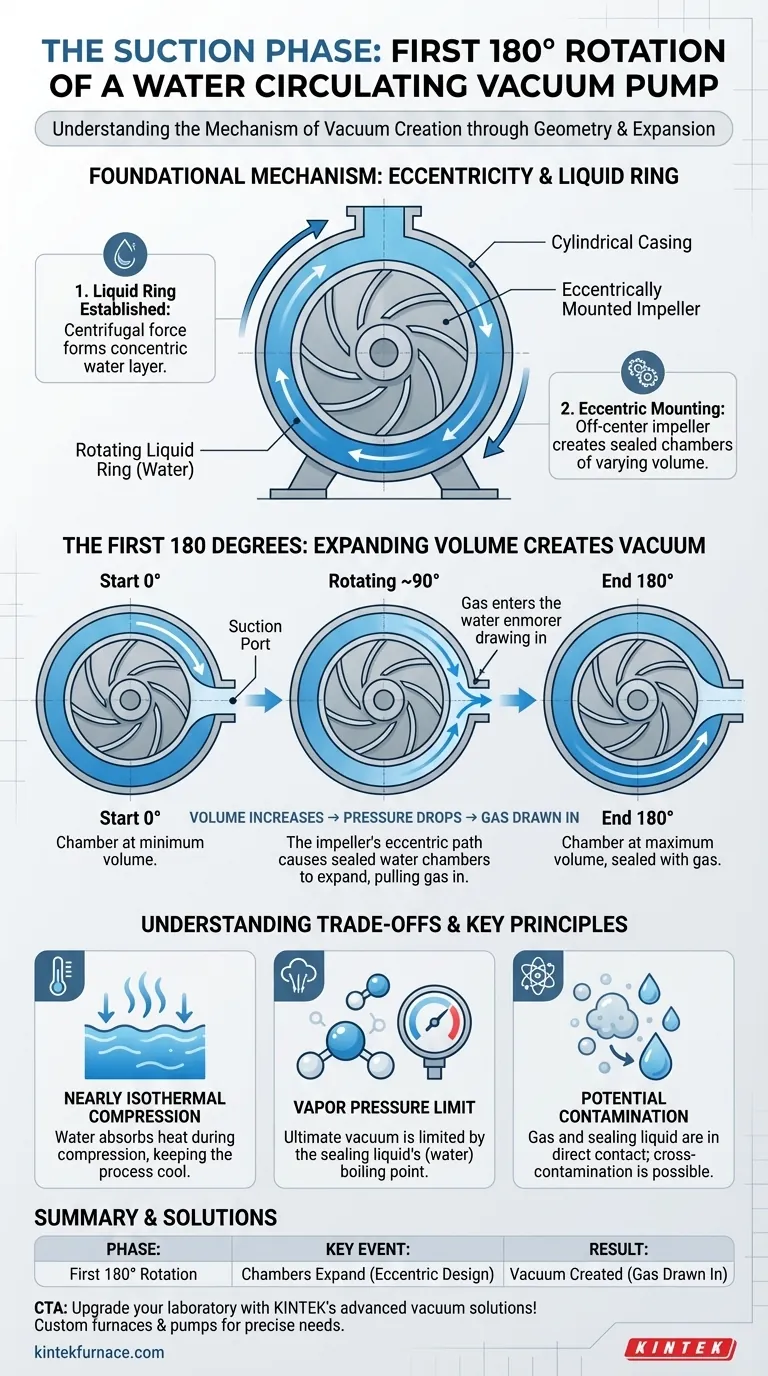

During the first 180-degree rotation of a water circulating vacuum pump's impeller, the primary event is the creation of a vacuum by drawing gas into the pump. As the impeller turns, chambers formed between its blades and a ring of water progressively expand in volume. This expansion lowers the pressure inside the chambers, pulling gas in through the suction port.

The core principle is not just rotation, but geometry. The impeller is mounted off-center within the casing, causing sealed pockets of water to expand and then contract, which creates the suction and compression needed to function as a vacuum pump.

The Foundational Mechanism: Eccentricity and the Liquid Ring

To understand the suction phase, you must first grasp how the pump is constructed. The entire operation hinges on a clever and robust mechanical design.

Establishing the Liquid Ring

When the pump starts, centrifugal force throws the working fluid—typically water—against the inner wall of the pump's cylindrical casing. This creates a stable, rotating ring of liquid that is concentric with the casing itself.

The Critical Role of Eccentric Mounting

The impeller is installed eccentrically (off-center) inside the casing.

This means the hub of the impeller is very close to the liquid ring at one point (bottom) and furthest away at the opposite point (top). This variation in distance is the key to the pump's function.

Forming the Pumping Chambers

The blades of the impeller divide the crescent-shaped space between the impeller hub and the inner surface of the liquid ring. This creates a series of small, individual chambers that are sealed by the water.

The Suction Phase: The First 180 Degrees

With the core components established, we can now analyze the first half of the impeller's rotation, which is dedicated entirely to suction.

Expanding Volume Creates Vacuum

As a chamber rotates through the first 180 degrees (moving from the point of nearest approach to the point of furthest approach), its volume steadily increases. This is because the inner wall of the water ring is moving further away from the impeller hub.

This expansion of a sealed volume causes a significant drop in pressure, creating a vacuum within that chamber.

Drawing Gas from the Suction Port

The suction port of the pump is strategically located in this first half of the rotation. The low-pressure chambers pass by the port, and the higher-pressure gas from the system you are evacuating is drawn into these expanding chambers.

Isolation from the Suction Port

As each chamber reaches the 180-degree mark, it achieves its maximum volume and is filled with the drawn-in gas. At this point, it rotates past the suction port, effectively sealing the captured gas inside.

Understanding the Trade-offs

Liquid ring vacuum pumps are valued for their simplicity and reliability, but it is important to understand their operational characteristics and limitations.

Nearly Isothermal Compression

The large volume of water acts as an excellent heat sink. It absorbs the heat generated during the subsequent compression of the gas, making the process nearly isothermal (constant temperature). This is a major advantage when handling sensitive or potentially explosive gases.

The Sealing Fluid is Key

The ultimate vacuum a liquid ring pump can achieve is limited by the vapor pressure of its sealing liquid. If you are using water, the pump cannot create a vacuum lower than the pressure at which water begins to boil at its current temperature.

Potential for Contamination

The gas being pumped is in direct contact with the sealing liquid. This means the liquid can become contaminated by the gas, and conversely, the exhausted gas will contain vapor from the sealing liquid.

Key Principles for Understanding Operation

To apply this knowledge, focus on how the core principles affect performance and application.

- If your primary focus is vacuum creation: The key is the expanding volume of the sealed water chambers during the first 180 degrees of rotation, which is timed to align with the suction port.

- If your primary focus is the overall mechanism: The eccentric mounting of the impeller within the static liquid ring is the fundamental design element that enables the entire suction and compression cycle.

- If your primary focus is performance: The temperature and type of sealing liquid are critical, as its vapor pressure directly limits the pump's ultimate achievable vacuum.

Understanding this elegant cycle of expansion and compression empowers you to diagnose issues and appreciate the robust design of the liquid ring pump.

Summary Table:

| Phase | Key Event | Result |

|---|---|---|

| First 180° Rotation | Impeller turns, chambers expand due to eccentric mounting | Pressure drops, gas is drawn in through suction port |

| Key Principle | Eccentric impeller design with liquid ring | Enables suction and compression cycle for vacuum creation |

| Limitation | Vapor pressure of sealing liquid (e.g., water) | Limits ultimate vacuum achievable |

Upgrade your laboratory with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our vacuum pumps and furnaces can optimize your processes!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What is the function of a laboratory electric blast drying oven in biomass pretreatment? Standardize Your Samples

- What roles do high-purity graphite molds perform in A357 sintering? Enhancing Aluminum Matrix Composite Performance

- Why is the selection of crucibles with specific internal linings necessary? Protect Purity in Superalloy Melting

- How does an infrared pyrometer facilitate the precise control of temperatures during microwave-assisted metal recovery?

- Why are quartz tubes suitable for material research applications? Ensure Purity and Precision in High-Temp Experiments

- What precautions should be taken when using the alumina furnace tube for the first time? Ensure Safe Initial Use with Proper Conditioning

- How does the integration of digital control panels and safety devices enhance industrial electric furnace operation?

- What are the limitations of ultra-pure alumina porcelain tubes? Manage Brittleness for Reliable High-Temp Use