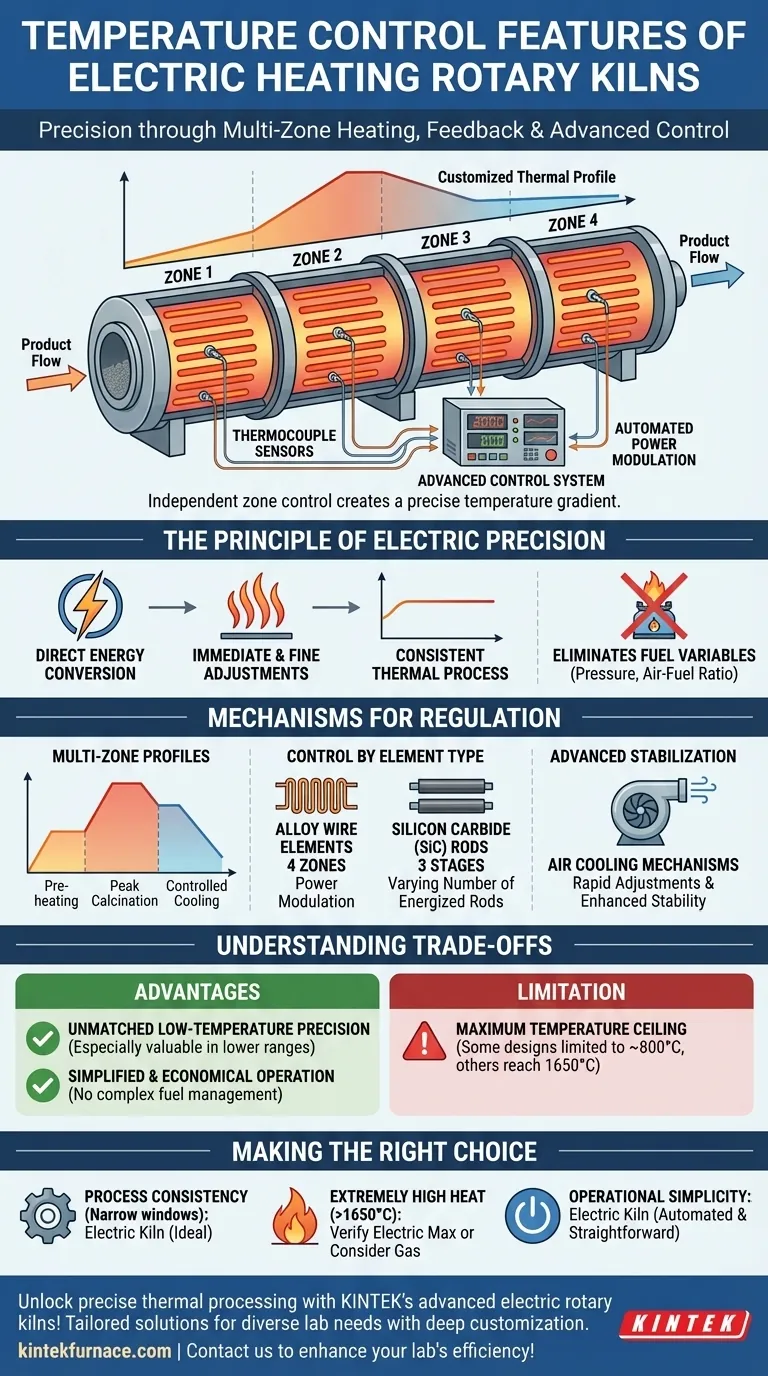

At their core, electric heating rotary kilns control temperature through a combination of multi-zone heating elements, precise feedback from thermocouples, and advanced control systems. Depending on the design, these kilns feature distinct temperature zones—often three or four—that can be regulated independently to create a highly customized thermal profile along the length of the kiln.

The defining feature of an electric rotary kiln is its ability to deliver exceptionally precise and stable temperature control. This is achieved by dividing the kiln into multiple, independently managed heating zones, allowing for customized heat patterns that are difficult to achieve with fuel-fired alternatives.

The Principle of Electric Precision

How Electric Heat Enables Control

Electric heating provides an inherent advantage in temperature regulation. Unlike gas or oil-fired systems that rely on combustion, electric elements convert electrical energy directly into heat, allowing for immediate and finely-tuned power adjustments.

This direct control eliminates variables like fuel pressure, air-fuel ratios, and atmospheric conditions, resulting in a more stable and repeatable thermal process.

The Role of Thermocouples

Thermocouples are the essential sensors in this system. These devices are placed within the kiln, often with one per heating zone, to provide continuous, real-time temperature data.

This feedback loop allows the control system to make constant, minute adjustments to the power supplied to each heating element, ensuring the process temperature remains exactly at the desired setpoint.

Mechanisms for Temperature Regulation

Multi-Zone Heating Profiles

The most powerful feature is the use of multiple, separately controllable temperature zones. This allows operators to create a specific temperature gradient that a product experiences as it travels through the kiln.

For example, a process might require a gradual pre-heating stage, a peak calcination temperature, and a controlled cooling phase. An electric kiln with three or four zones can map this profile precisely.

Control by Heating Element Type

The specific control mechanism can vary based on the type of heating element used.

-

Alloy Wire Elements: Kilns using alloy heating wires are often configured with four separate temperature zones. Each zone's temperature is typically managed by a controller that modulates the power sent to the elements.

-

Silicon Carbide (SiC) Rods: Designs with silicon carbide elements may feature three-stage temperature control. In some models, temperature is adjusted by varying the number of energized rods, offering a different method of power modulation.

Advanced Stabilization Features

Beyond just heating, superior control also involves managing heat. Some advanced electric kilns incorporate air cooling mechanisms to help stabilize temperatures and ensure rapid, precise adjustments when needed.

Understanding the Trade-offs

Advantage: Unmatched Low-Temperature Precision

Electric kilns excel at providing precise control across the entire temperature spectrum. This is particularly valuable in lower temperature ranges, where gas-fired kilns often struggle to maintain stability and accuracy.

Advantage: Simplified and Economical Operation

Operating an electric kiln is often simpler than a fuel-fired one. There is no complex fuel management, storage, or delivery system to maintain. This simplification can lead to more economical operation for processes with narrow temperature requirements.

Limitation: Maximum Temperature Ceiling

While versatile, some electric rotary kilns may have a lower maximum operating temperature compared to their gas-fired counterparts. While general ranges can reach up to 1650°C (3000°F), certain designs, particularly for indirect heating, may be limited to around 800°C. This makes it a critical factor for applications requiring extremely high temperatures.

Making the Right Choice for Your Process

Choosing the right kiln technology depends entirely on your specific process requirements.

- If your primary focus is process consistency and narrow temperature windows: An electric kiln is the ideal choice due to its precise, multi-zone control capabilities.

- If your primary focus is applications requiring extremely high heat (above 1650°C): You must carefully verify the specific electric kiln's maximum temperature, as a specialized gas-fired kiln may be required.

- If your primary focus is operational simplicity and repeatability: The straightforward, automated control of an electric kiln eliminates the complexities of fuel management.

Ultimately, the superior temperature control of an electric rotary kiln empowers you to achieve consistent, high-quality results for a wide range of thermal processes.

Summary Table:

| Feature | Description |

|---|---|

| Multi-Zone Heating | Independent temperature control in 3-4 zones for customized thermal profiles |

| Thermocouple Feedback | Real-time temperature monitoring for precise adjustments |

| Advanced Control Systems | Automated power modulation for stable setpoint maintenance |

| Heating Element Types | Alloy wires (4 zones) or SiC rods (3 stages) for varied control |

| Air Cooling Mechanisms | Enhanced stabilization and rapid temperature adjustments |

| Temperature Range | Up to 1650°C, with precise low-temperature control |

| Operational Simplicity | No fuel management, economical for narrow temperature needs |

Unlock precise thermal processing with KINTEK's advanced electric rotary kilns! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace solutions, including Rotary Furnaces, to meet your unique experimental needs. Our deep customization capability ensures optimal performance for consistent, high-quality results. Contact us today to discuss how we can enhance your lab's efficiency and achieve your thermal processing goals!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules