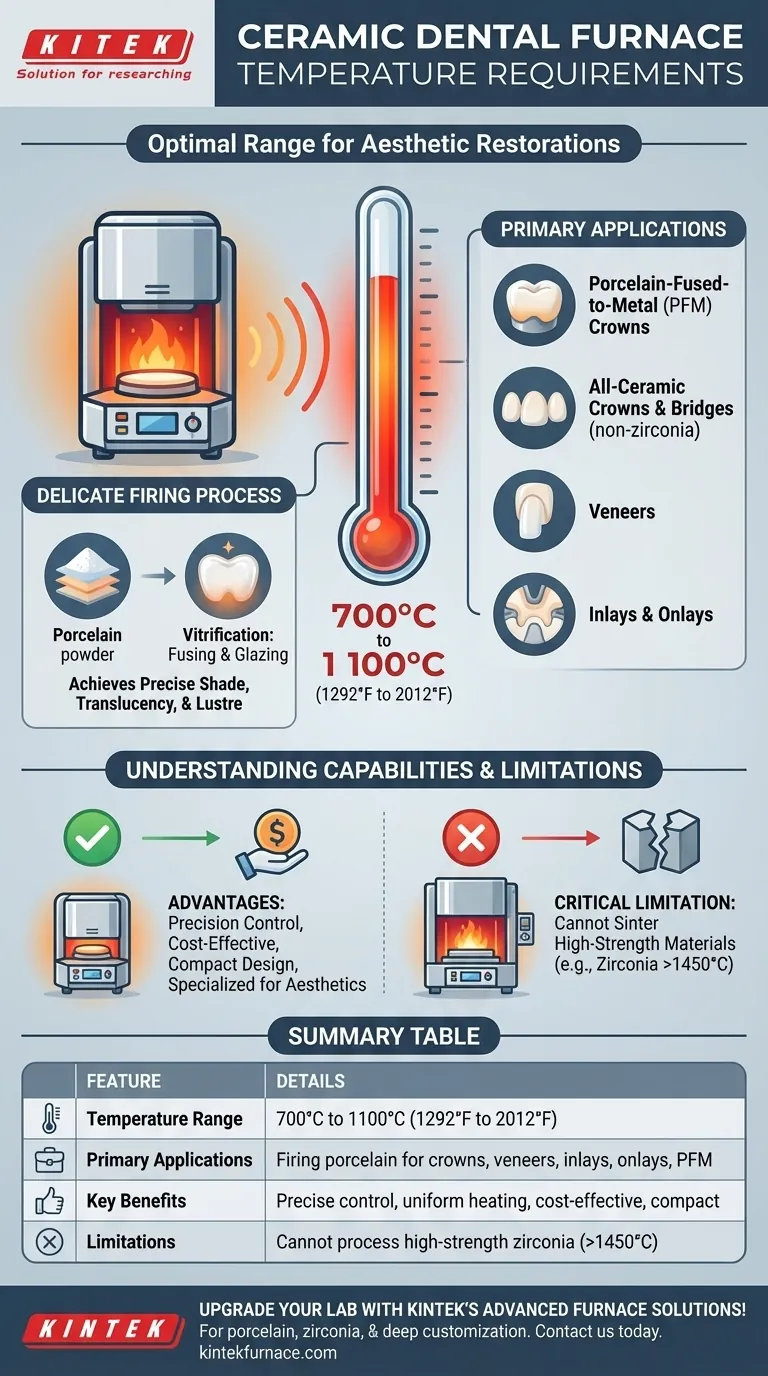

For dental professionals and laboratory technicians, the required temperature range for a ceramic dental furnace is typically between 700°C and 1100°C (1292°F to 2012°F). This specific operational window is not arbitrary; it is precisely tailored for the delicate process of firing dental porcelain and other low-fusing ceramics. This ensures the final restorations achieve their intended aesthetic properties, strength, and accurate fit.

A ceramic furnace's temperature range is a defining feature, not a limitation. It enables the meticulous control needed for beautiful porcelain restorations but intentionally excludes it from processing high-strength materials like zirconia, which require much higher sintering temperatures.

The Role of Temperature in Aesthetic Restorations

The primary function of a ceramic dental furnace is to transform layers of porcelain powder into a solid, durable, and lifelike restoration. The temperature protocol is the most critical variable in this process.

Achieving Precise Glaze and Shade

The 700°C to 1100°C range allows for highly controlled heating cycles. This precision is essential for developing the final shade, translucency, and surface lustre (glaze) of restorations like crowns, veneers, and inlays.

Slight deviations outside the ideal firing curve can result in a restoration that is too opaque, improperly shaded, or has a porous, weak structure.

The Firing Process Explained

Firing involves heating the ceramic particles until they fuse together—a process called vitrification. This happens well below the material's melting point.

The furnace's ability to hold specific temperatures and ramp up or down at a controlled rate is what ensures a complete and uniform fusion without warping or damaging the restoration.

Applications Driven by Temperature

This moderate temperature range is perfectly suited for a wide array of common dental restorations.

It is the standard for fabricating porcelain-fused-to-metal (PFM) crowns, all-ceramic crowns and bridges (excluding zirconia), veneers, inlays, and onlays.

Understanding the Trade-offs

Choosing a furnace requires understanding what its temperature capabilities both permit and prevent. The distinction between a ceramic furnace and a sintering furnace is fundamental.

The Critical Limitation: High-Strength Materials

The most significant limitation of a ceramic furnace is its inability to process materials that require high-temperature sintering.

High-strength ceramics like monolithic zirconia require temperatures well above 1450°C (2642°F) to achieve their final density and strength. A ceramic furnace simply cannot reach these temperatures.

Advantage: Specialization and Cost-Effectiveness

For a practice or lab that focuses on aesthetic porcelain work, this specialization is an advantage. Ceramic furnaces are typically more compact, energy-efficient, and cost-effective than their high-temperature counterparts.

Their design is optimized for one job, and they perform it with exceptional precision.

Advantage: User-Friendly and Compact Design

Because they do not need the heavy-duty insulation and power systems of sintering furnaces, ceramic furnaces are often smaller and more user-friendly.

This makes them a practical choice for in-office labs or smaller operations where space and ease of use are primary concerns.

Making the Right Choice for Your Lab

Selecting the correct furnace technology comes down to a clear assessment of the materials you intend to work with.

- If your primary focus is aesthetic porcelain work (PFM, veneers, feldspathic crowns): A standard ceramic furnace (700°C-1100°C) is the correct and most efficient tool for your needs.

- If your practice will fabricate restorations from monolithic zirconia: You must invest in a separate high-temperature sintering furnace capable of reaching 1450°C or higher.

- If you are building a full-service laboratory: You will almost certainly require both a ceramic furnace for porcelain application and a sintering furnace to handle the full spectrum of modern dental materials.

Understanding this fundamental temperature difference is the key to equipping your practice for predictable, high-quality results.

Summary Table:

| Feature | Details |

|---|---|

| Temperature Range | 700°C to 1100°C (1292°F to 2012°F) |

| Primary Applications | Firing porcelain for crowns, veneers, inlays, onlays, and PFM restorations |

| Key Benefits | Precise temperature control, uniform heating, cost-effectiveness, compact design |

| Limitations | Cannot process high-strength materials like zirconia (requires >1450°C) |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, whether you're working with porcelain or other materials. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision