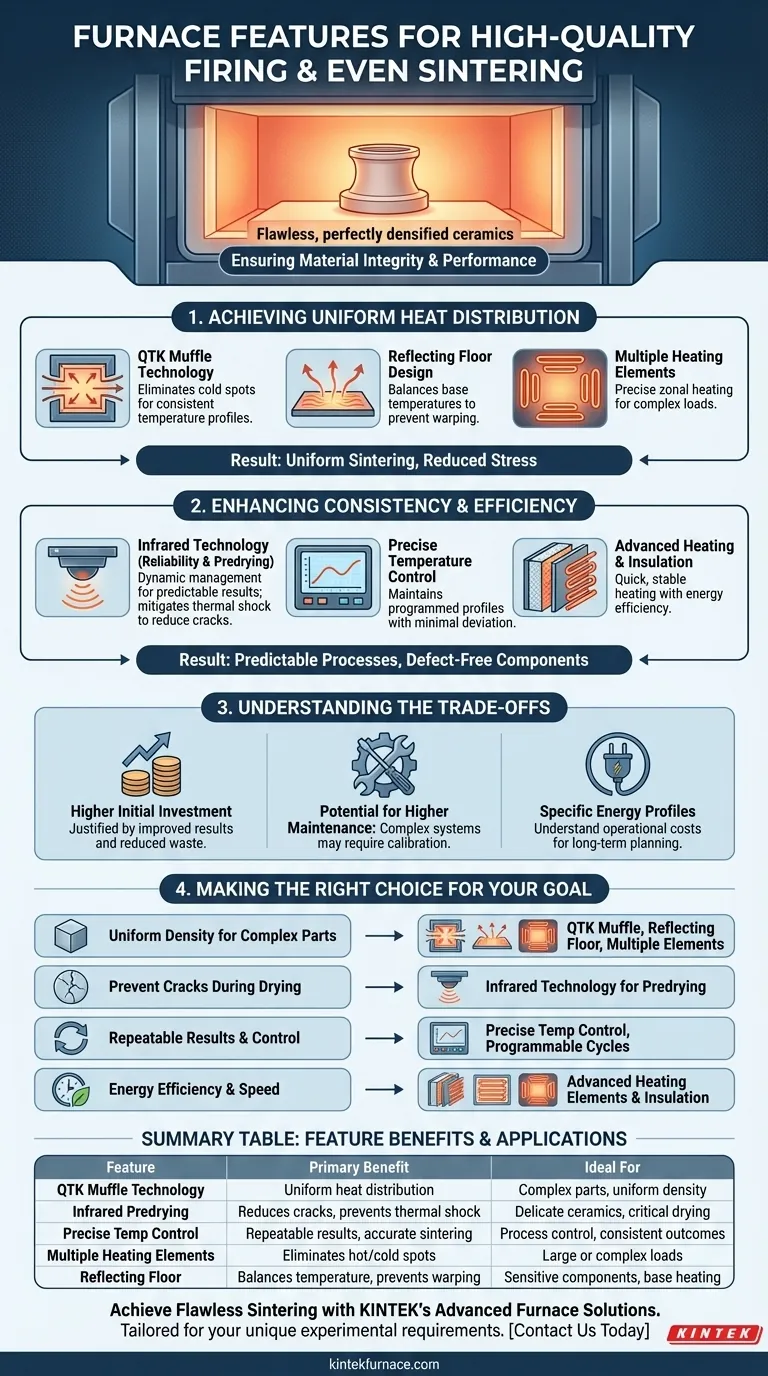

High-quality firing and even sintering in a furnace are primarily ensured by technologies that promote uniform heat distribution, precise thermal management, and controlled atmospheric conditions. Key features include advanced muffle designs, reflective elements, infrared technology for predrying, precise temperature controls, and programmable firing cycles.

Achieving high-quality firing and even sintering is critical for material integrity and performance. The most effective furnaces integrate design elements and technologies that precisely manage heat distribution, prevent thermal shock, and ensure consistency across the entire firing chamber, leading to defect-free and uniformly densified components.

Achieving Uniform Heat Distribution

Consistent heat across the firing chamber is fundamental for even sintering. Without it, parts can experience differential shrinkage or property variations.

QTK Muffle Technology

QTK muffle technology is designed to provide uniform heat distribution within the furnace chamber. This specific muffle design helps to eliminate cold spots and ensure that all parts are exposed to the same temperature profile. The result is more consistent sintering outcomes and reduced material stress.

Reflecting Floor Design

A reflecting floor within the furnace chamber further aids in heat distribution. By reflecting thermal energy, it helps to balance temperatures, particularly at the base of the firing space. This prevents temperature gradients that can lead to uneven sintering or warping of delicate components.

Multiple Heating Elements

Furnaces equipped with multiple heating elements can achieve more even heat distribution. Strategically placed elements allow for precise zonal heating and prevent localized temperature variations. This is crucial for large or complex loads where a single heating source might create hot and cold spots.

Enhancing Firing Consistency and Efficiency

Beyond static heat distribution, dynamic control and efficiency features significantly impact the quality of the firing process.

Infrared Technology for Reliability

Built-in infrared technology offers more reliable firing results and increased efficiency. This technology monitors and manages temperature more dynamically, adapting to the specific material being processed. It contributes to a more predictable and consistent firing process.

Infrared for Predrying

Specifically, infrared technology used during the predrying process helps reduce the risk of cracks. As the furnace closes, rapid temperature changes can induce stress. Infrared assistance in predrying mitigates this thermal shock, preventing structural damage in ceramics.

Precise Temperature Control

Precise temperature control is paramount for high-quality sintering. Advanced control systems maintain the programmed temperature profile with minimal deviation. This accuracy ensures that the material undergoes the correct phase transformations and densification without overheating or underheating.

Advanced Heating Elements & Insulation

The combination of advanced heating elements and superior insulation contributes to both efficiency and stability. Efficient heating elements reach target temperatures quickly and maintain them stably, while superior insulation minimizes heat loss. This partnership ensures energy efficiency and a consistent thermal environment.

Understanding the Trade-offs

While these features enhance quality, they often come with considerations regarding cost, complexity, and maintenance.

Increased Initial Investment

Furnaces with advanced features like QTK muffle technology or integrated infrared systems typically have a higher upfront cost. This investment is often justified by improved results and reduced material waste, but it's a factor in procurement.

Potential for Higher Maintenance

More complex systems with multiple heating zones or specialized sensors might require more sophisticated maintenance. Regular calibration and upkeep are essential to ensure these advanced features continue to perform optimally.

Energy Consumption for Specific Technologies

While overall efficiency is improved, certain advanced heating methods might have specific energy consumption profiles. Understanding the operational costs associated with these technologies is important for long-term planning.

Making the Right Choice for Your Goal

Selecting a furnace involves prioritizing features based on your specific material and production requirements.

- If your primary focus is uniform density across complex parts: Prioritize furnaces with QTK muffle technology, reflecting floors, and multiple heating elements.

- If your primary focus is preventing cracks during critical drying stages: Look for furnaces incorporating infrared technology specifically for predrying.

- If your primary focus is repeatable results and process control: Ensure the furnace has precise temperature control and programmable firing cycles.

- If your primary focus is energy efficiency and speed: Consider furnaces with advanced heating elements and superior insulation.

The integration of these specialized features is what truly distinguishes a high-performance furnace, leading to consistently superior firing and sintering outcomes.

Summary Table:

| Feature | Primary Benefit | Ideal For |

|---|---|---|

| QTK Muffle Technology | Uniform heat distribution | Complex parts, uniform density |

| Infrared Predrying | Reduces cracks, prevents thermal shock | Delicate ceramics, critical drying stages |

| Precise Temperature Control | Repeatable results, accurate sintering | Process control, consistent outcomes |

| Multiple Heating Elements | Eliminates hot/cold spots | Large or complex loads |

| Reflecting Floor | Balances temperature, prevents warping | Sensitive components, base heating |

Achieve flawless sintering and high-quality firing with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Whether you need uniform density for complex parts or crack prevention during drying, KINTEK can tailor a solution for you. Contact us today to discuss how our technologies can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis