Selecting the right inert atmosphere furnace is about controlling the unseen variables that can compromise your work. The most critical features are those that create, maintain, and verify a stable, oxygen-free environment. This is achieved through a combination of a hermetically sealed chamber, a precise gas management system, and integrated sensors that provide real-time data on the atmospheric conditions.

An inert atmosphere furnace is not just a hot box you fill with nitrogen. It is an integrated system designed to systematically displace, monitor, and prevent the ingress of oxygen and moisture, ensuring the chemical integrity of your material throughout the entire thermal cycle.

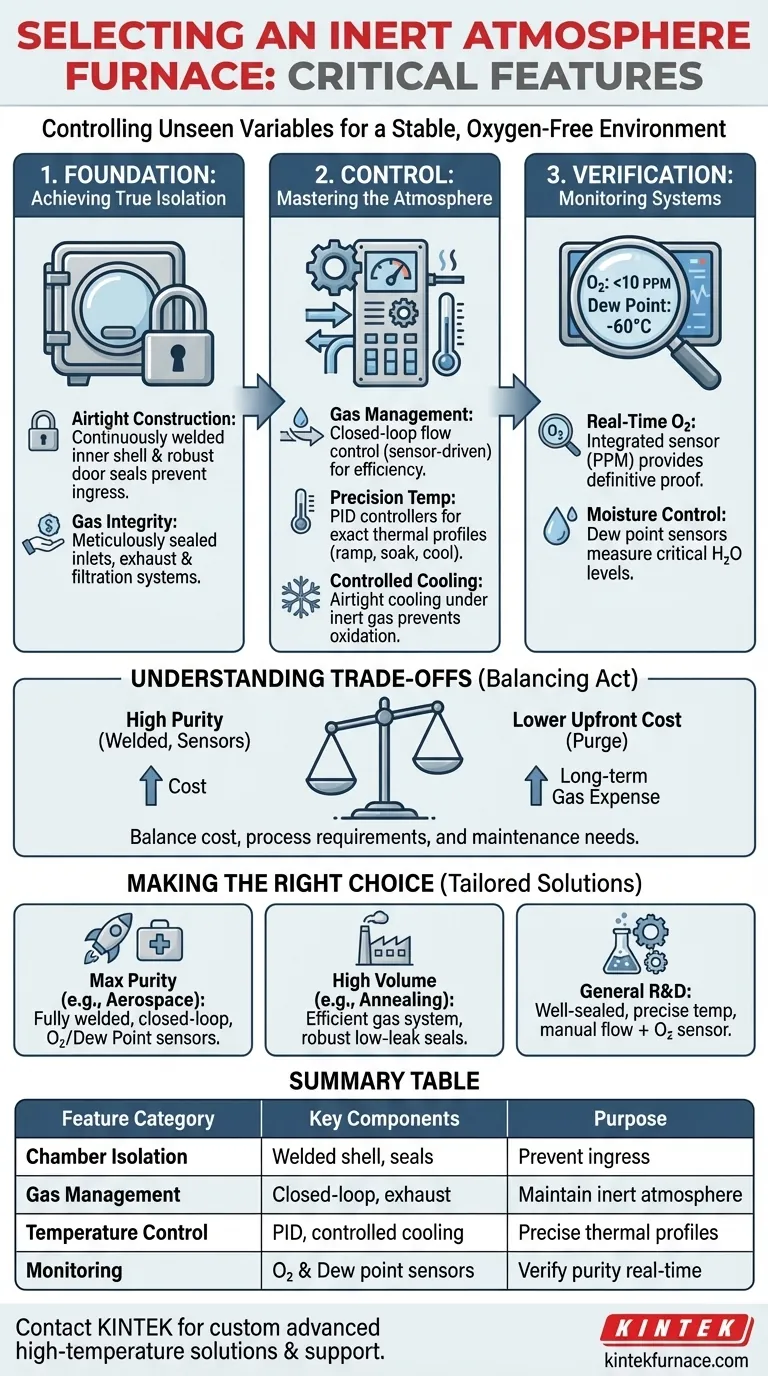

The Foundation: Achieving True Isolation

The entire principle of an inert atmosphere relies on isolating the interior environment from the outside air. Any failure here undermines all other features.

Airtight Chamber Construction

A truly inert environment starts with the physical barrier. The highest-quality furnaces feature a continuously welded inner shell, which eliminates the countless potential leak paths found in bolted or riveted designs. Door seals are equally critical, requiring robust gaskets and strong clamping mechanisms to prevent ingress during operation.

Gas Inlet and Exhaust Integrity

Every point where something enters or leaves the chamber is a potential vulnerability. The gas supply system, thermocouple ports, and exhaust vents must be meticulously sealed. A proper exhaust and filtration system is also necessary to safely vent displaced gases without creating backpressure that could compromise the seals.

Mastering the Atmosphere: Active Control Systems

Once the chamber is sealed, you need active systems to create and maintain the desired conditions. This goes far beyond simply pumping in inert gas.

The Gas Management System

A basic system uses a constant, high-volume flow of inert gas (like nitrogen or argon) to purge oxygen. A more advanced and efficient approach is a closed-loop flow control system. This system uses sensors to actively monitor the atmosphere and injects just enough gas to maintain the setpoint, significantly reducing gas consumption and operating costs.

Precision Temperature Control

Inert atmospheres are often required for processes like annealing or sintering that demand exact temperature profiles. A sophisticated PID (Proportional-Integral-Derivative) controller is essential for accurately ramping, soaking, and cooling according to your specifications, preventing thermal shock and ensuring material properties are met.

Controlled Cooling

Preventing oxidation during heating is only half the battle. If the product is exposed to air while it is still hot, surface oxidation will occur instantly. An airtight cooling system or the ability to cool under a continuous inert gas blanket is crucial to maintain the bright, clean finish achieved during the heating cycle.

Verification, Not Assumption: The Monitoring Systems

You cannot control what you cannot measure. Assuming the atmosphere is inert because you are flowing gas into it is a common and costly mistake.

Real-Time Oxygen Monitoring

An integrated oxygen sensor is the single most important verification tool. It provides a definitive, real-time measurement (often in parts-per-million, or PPM) of the oxygen level inside the chamber. This data is your proof that the desired inert atmosphere has been achieved and is being maintained.

Controlling Moisture with Dew Point Sensors

Moisture (H₂O) is another critical contaminant, as it can be a source of oxygen at high temperatures and cause unwanted reactions. A dew point sensor measures the moisture content of the gas. For applications requiring an extremely dry environment, this monitoring is just as important as measuring oxygen.

Understanding the Trade-offs

Selecting these features involves balancing cost, process requirements, and operational complexity.

Cost vs. Purity

A furnace with a fully welded shell, closed-loop gas control, and integrated O₂/dew point sensors provides the highest level of purity and control. However, it comes at a significant upfront cost. A simpler system with constant gas purging is less expensive to purchase but will have much higher long-term gas consumption costs and less process certainty.

Process Specificity

The stringency of your requirements dictates the necessary features. A basic bright annealing process may only need a well-sealed chamber and a reliable nitrogen purge. Sintering advanced medical-grade ceramics, however, will likely demand active PPM oxygen monitoring and strict dew point control to avoid any impurities.

Maintenance and Consumables

Advanced systems require more maintenance. Oxygen sensors need periodic calibration or replacement, door seals wear out, and inert gas is a continuous operational expense. These long-term costs must be factored into the initial purchasing decision.

Making the Right Choice for Your Process

Your decision should be driven by the sensitivity of your material and the required purity of the final product.

- If your primary focus is maximum purity for sensitive materials (e.g., aerospace, medical): Prioritize a fully welded, closed-loop system with integrated oxygen and dew point sensors for verifiable control.

- If your primary focus is high-volume production with consistent quality (e.g., bright annealing): Focus on a reliable and efficient gas management system and robust, low-leak door seals to control gas consumption costs.

- If your primary focus is general-purpose R&D or heat treating: A well-sealed chamber with precise temperature control and manual gas flow may be sufficient, but an oxygen sensor is always a highly recommended addition.

Ultimately, the best furnace is the one that provides verifiable and repeatable control over the specific atmospheric variables that threaten your process.

Summary Table:

| Feature Category | Key Components | Purpose |

|---|---|---|

| Chamber Isolation | Welded inner shell, robust door seals | Prevent oxygen and moisture ingress |

| Gas Management | Closed-loop flow control, exhaust system | Maintain inert atmosphere efficiently |

| Temperature Control | PID controllers, controlled cooling | Ensure precise thermal profiles |

| Monitoring Systems | Oxygen sensors, dew point sensors | Verify atmosphere purity in real-time |

Ready to enhance your lab's capabilities with a custom inert atmosphere furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique experimental needs, improving purity, efficiency, and repeatability. Contact us today to discuss how we can support your process!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process