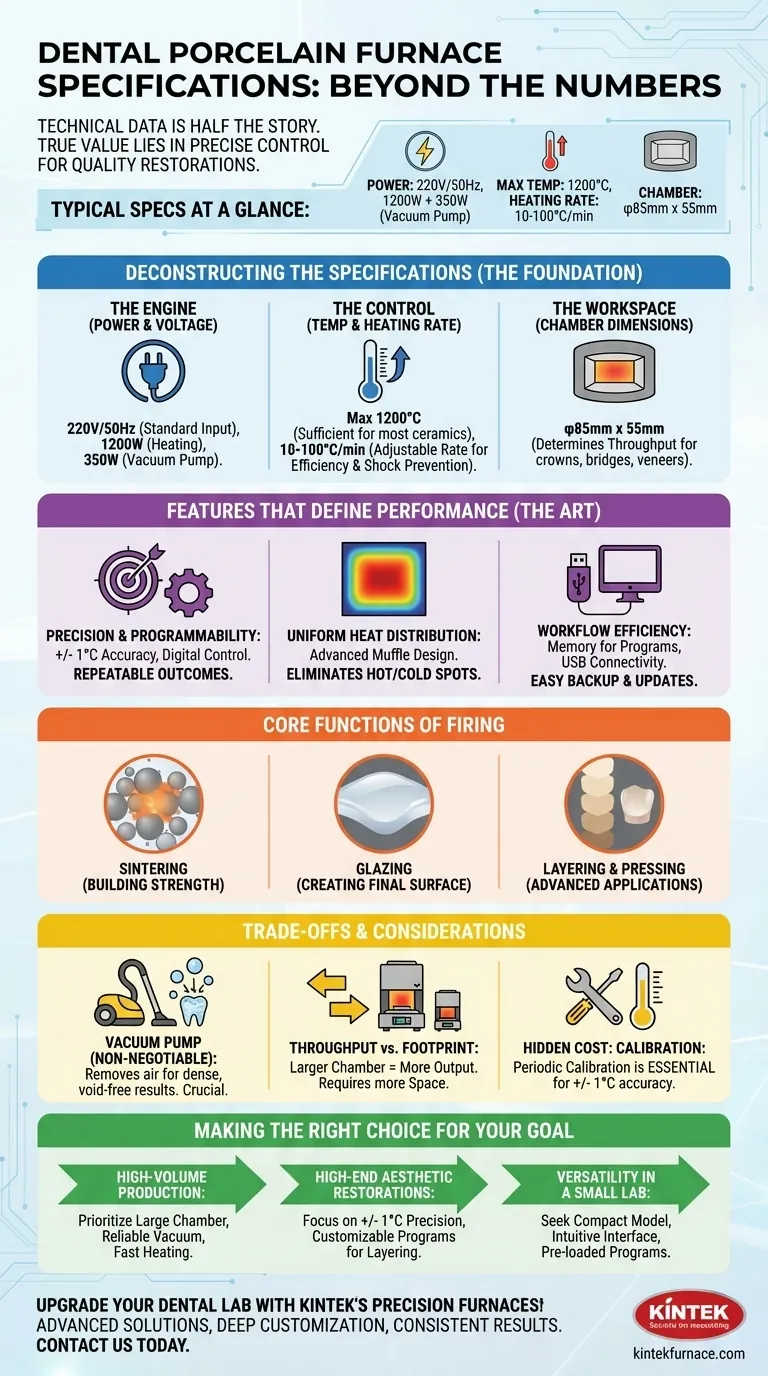

At a glance, a typical dental porcelain furnace operates on a 220V/50Hz power supply, consumes around 1200W (plus an additional 350W for the vacuum pump), and can reach a maximum temperature of 1200°C. Its heating rate is adjustable from 10 to 100°C per minute, and its internal firing chamber is generally around 85mm in diameter and 55mm in height.

The technical specifications on paper are only half the story. The true value of a dental furnace lies in its ability to translate those numbers into precise, repeatable control over the firing cycle, which is the determining factor in the strength, fit, and aesthetics of a final dental restoration.

Deconstructing the Specifications: What Each Number Means

Understanding the core specifications provides a baseline for what a furnace can do. It's the foundation upon which performance is built.

The Engine: Power and Voltage

The standard 220V/50Hz input voltage is a common electrical requirement for this type of equipment in many regions.

The power rating, typically 1200W + 350W, reveals two key components. The 1200W refers to the heating element's power, dictating how quickly the furnace can reach its target temperature. The additional 350W is almost always for the external vacuum pump, a critical component for creating dense, void-free restorations.

The Control: Temperature and Heating Rate

A maximum temperature of 1200°C is more than sufficient to process the vast majority of dental ceramics, including feldspathic porcelains, leucite-reinforced materials, and lithium disilicate.

The true art is in the heating rate. A programmable range of 10°C to 100°C per minute gives the technician precise control. Slow rates are essential for preventing thermal shock in thick restorations, while faster rates can improve lab efficiency for smaller jobs.

The Workspace: Chamber Dimensions

The internal chamber size, often around φ85mm x 55mm, directly determines the furnace's throughput. This size dictates how many crowns, bridges, or veneers can be fired in a single cycle, impacting the overall productivity of a dental lab.

Beyond the Numbers: The Features That Define Performance

While base specifications are important, modern furnaces are defined by features that ensure consistency and ease of use. These capabilities are what truly separate a basic heater from a high-precision dental instrument.

Precision and Programmability

The single most critical feature is the ability to maintain temperature with extreme accuracy, often within +/- 1°C. This precision, combined with digital programmability via a touch-screen, ensures that every firing cycle is perfectly repeatable. This eliminates guesswork and is essential for achieving consistent clinical outcomes.

Uniform Heat Distribution

An advanced muffle or chamber design is engineered to provide uniform heat distribution. This prevents hot or cold spots within the chamber, ensuring that all restorations—regardless of their position on the firing tray—are sintered evenly. Uneven heating is a primary cause of cracks and fitting errors.

Workflow Efficiency

Modern furnaces almost always include memory for storing dozens or even hundreds of custom firing programs. USB connectivity is also a key feature, allowing technicians to easily back up programs, transfer them between furnaces, or install software updates from the manufacturer.

Understanding the Core Functions of Firing

A furnace uses its precise control over heat and vacuum to perform several distinct functions, each vital to creating a final restoration.

Sintering: Building Strength

Sintering is the process of heating porcelain powder to a point where the particles fuse together, drastically increasing the material's density and strength without fully melting it. The furnace's ability to hold a precise temperature for a specific "soak time" is critical to this process.

Glazing: Creating the Final Surface

After a restoration is shaped and sintered, a final, lower-temperature glaze firing is performed. This melts a thin surface layer, creating a smooth, non-porous, and stain-resistant surface that mimics the appearance of natural tooth enamel.

Layering and Pressing: Advanced Applications

For high-end aesthetic work, furnaces enable multi-stage layering, where different shades of porcelain are applied and fired in separate cycles. Many furnaces are also capable of pressing ceramics, a process used for materials like lithium disilicate to create monolithic crowns and bridges with exceptional strength.

Understanding the Trade-offs and Considerations

Choosing or operating a furnace involves balancing several practical factors.

The Vacuum Pump is Non-Negotiable

Firing under vacuum is essential for removing air trapped between porcelain particles. Without a powerful and reliable vacuum, the final restoration will be porous, weak, and aesthetically compromised by bubbles. The performance of the pump is just as important as the furnace itself.

Throughput vs. Footprint

A furnace with a larger chamber can process more work simultaneously, which is ideal for a high-volume lab. However, this comes with a larger physical footprint. Smaller labs may find a more compact unit to be a more efficient use of limited space.

The Hidden Cost: Calibration

To maintain their stated +/- 1°C accuracy, porcelain furnaces require periodic calibration. This process ensures the temperature displayed on the screen matches the true temperature inside the chamber. Neglecting calibration will inevitably lead to inconsistent results and failed restorations.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its capabilities to the specific needs of your dental lab.

- If your primary focus is high-volume production: Prioritize a furnace with a larger chamber, a reliable vacuum system, and efficient, fast-heating programs to maximize daily throughput.

- If your primary focus is high-end aesthetic restorations: Focus on a furnace renowned for its temperature precision (+/- 1°C) and highly customizable programs that allow for complex, multi-stage layering.

- If your primary focus is versatility in a smaller lab: Seek a compact model with an intuitive interface and pre-loaded programs for a wide range of common dental ceramic materials.

Ultimately, the best furnace is a tool that reliably and repeatedly delivers the precise thermal environment your chosen materials require to become successful restorations.

Summary Table:

| Specification | Typical Value | Key Insight |

|---|---|---|

| Power Supply | 220V/50Hz | Common standard for stable operation in many regions |

| Power Consumption | 1200W (heating) + 350W (vacuum pump) | Heating power affects speed; vacuum pump is essential for dense restorations |

| Max Temperature | 1200°C | Sufficient for most dental ceramics, including lithium disilicate |

| Heating Rate | 10-100°C per minute | Programmable range prevents thermal shock and boosts efficiency |

| Chamber Dimensions | φ85mm x 55mm | Dictates throughput for crowns, bridges, and veneers |

| Temperature Accuracy | +/- 1°C | Critical for repeatable, precise firing cycles |

| Key Features | Uniform heat distribution, USB connectivity, program memory | Ensures even sintering, easy updates, and workflow efficiency |

Upgrade your dental lab with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, whether for high-volume production, aesthetic restorations, or versatile small-lab setups. Achieve consistent, reliable results—contact us today to discuss how our furnaces can enhance your workflow and deliver superior dental restorations!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What type of service and maintenance does a sintering furnace for dental zirconia require? Essential Guide for Lab Quality

- What are the main types of dental porcelain furnaces and their characteristics? Choose the Right Furnace for Your Dental Lab

- What language options are available on the dental zirconia sintering furnace? Ensure Precision and Efficiency in Your Lab

- What are the benefits of using dental ceramic furnaces? Achieve Superior Aesthetics and Efficiency

- How do the cycle times of ceramic dental furnaces compare to zirconia furnaces? Uncover Key Differences for Your Lab

- What is the purpose of a dental ceramic furnace? Achieve Strong, Lifelike Dental Restorations

- What are the main applications of zirconia sintering furnaces? Unlock High-Strength Ceramics for Dental and Industrial Use

- What are the main components of a porcelain furnace? Unlock Precision for Dental Restorations