At its core, a vertical tube furnace is a specialized tool used across a range of advanced industries where precise thermal processing is non-negotiable. The most prominent users include materials science and research, nanotechnology, electronics manufacturing, and chemical processing. These fields rely on the furnace's unique vertical orientation to achieve superior temperature uniformity and to manage processes influenced by gravity, such as thin-film deposition and powder treatment.

The decision to use a vertical tube furnace over a horizontal one is not arbitrary. It is a deliberate engineering choice driven by the need for process control, especially when dealing with gravity-sensitive materials or requiring the highest degree of thermal uniformity for consistent, repeatable results.

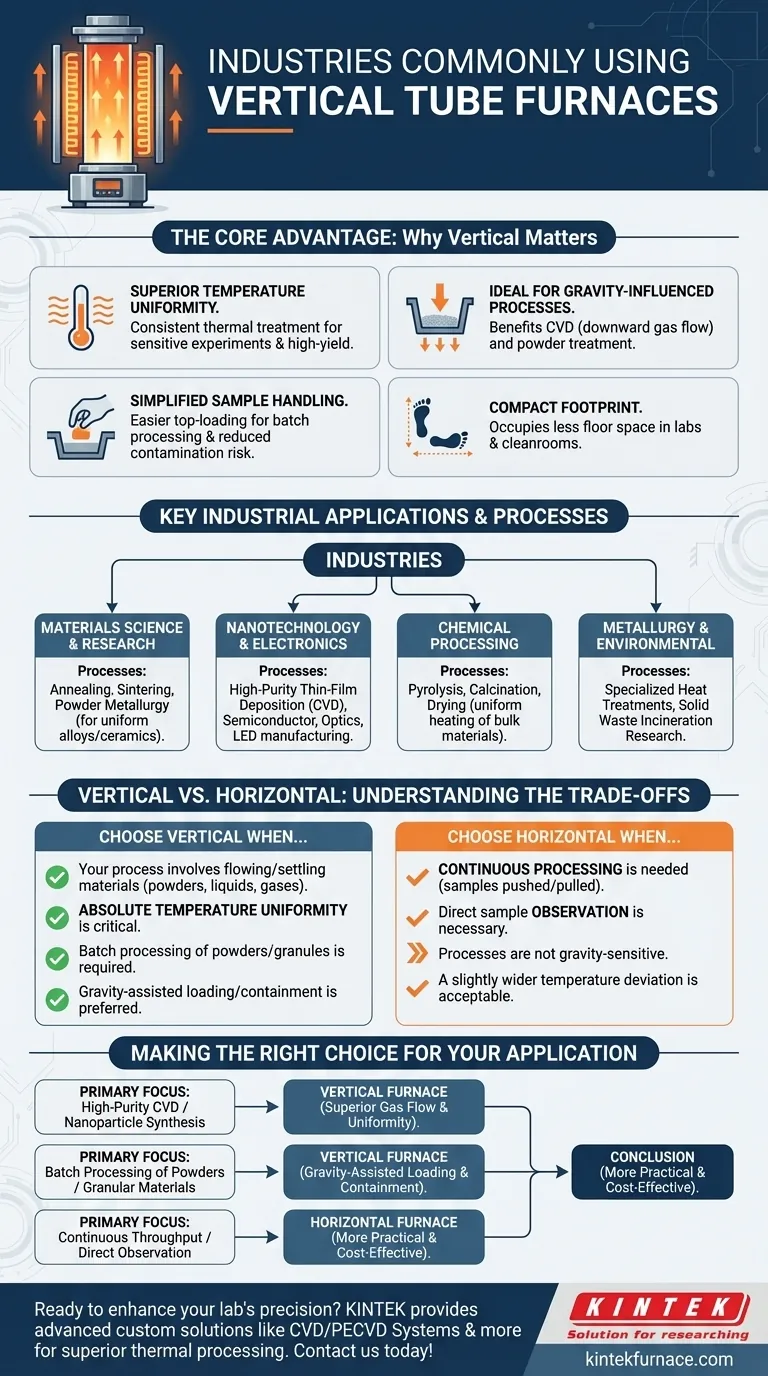

The Core Advantage: Why Vertical Orientation Matters

Understanding the choice of a vertical furnace begins with appreciating the physical advantages of its orientation. The design directly addresses common challenges in high-temperature material processing.

Superior Temperature Uniformity

In a vertical tube, natural convection is more symmetrical. As air or process gas heats, it rises uniformly along the central axis, creating a more stable and even thermal environment compared to a horizontal furnace, where hot gas tends to rise to the top of the tube.

This results in consistent and reliable thermal treatment across the entire sample, which is critical for sensitive experiments and high-yield manufacturing.

Ideal for Gravity-Influenced Processes

Many advanced processes are fundamentally governed by gravity. The vertical orientation leverages this force instead of fighting it.

Processes like Chemical Vapor Deposition (CVD) benefit from a uniform, downward flow of precursor gases over a substrate. Likewise, treating powders or granular materials is far simpler, as gravity keeps them settled at the bottom of a crucible without spillage.

Simplified Sample Handling

Loading and unloading samples, especially powders, granules, or materials within a crucible, is significantly easier in a top-loading vertical furnace.

This simplifies batch processing, reduces the risk of sample contamination or loss, and can improve operational efficiency in a lab or production environment.

Compact Footprint

By building up instead of out, vertical furnaces occupy less floor space. This is a practical and significant advantage in modern laboratories and cleanrooms where every square foot is valuable.

Key Industrial Applications and Processes

The physical advantages of the vertical design translate directly into specific applications where precision is paramount.

Materials Science and Research

This is the broadest field of use. Researchers use vertical furnaces for creating and testing new materials.

Key processes include annealing, which modifies a material's microstructure; sintering, which fuses powders into a solid mass; and powder metallurgy, where uniformity is essential for creating high-performance alloys and ceramics.

Nanotechnology and Electronics

In these fields, control at the atomic level is the goal. Vertical furnaces, particularly CVD furnaces, are workhorses for this industry.

They are used to create the high-purity thin films and coatings that form the basis of semiconductors, optics, and LEDs. The uniform gas flow and temperature control ensure the deposited layers have consistent thickness and properties.

Chemical Processing

The chemical industry uses vertical furnaces for reactions that require contained, uniform heating of bulk materials.

Common applications include pyrolysis (thermal decomposition in an inert atmosphere), calcination (heating solids to drive off impurities or water), and drying of sensitive chemical compounds. The vertical design ensures the entire batch reacts under the same conditions.

Metallurgy and Environmental Applications

In metallurgy, vertical furnaces are used for specialized heat treatments of metal components. For environmental applications, their ability to process bulk materials makes them suitable for research into solid waste incineration and the thermal treatment of contaminants.

Understanding the Trade-offs: Vertical vs. Horizontal

Choosing a furnace is about matching the tool to the task. A vertical furnace is not always the best choice.

When to Choose Vertical

A vertical furnace excels when your process involves materials that flow or settle, such as powders, liquids, or gases in a CVD process. It is the superior choice when absolute temperature uniformity is the most critical variable for achieving your desired outcome.

When a Horizontal Furnace Is a Better Fit

Horizontal tube furnaces are often preferred for continuous processing, where samples are pushed or pulled through the heating zone. They also allow for easier direct observation of the sample during the heating cycle. For processes that are not sensitive to gravity and where a slightly wider temperature deviation is acceptable, a horizontal furnace can be a simpler and more cost-effective solution.

Making the Right Choice for Your Application

To select the correct furnace, you must first define your primary process goal.

- If your primary focus is high-purity film deposition (CVD) or nanoparticle synthesis: A vertical furnace offers the superior gas flow dynamics and thermal uniformity required for these sensitive applications.

- If your primary focus is batch processing of powders or granular materials: The gravity-assisted loading, containment, and even heating of a vertical furnace make it the ideal choice.

- If your primary focus is continuous throughput or direct sample observation: A horizontal furnace is likely more practical and better suited to your workflow.

Ultimately, your choice is dictated by the physics of your process and the level of precision your material demands.

Summary Table:

| Industry | Key Applications |

|---|---|

| Materials Science & Research | Annealing, sintering, powder metallurgy |

| Nanotechnology & Electronics | Thin-film deposition (CVD), semiconductor manufacturing |

| Chemical Processing | Pyrolysis, calcination, drying |

| Metallurgy & Environmental | Heat treatments, solid waste incineration |

Ready to enhance your lab's precision with a custom vertical tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met for superior thermal processing. Contact us today to discuss how we can support your industry application!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety