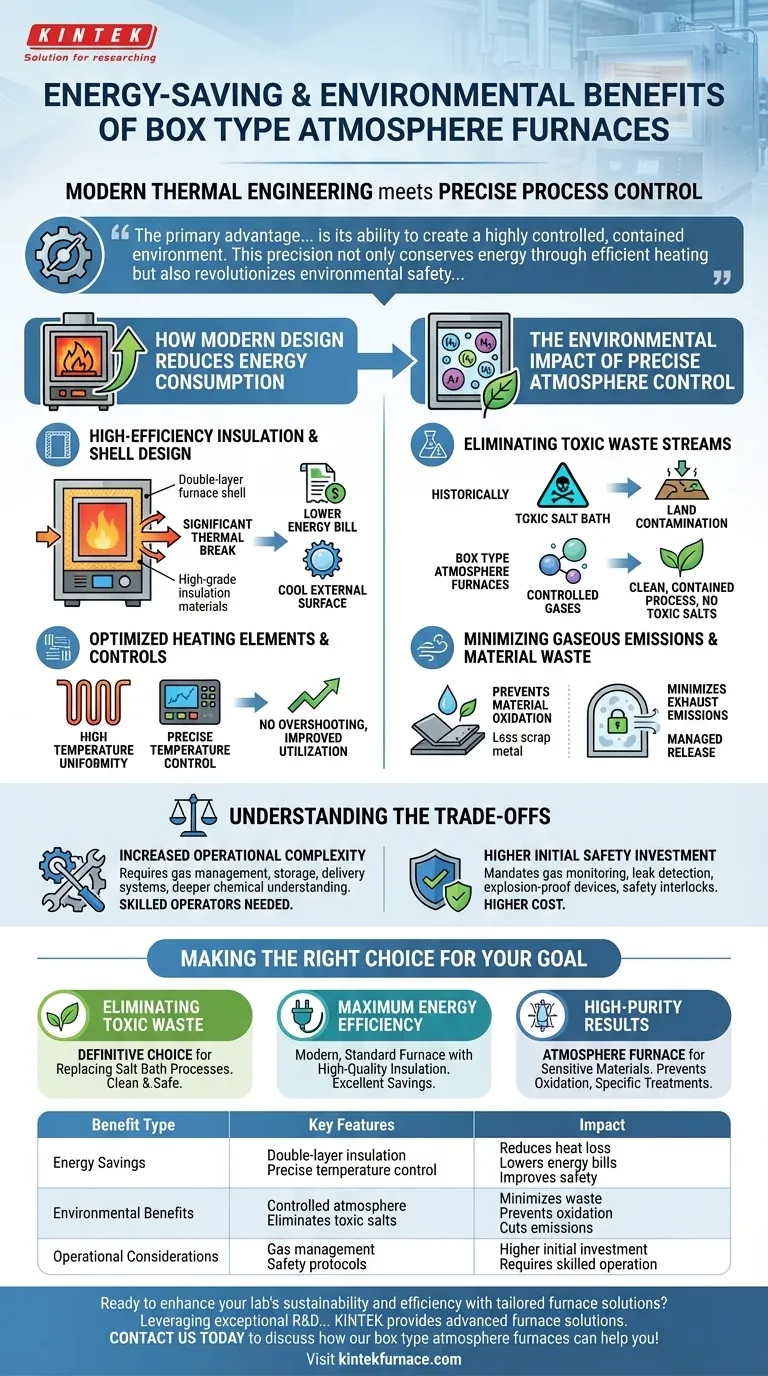

At their core, box type atmosphere furnaces deliver significant energy and environmental benefits by combining modern thermal engineering with precise process control. Their designs feature advanced insulation and efficient heating elements to drastically reduce energy consumption, while the ability to manage the internal atmosphere eliminates the need for older, toxic chemical processes and minimizes material waste.

The primary advantage of a box type atmosphere furnace is its ability to create a highly controlled, contained environment. This precision not only conserves energy through efficient heating but also revolutionizes environmental safety by replacing hazardous waste streams with clean, manageable processes.

How Modern Design Reduces Energy Consumption

The energy efficiency of a modern box type atmosphere furnace stems from a systematic approach to minimizing heat loss and optimizing energy delivery. It is a direct result of superior materials and intelligent control systems.

High-Efficiency Insulation and Shell Design

A key feature is the double-layer furnace shell. This design, combined with high-grade insulation materials, creates a significant thermal break between the internal chamber and the external environment.

This construction drastically reduces heat loss to the surrounding area. It not only lowers energy bills but also results in a cooler external surface, improving operator safety and reducing the air conditioning load on the facility.

Optimized Heating Elements and Controls

These furnaces utilize advanced resistance wire heating elements and sophisticated control systems. The layout of these elements is optimized to ensure high temperature uniformity throughout the chamber.

More importantly, precise temperature control prevents overshooting the target temperature, a common source of wasted energy. This level of control ensures energy is used only when and where it is needed, directly improving energy utilization and process repeatability.

The Environmental Impact of Precise Atmosphere Control

The most profound environmental benefits are derived from the furnace's ability to maintain a specific, controlled atmosphere of gases like nitrogen, hydrogen, or argon. This capability fundamentally changes the nature of the heat treatment process.

Eliminating Toxic Waste Streams

Historically, processes like carburizing or preventing oxidation relied on toxic salt baths, often containing cyanides. This created significant environmental hazards, including land contamination and extreme difficulty in disposing of waste salts and contaminated equipment.

Box type atmosphere furnaces completely eliminate these problems. By using controlled gases to achieve the desired surface chemistry or prevent oxidation, they replace a hazardous, multi-stage chemical process with a clean, contained, and highly manageable physical one. There are no toxic salts, contaminated jigs, or pack carburizing waste to dispose of.

Minimizing Gaseous Emissions and Material Waste

The protective atmosphere prevents material oxidation during high-temperature processing. This directly reduces the amount of scrapped or reworked parts that fail to meet quality specifications due to surface defects.

Furthermore, precise atmosphere control minimizes exhaust emissions. By managing the process within a sealed chamber, the release of volatile compounds or reaction byproducts is contained and can be managed effectively, unlike open-air or less-controlled methods.

Understanding the Trade-offs

While highly beneficial, adopting atmosphere furnace technology involves acknowledging a shift in operational requirements. It is not a simple drop-in replacement for a basic air furnace.

Increased Operational Complexity

Unlike a standard box furnace operating in natural air, an atmosphere furnace requires the management of specific gases. This includes gas storage, delivery systems, and a deeper understanding of the process chemistry.

Operators must be trained to handle potentially flammable or explosive gases like hydrogen. This necessitates a higher level of skill and adherence to strict operational protocols.

Higher Initial Safety Investment

The use of specialized gases mandates a higher safety threshold. Systems must be equipped with gas monitoring, leak detection, and explosion-proof devices.

Safety interlocks that manage power failures, overheating, and thermocouple breaks are standard, but the gas management system adds another layer of required safety engineering. The initial investment is therefore higher than that of a simple furnace.

Making the Right Choice for Your Goal

Selecting the right furnace requires aligning the technology's capabilities with your primary operational driver.

- If your primary focus is eliminating toxic waste: A box type atmosphere furnace is the definitive choice for replacing salt bath processes, offering a vastly cleaner and safer operational environment.

- If your primary focus is maximum energy efficiency for non-reactive parts: A modern, standard (non-atmosphere) box furnace with high-quality insulation will provide excellent energy savings without the complexity of gas management.

- If your primary focus is high-purity results for sensitive materials: The precise control offered by an atmosphere furnace is non-negotiable for preventing oxidation and achieving specific surface treatments in electronics, aerospace, or materials research.

Ultimately, investing in a box type atmosphere furnace is a strategic decision to enhance process control, improve product quality, and operate in a more environmentally responsible manner.

Summary Table:

| Benefit Type | Key Features | Impact |

|---|---|---|

| Energy Savings | Double-layer insulation, precise temperature control | Reduces heat loss, lowers energy bills, improves safety |

| Environmental Benefits | Controlled atmosphere (e.g., nitrogen, hydrogen), eliminates toxic salts | Minimizes waste, prevents oxidation, cuts emissions |

| Operational Considerations | Gas management, safety protocols | Higher initial investment, requires skilled operation |

Ready to enhance your lab's sustainability and efficiency with tailored furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our box type atmosphere furnaces can help you achieve superior energy savings and environmental benefits!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment