combustion temperature and efficiency ensure maximum energy extraction while providing good control over emissions.

Making the Right Choice for Your Goal

The decision to use this technology depends entirely on your material and processing requirements.

- If your primary focus is unparalleled temperature uniformity for sensitive powders: A fluidized bed vertical tube furnace is likely the superior choice.

- If your primary focus is efficiently combusting diverse particulate fuels: This technology offers significant advantages in both heat transfer and adaptability.

- If your goal is to heat a single, large solid object or you require simple, low-cost operation: A conventional muffle or tube furnace would be a more practical solution.

Ultimately, this furnace is a specialized instrument engineered to deliver exceptional control and efficiency for particulate-based thermal processes.

Summary Table:

| Aspect | Details |

|---|---|

| Core Function | Uses upward gas flow to suspend solid particles for fluid-like heating |

| Key Advantages | Unmatched temperature uniformity, superior heat transfer efficiency, rapid processing, operational flexibility |

| Ideal Applications | Advanced materials processing (e.g., calcination, synthesis), efficient fuel combustion (e.g., coal, biomass) |

| Limitations | Only for particulate materials, higher operational complexity, requires gas flow control |

Ready to enhance your lab's efficiency with a custom fluidized bed furnace?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Whether you're processing sensitive powders or optimizing fuel combustion, our expertise ensures superior performance and reliability. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency