At its core, Chemical Vapor Deposition (CVD) is a family of processes used to create high-performance thin films and coatings. The many types of CVD are distinguished primarily by the energy source used to drive the chemical reaction (heat, plasma), the operating pressure (atmospheric or low), and the specific chemical precursors used. The most common industrial variants include Low-Pressure CVD (LPCVD), Plasma-Enhanced CVD (PECVD), and Metal-Organic CVD (MOCVD).

The fundamental challenge in any deposition process is controlling a chemical reaction on a substrate's surface. The various types of CVD are not competing technologies, but rather a toolkit of specialized solutions, each optimized to navigate the trade-offs between deposition temperature, film quality, cost, and material compatibility.

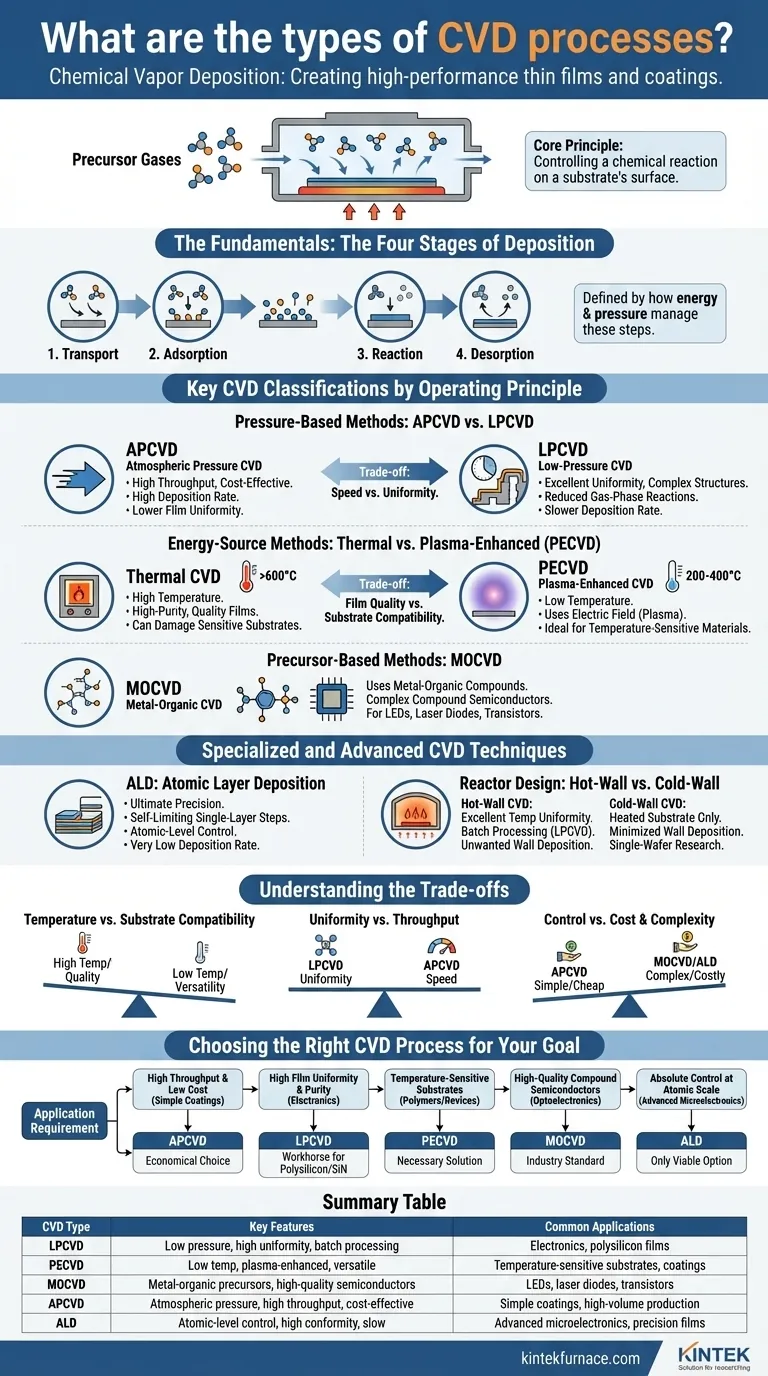

The Fundamentals: What Defines a CVD Process?

All CVD processes share a common sequence of events to build a film layer-by-layer. Understanding this foundation is key to differentiating between the various techniques.

The Four Stages of Deposition

- Transport: Precursor gases are introduced into a reaction chamber and diffuse toward the substrate.

- Adsorption: The precursor gas molecules stick to the surface of the substrate.

- Reaction: On the heated surface, the adsorbed molecules undergo a chemical reaction, forming the desired solid film and gaseous by-products.

- Desorption: The gaseous by-products detach from the surface and are exhausted from the chamber.

The "type" of CVD is defined by how it manages and energizes this four-step process.

Key CVD Classifications by Operating Principle

The primary methods for classifying CVD processes revolve around pressure, the energy source used, and the type of chemical precursors.

Pressure-Based Methods: APCVD vs. LPCVD

Pressure directly influences the speed and quality of the deposition.

- Atmospheric Pressure CVD (APCVD): This process operates at normal atmospheric pressure. It allows for very high deposition rates and high throughput, making it cost-effective. However, gas flow dynamics at this pressure can lead to lower film uniformity.

- Low-Pressure CVD (LPCVD): By operating in a partial vacuum, LPCVD significantly reduces gas-phase reactions. This allows precursor molecules to cover the substrate more evenly, resulting in excellent film uniformity and the ability to coat complex, three-dimensional structures. The trade-off is a generally slower deposition rate.

Energy-Source Methods: Thermal vs. Plasma-Enhanced (PECVD)

The energy provided to the system determines the temperature needed for the reaction.

- Thermal CVD: This is the most traditional form, where the substrate is heated to high temperatures (often >600°C) to provide the thermal energy needed to break chemical bonds. It produces very high-purity, high-quality films. Its major limitation is that the high temperatures can damage many substrates, such as plastics or certain electronic components.

- Plasma-Enhanced CVD (PECVD): This technique uses an electric field to generate a plasma (an ionized gas). The high-energy electrons in the plasma break down precursor gases at much lower temperatures (typically 200-400°C). This makes PECVD essential for depositing films on temperature-sensitive materials.

Precursor-Based Methods: MOCVD

Sometimes, the process is defined by the unique chemistry involved.

- Metal-Organic CVD (MOCVD): This highly versatile process uses metal-organic compounds as precursors. MOCVD is the cornerstone for manufacturing complex compound semiconductors, which are critical for high-performance applications like LEDs, laser diodes, and high-frequency transistors.

Specialized and Advanced CVD Techniques

Beyond the primary classifications, several other important variants exist for specific goals.

Atomic Layer Deposition (ALD): Ultimate Precision

ALD can be considered an advanced subclass of CVD. It separates the chemical reaction into a sequence of self-limiting, single-layer steps. This provides unparalleled, atomic-level control over film thickness and conformity, but at the cost of a very low deposition rate.

Reactor Design: Hot-Wall vs. Cold-Wall

The reactor's thermal design also defines the process.

- Hot-Wall CVD: The entire chamber, including the walls and the substrate, is heated. This promotes excellent temperature uniformity across many substrates at once, making it ideal for batch processing with LPCVD. The downside is unwanted film deposition on the chamber walls, requiring frequent cleaning.

- Cold-Wall CVD: Only the substrate (and its holder) is directly heated, while the chamber walls remain cool. This minimizes unwanted wall deposition and is common in single-wafer research and MOCVD systems.

Niche Applications: Hot Filament CVD (HFCVD)

This method uses a heated wire (filament) to thermally decompose precursor gases. Its primary application is the synthesis of high-quality polycrystalline diamond films.

Understanding the Trade-offs

Choosing a CVD process is an engineering decision based on balancing competing priorities. There is no single "best" method.

Temperature vs. Substrate Compatibility

High-temperature processes like Thermal CVD produce excellent crystalline quality but are incompatible with many materials. Low-temperature PECVD offers versatility for sensitive substrates but may result in films with different properties (e.g., higher hydrogen content).

Uniformity vs. Throughput

LPCVD delivers superior uniformity and the ability to coat many substrates in a batch, but the process is relatively slow. APCVD is much faster and simpler but struggles to achieve the same level of film consistency.

Control vs. Cost & Complexity

Simple APCVD systems are relatively inexpensive. In contrast, MOCVD and ALD systems are highly complex and expensive but provide a level of chemical and thickness control that is unattainable with other methods.

Choosing the Right CVD Process for Your Goal

Your application's primary requirement should guide your selection.

- If your primary focus is high throughput and low cost for simple coatings: APCVD is often the most economical choice.

- If your primary focus is high film uniformity and purity for electronics: LPCVD is the classic workhorse for materials like polysilicon and silicon nitride.

- If you are depositing on temperature-sensitive substrates like polymers or pre-built devices: PECVD is the necessary solution.

- If you need to grow high-quality compound semiconductors for optoelectronics: MOCVD is the industry-standard technology.

- If your goal is absolute control over film thickness at the atomic scale for advanced microelectronics: ALD is the only viable option, despite its slow speed.

By understanding these core principles and trade-offs, you can confidently select the deposition technique that aligns perfectly with your technical and economic goals.

Summary Table:

| CVD Type | Key Features | Common Applications |

|---|---|---|

| LPCVD | Low pressure, high uniformity, batch processing | Electronics, polysilicon films |

| PECVD | Low temperature, plasma-enhanced, versatile | Temperature-sensitive substrates, coatings |

| MOCVD | Metal-organic precursors, high-quality semiconductors | LEDs, laser diodes, transistors |

| APCVD | Atmospheric pressure, high throughput, cost-effective | Simple coatings, high-volume production |

| ALD | Atomic-level control, high conformity, slow deposition | Advanced microelectronics, precision films |

Need a Custom CVD Solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your thin film deposition processes!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis