In the world of thermal engineering, stainless steel sheaths are the ubiquitous choice for encasing electric heating elements. They are found in applications ranging from common household water heaters and kitchen appliances to demanding industrial processes involving air, oils, and process solutions. This widespread use is due to their exceptional balance of high mechanical strength, excellent heat transfer, strong corrosion resistance, and overall cost-effectiveness.

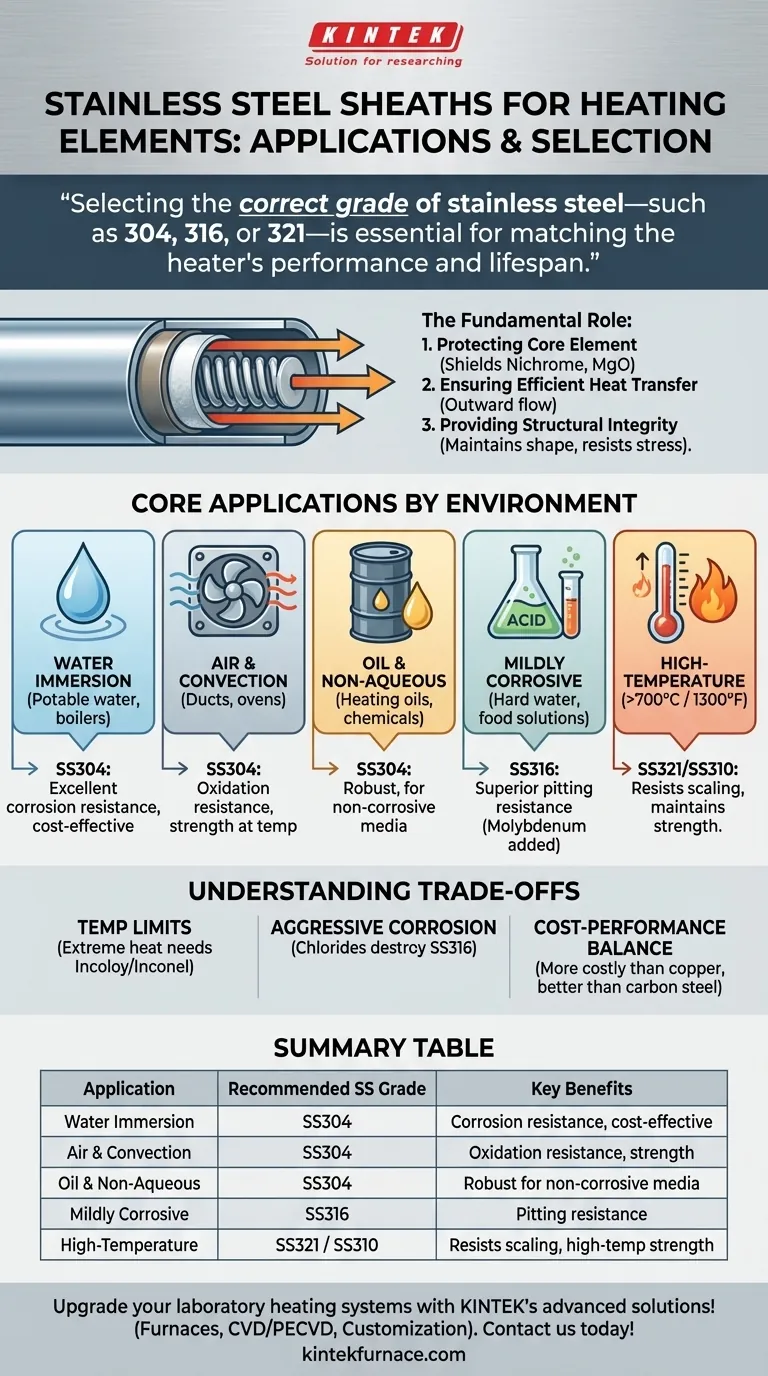

The critical takeaway is not simply that stainless steel is used, but that selecting the correct grade of stainless steel—such as 304, 316, or 321—is essential for matching the heater's performance and lifespan to its specific operating environment.

The Fundamental Role of the Sheath

A heating element's sheath is far more than a simple cover. It is a critical component that performs several functions simultaneously.

Protecting the Core Element

The primary job of the sheath is to physically isolate and protect the internal components. It shields the delicate resistance wire (typically Nichrome) and the compacted magnesium oxide (MgO) insulating powder from moisture, contaminants, and physical damage.

Ensuring Efficient Heat Transfer

The sheath material must be a good thermal conductor. Its purpose is to efficiently transfer the heat generated by the resistance wire outward into the medium being heated, whether it's water, air, oil, or a solid platen.

Providing Structural Integrity

Heating elements are often bent into complex shapes to fit specific applications. The sheath provides the necessary mechanical strength and rigidity to maintain this shape and resist vibration and stress during operation.

Core Applications by Environment

The choice of a specific stainless steel grade is dictated by the environment in which the heater will operate.

Water Immersion Heating

For heating potable water in boilers, residential water heaters, and industrial rinse tanks, SS304 is the industry standard. It provides excellent corrosion resistance against standard water supplies at a very effective price point.

Air and Convection Heating

In applications like duct heaters, ovens, and drying systems, the primary concerns are oxidation resistance and strength at temperature. SS304 is again a common and effective choice for most air heating applications up to its temperature limit.

Oil and Non-Aqueous Liquids

Heating oils, waxes, and various non-corrosive chemical solutions is a standard industrial task. The robust nature of SS304 makes it a suitable sheath material for these applications, as the risk of aqueous corrosion is absent.

Mildly Corrosive Environments

When dealing with hard water, deionized water, or certain food-grade solutions, the risk of chloride-induced pitting corrosion increases. In these cases, SS316 is the superior choice. Its addition of molybdenum significantly enhances its resistance to this specific type of corrosion.

High-Temperature Applications

For processes requiring sheath temperatures above approximately 700°C (1300°F), standard stainless grades begin to fail. High-temperature grades like SS321 (stabilized with titanium) or SS310 (high in chromium and nickel) are required to resist high-temperature scaling and maintain their strength.

Understanding the Trade-offs

While highly versatile, stainless steel is not the universal solution for every heating application. Understanding its limitations is key to avoiding premature failure.

Temperature Limitations

Standard stainless steel grades lose significant strength and rapidly oxidize at very high temperatures. For extreme environments, such as those found in furnaces or specialized industrial processes, more exotic and expensive alloys like Incoloy or Inconel are necessary.

Vulnerability to Aggressive Corrosion

The term "stainless" can be misleading; it is stain-less, not stain-proof. High concentrations of chlorides, hydrofluoric acid, or other aggressive chemicals will rapidly attack and destroy even SS316 sheaths. These environments demand specialized materials.

The Cost-Performance Balance

While cost-effective, stainless steel is more expensive than basic carbon steel or copper. For low-temperature, dry, and non-corrosive applications, a simpler steel or copper sheath may be a more economical choice, though it comes at the expense of corrosion resistance and temperature range.

Making the Right Choice for Your Application

Use these guidelines to select the appropriate sheath material based on your primary design goal.

- If your primary focus is general-purpose heating in non-corrosive media (clean water, air, oil): Start with SS304 as your default choice for its excellent balance of performance and cost.

- If your primary focus is resistance to mild corrosion (e.g., process water, food applications): Specify SS316 for its superior protection against chloride-induced pitting.

- If your primary focus is high-temperature performance (above 700°C / 1300°F): Select a specialized grade like SS321 or SS310 to prevent oxidation and maintain structural integrity.

- If your primary focus is extreme environments with aggressive chemicals or ultra-high heat: You must look beyond stainless steel to high-nickel alloys like Incoloy or Inconel.

Matching the sheath material to the application is the foundation of a reliable and long-lasting heating system.

Summary Table:

| Application | Recommended Stainless Steel Grade | Key Benefits |

|---|---|---|

| Water Immersion Heating | SS304 | Excellent corrosion resistance, cost-effective |

| Air and Convection Heating | SS304 | Oxidation resistance, strength at temperature |

| Oil and Non-Aqueous Liquids | SS304 | Robust performance, suitable for non-corrosive media |

| Mildly Corrosive Environments | SS316 | Enhanced resistance to chloride-induced pitting |

| High-Temperature Applications | SS321 or SS310 | Resists scaling, maintains strength above 700°C |

Upgrade your laboratory heating systems with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our tailored heating solutions can benefit your specific applications and drive your research forward!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance