Rotary furnaces are engineered for fuel flexibility, and the choice of energy source is a critical operational decision, not a fixed characteristic. The most common fuels used are natural gas, propane, diesel (fuel oil), and electricity, with the selection depending heavily on the furnace's specific design, the material being processed, and economic considerations.

The question is not simply what fuel a rotary furnace can use, but what fuel it should use. The optimal choice always involves a calculated trade-off between operational cost, required temperature precision, and environmental impact for a specific application.

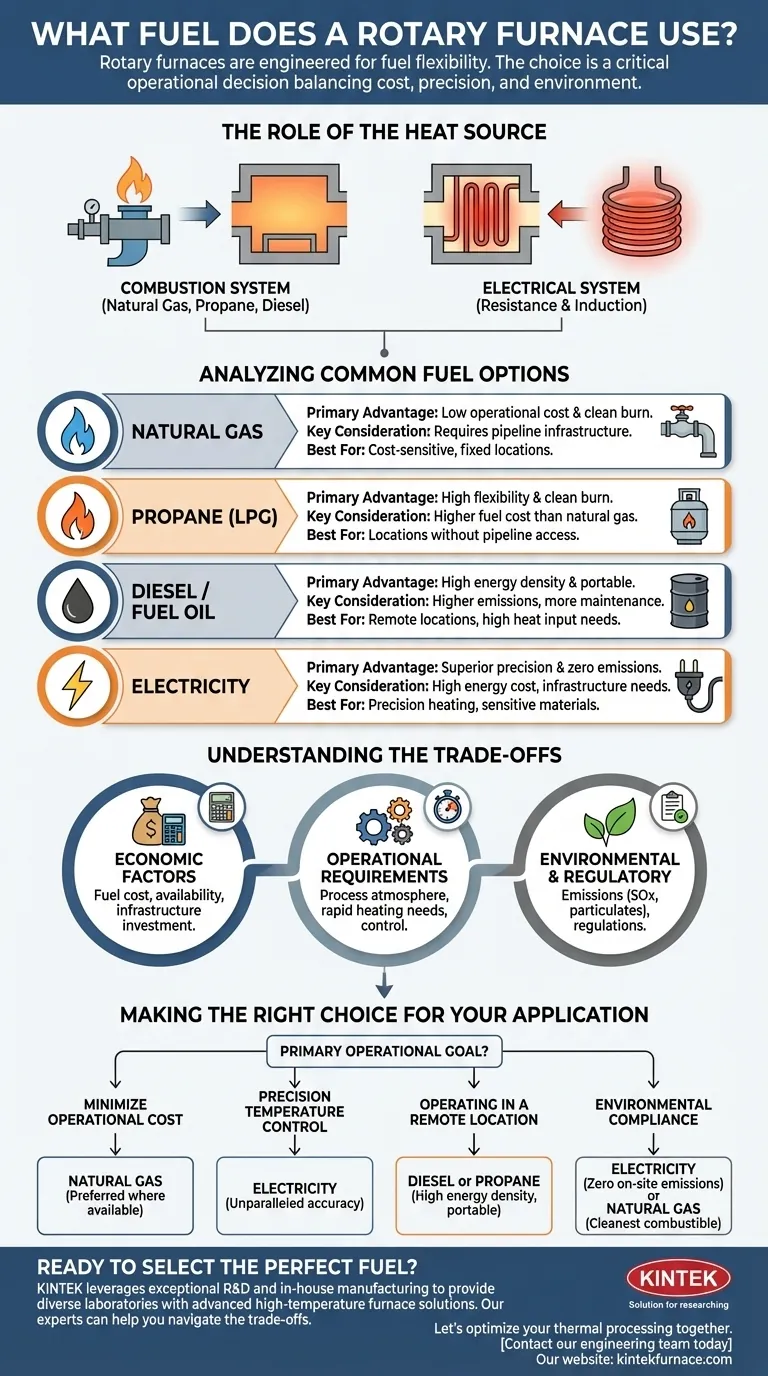

The Role of the Heat Source

A rotary furnace's effectiveness is defined by its ability to deliver controlled thermal energy. This is managed by the internal heat source, which converts fuel into usable heat.

The Combustion System

For fuel-fired furnaces, the heart of the heat source is the burner system. This component atomizes and mixes the fuel (gas or liquid) with air and ignites it, projecting a controlled flame into the furnace chamber to heat the material directly or indirectly.

The Electrical System

In electrically heated furnaces, the "fuel" is electricity. This energy is converted to heat through either resistance elements lining the furnace or via induction. This approach eliminates combustion byproducts, offering a cleaner processing environment.

Analyzing the Common Fuel Options

Each fuel type presents a distinct profile of benefits and drawbacks. The decision hinges on which attributes are most critical for your process.

Natural Gas

Natural gas is often the default choice due to its balance of cost and performance. It burns cleanly compared to liquid fuels and is typically the most cost-effective option where pipeline infrastructure exists.

Propane (LPG)

Propane serves as an excellent alternative when natural gas is unavailable. It shares the clean-burning characteristics of natural gas but is stored on-site in tanks, offering operational flexibility at a generally higher fuel cost.

Diesel / Fuel Oil

These liquid fuels are valued for their high energy density and portability, making them suitable for remote locations or applications requiring very high heat input. However, they produce more emissions and may require more frequent burner maintenance.

Electricity

Electricity provides the highest level of precision and control. By eliminating combustion, it creates the cleanest possible heating environment, which is critical for sensitive materials. This control comes at the cost of higher energy prices and significant electrical infrastructure requirements.

Understanding the Trade-offs

Choosing a fuel is an exercise in balancing competing priorities. There is no single "best" option, only the most appropriate one for a given set of circumstances.

Economic Factors

This is the most common starting point. You must evaluate the per-unit cost of the fuel, its local availability, and the capital investment required for storage and delivery infrastructure (e.g., gas pipelines vs. oil tanks vs. high-capacity electrical service).

Operational Requirements

The process itself dictates fuel choice. Does the material require a specific atmospheric condition, free from combustion byproducts? Is rapid heating necessary? Electrical heating excels at control, while fossil fuels often provide faster, high-volume heat input.

Environmental and Regulatory Compliance

Emissions are an increasingly critical factor. Electrical heating produces zero on-site emissions. Among fossil fuels, natural gas is the cleanest, while fuel oil produces higher levels of pollutants like sulfur oxides (SOx) and particulates that may be subject to stricter environmental regulations.

Making the Right Choice for Your Application

Your final decision should be guided by your primary operational goal.

- If your primary focus is minimizing operational cost: Natural gas is almost always the preferred choice where available, due to its low unit price and clean burn.

- If your primary focus is precision temperature control: Electricity offers unparalleled accuracy and a perfectly clean atmosphere, making it essential for high-value or sensitive materials.

- If your primary focus is operating in a remote location: Diesel or propane provide high energy density and are not dependent on fixed infrastructure, ensuring operational continuity.

- If your primary focus is environmental compliance: Electricity is the clear winner for zero on-site emissions, with natural gas being the best-in-class option among combustible fuels.

Ultimately, selecting the right fuel is about aligning the furnace's energy source with your specific process goals and economic realities.

Summary Table:

| Fuel Type | Primary Advantage | Key Consideration | Best For |

|---|---|---|---|

| Natural Gas | Low operational cost | Requires pipeline infrastructure | Cost-sensitive, fixed-location operations |

| Propane (LPG) | High flexibility, clean burn | Higher fuel cost than natural gas | Locations without natural gas access |

| Diesel / Fuel Oil | High energy density, portable | Higher emissions, more maintenance | Remote locations, high heat input needs |

| Electricity | Superior control, zero emissions | High energy cost, infrastructure needs | Precision heating, sensitive materials |

Ready to Select the Perfect Fuel for Your Rotary Furnace?

Choosing the right energy source is critical for the efficiency, cost, and quality of your thermal process. KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions.

Our experts can help you navigate the trade-offs between natural gas, propane, diesel, and electricity. We offer a comprehensive product line—including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, and more—complemented by strong deep customization capability to precisely meet your unique experimental and production requirements.

Let's optimize your thermal processing together. Contact our engineering team today for a personalized consultation.

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs