Ultimately, the requirement for a retort-based muffle furnace is dictated by the process, not the industry. Any application requiring absolute atmospheric integrity at high temperatures will necessitate a retort. Industries such as aerospace, medical device manufacturing, advanced materials science, and powder metallurgy frequently rely on these designs to prevent contamination and ensure the chemical and physical properties of the final product.

The decision to use a retort is not about choosing an older design, but about a specific engineering need: creating a physically sealed, gas-tight barrier between the part being processed and the furnace's heating elements and insulation. When even trace amounts of contamination can cause product failure, a retort is the only reliable solution.

What is a Retort and Why is it Different?

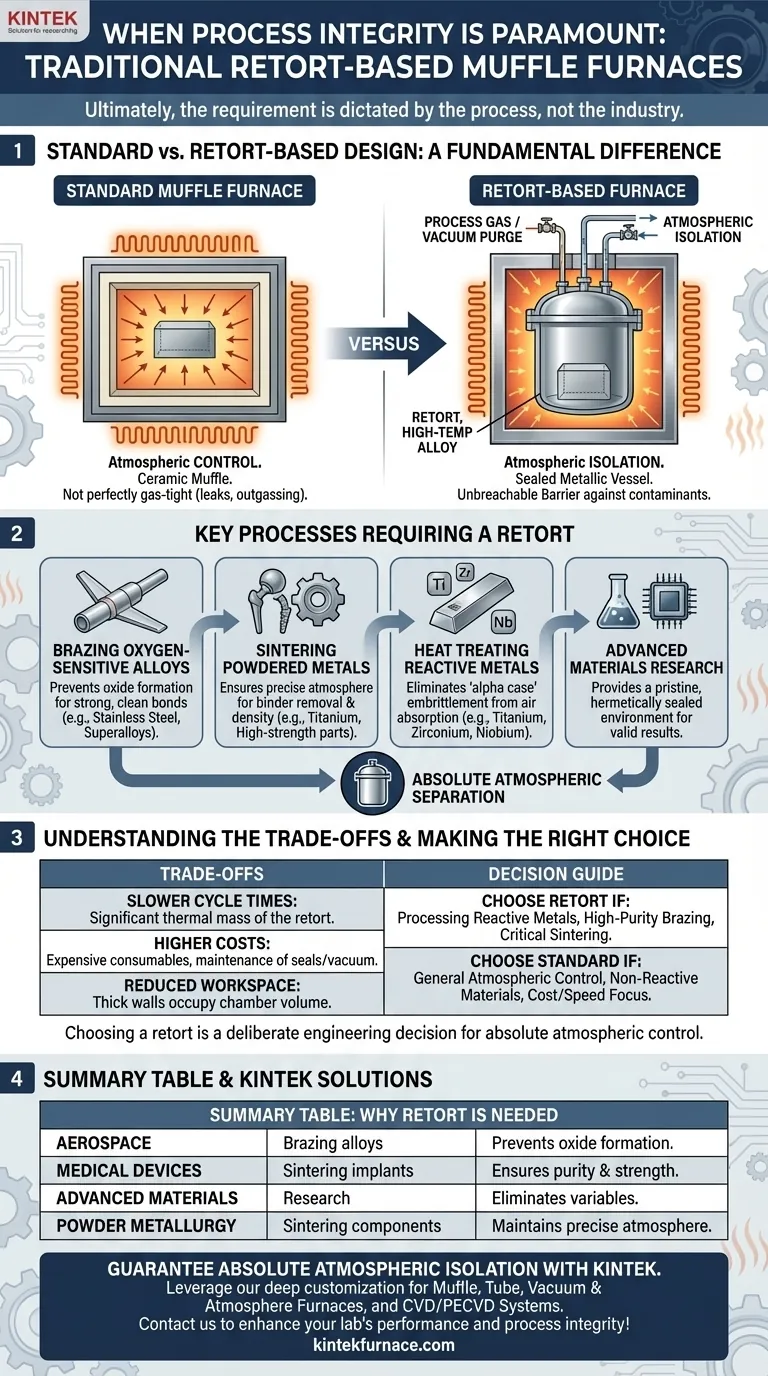

To understand why retorts are still critical, we must first distinguish them from a standard muffle furnace design.

The Standard Muffle Furnace

A standard muffle furnace uses a ceramic chamber (the "muffle") to contain the workload. Heating elements are positioned outside this muffle, heating it radiantly.

While this design protects parts from direct contact with the elements, the ceramic muffle itself is not perfectly gas-tight. Gaskets and door seals can leak, and the insulation materials can outgas contaminants at high temperatures.

The Retort-Based Design: A Sealed Vessel

A retort is a sealed, metallic container—often made from a high-temperature nickel alloy—that is placed inside the furnace's heating chamber.

The workpiece is loaded into the retort, which is then purged and backfilled with a specific process gas (like hydrogen or argon) or evacuated to create a vacuum. The entire sealed vessel is then heated by the furnace.

The Principle of Absolute Separation

The retort creates an unbreachable barrier. It physically separates the process atmosphere inside the retort from the ambient air and potential contaminants within the main furnace chamber.

This is the fundamental difference: a standard muffle furnace offers atmospheric control, while a retort furnace provides atmospheric isolation.

Key Processes Requiring a Retort

Certain high-stakes thermal processes cannot tolerate the slightest contamination, making a retort essential.

Brazing of Oxygen-Sensitive Alloys

Aerospace and defense applications often involve brazing complex components made of stainless steel or superalloys.

Even minuscule amounts of oxygen will form oxides on the part's surface, preventing the braze filler metal from wetting and flowing properly. A retort purged with pure, dry hydrogen or held under a deep vacuum ensures a perfectly clean, oxide-free surface for a strong bond.

Sintering of Powdered Metals

Industries from medical device manufacturing (e.g., titanium hip implants) to automotive (e.g., high-strength gears) use sintering to fuse powdered metals into a solid mass.

This process often requires a specific atmosphere to first burn off polymer binders without oxidizing the fine metal particles. A retort provides the precise control needed to prevent oxidation and ensure the final part meets its density and strength specifications.

Heat Treating of Reactive Metals

Metals like titanium, zirconium, and niobium are highly reactive at elevated temperatures. They act like sponges, readily absorbing oxygen and nitrogen from the air.

This absorption, known as alpha case, creates a brittle outer layer that severely compromises the metal's fatigue life and structural integrity. Processing these materials in a retort backfilled with high-purity argon is non-negotiable.

Advanced Materials Research

When developing new alloys, growing single crystals, or testing material properties, scientists must ensure their results are not skewed by unintended environmental reactions.

A retort provides a pristine, hermetically sealed environment, eliminating atmospheric variables and ensuring the experimental results are valid and repeatable.

Understanding the Trade-offs

While retorts provide unmatched atmospheric purity, they come with practical disadvantages that make them unsuitable for every application.

Slower Cycle Times

The retort itself is a significant thermal mass. The furnace must first heat the heavy alloy retort, which then transfers its heat to the parts inside. This slows down both the heat-up and cool-down portions of the cycle, reducing throughput.

Higher Equipment and Maintenance Costs

High-temperature alloy retorts are expensive consumable items. Repeated thermal cycling induces stress, creep, and oxidation, giving them a finite service life. The seals, gaskets, and vacuum systems also add to the initial cost and ongoing maintenance requirements.

Reduced Usable Workspace

The thick walls of the retort take up valuable space within the furnace's heated chamber. For a given furnace size, a retort-based system will have a smaller working volume than a standard muffle furnace.

Making the Right Choice for Your Goal

The choice between a standard muffle and a retort-based furnace comes down to the sensitivity of your material and the required purity of your process atmosphere.

- If your primary focus is processing reactive metals (e.g., titanium): A retort is non-negotiable to prevent atmospheric contamination and material embrittlement.

- If your primary focus is high-purity brazing or critical powder sintering: A retort is the only way to guarantee the atmospheric integrity required for a successful process.

- If your primary focus is processing non-reactive steels or ceramics with general atmospheric control: A standard muffle furnace with gas-purging capabilities is often sufficient, more cost-effective, and offers faster cycle times.

Choosing a retort is a deliberate engineering decision to achieve absolute atmospheric control when process integrity cannot be compromised.

Summary Table:

| Industry | Key Applications | Why Retort is Needed |

|---|---|---|

| Aerospace | Brazing of oxygen-sensitive alloys | Prevents oxide formation for strong bonds |

| Medical Device Manufacturing | Sintering of powdered metals (e.g., titanium implants) | Ensures purity and strength specifications |

| Advanced Materials Science | Research and development of new alloys | Eliminates environmental variables for valid results |

| Powder Metallurgy | Sintering high-strength components | Maintains precise atmosphere to prevent oxidation |

Need a furnace that guarantees absolute atmospheric isolation for your critical processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're in aerospace, medical device manufacturing, or materials science, we can help you achieve contamination-free results with reliable retort-based designs. Contact us today to discuss how our solutions can enhance your lab's performance and ensure process integrity!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the core function of a high-temperature muffle furnace in silver nanoparticle circuits? Optimize Conductivity

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?