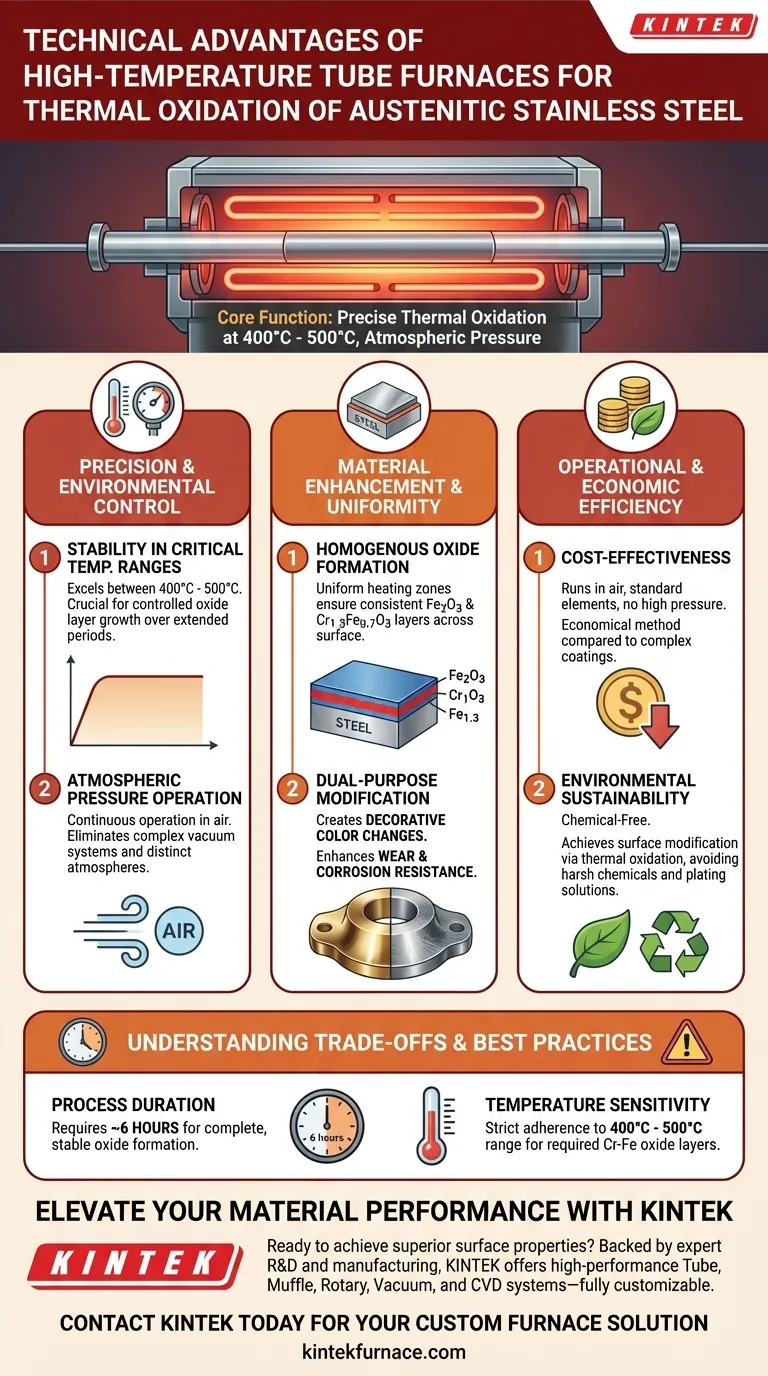

High-temperature tube furnaces offer superior process control for the thermal oxidation of austenitic stainless steel, particularly within the critical 400°C to 500°C window. By maintaining a stable atmospheric pressure environment, these systems allow for precise, long-duration heating cycles that are essential for developing consistent surface properties without complex vacuum equipment.

The core advantage lies in the furnace's ability to maintain uniform heating zones, creating a homogenous oxide layer that enhances both the material's wear resistance and its decorative appearance in a cost-effective, environmentally friendly manner.

Precision and Environmental Control

Stability in Critical Temperature Ranges

These furnaces excel at maintaining stable temperatures specifically between 400°C and 500°C. This precise thermal window is crucial for the controlled growth of oxide layers, ensuring the process remains stable over extended periods.

Atmospheric Pressure Operation

The system allows for continuous operation in air at atmospheric pressure. This eliminates the need for complex vacuum systems or chemically distinct atmospheres, streamlining the oxidation process.

Material Enhancement and Uniformity

Homogenous Oxide Formation

Uniform heating zones are a hallmark of tube furnaces. This consistency ensures the formation of homogenous iron oxide (Fe2O3) and chromium-iron oxide (Cr1.3Fe0.7O3) layers across the entire sample surface, avoiding irregular patches or weak spots.

Dual-Purpose Surface Modification

The process yields two distinct technical benefits simultaneously. It creates decorative color changes while significantly improving functional properties, specifically enhancing the steel's wear and corrosion resistance.

Operational and Economic Efficiency

Cost-Effectiveness

Because the process runs in air and utilizes standard thermal elements without high-pressure requirements, it offers a cost-effective method for surface treatment compared to more complex coating technologies.

Environmental Sustainability

The method is inherently environmentally friendly. It achieves surface modification through thermal oxidation rather than utilizing harsh chemical baths or galvanic plating solutions often associated with metal finishing.

Understanding the Trade-offs

Process Duration Requirements

High-quality oxidation is not instantaneous in this configuration. The process requires extended dwell times, typically around 6 hours, to ensure the complete formation and stability of the oxide structures.

Temperature Sensitivity

The benefits described are strictly tied to the 400°C to 500°C range. Deviating from this window may compromise the formation of the specific Cr-Fe oxide layers required for enhanced protection.

Making the Right Choice for Your Goal

To maximize the utility of a high-temperature tube furnace for your specific application:

- If your primary focus is decorative finishes: Leverage the uniform heating zones to ensure consistent, repeatable coloration across the entire surface area of the steel.

- If your primary focus is functional durability: Adhere strictly to the full 6-hour cycle time to maximize the homogeneity of the protective Cr1.3Fe0.7O3 layers for optimal corrosion resistance.

Ultimately, this thermal processing method transforms standard austenitic stainless steel into a higher-performance material through a clean, controlled, and economical mechanism.

Summary Table:

| Feature | Technical Advantage | Benefit for Stainless Steel |

|---|---|---|

| Temperature Range | 400°C - 500°C Stability | Ensures consistent growth of protective oxide layers |

| Atmosphere | Atmospheric Pressure Air | Cost-effective operation without complex vacuum systems |

| Heating Zone | Uniform Thermal Distribution | Homogenous formation of Fe2O3 and Cr1.3Fe0.7O3 |

| Processing Time | 6-Hour Dwell Cycles | Maximizes wear resistance and decorative consistency |

| Sustainability | Chemical-Free Oxidation | Environmentally friendly alternative to plating/baths |

Elevate Your Material Performance with KINTEK

Ready to achieve superior surface properties with precision thermal processing? Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory or production needs.

Whether you are refining austenitic stainless steel or developing advanced materials, our high-temperature furnaces provide the stability and control required for excellence. Contact KINTEK today to find your custom furnace solution and see how our expertise can drive your innovation forward.

Visual Guide

References

- T. Borowski, Bogusława Adamczyk‐Cieślak. Wear and Corrosion Resistance of Thermally Formed Decorative Oxide Layers on Austenitic Steel. DOI: 10.3390/met15070707

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Can a quartz tube furnace be used for controlled atmosphere experiments? Achieve Precise Heat and Gas Control

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What optional features are available for tube furnaces? Enhance Your Materials Processing with Precision Control

- How does a high-precision tube sintering furnace contribute to the crystal structure formation of Li3-3xScxSb?

- How does a horizontal tube furnace work? Master Precise Thermal Processing for Your Lab

- What role does a tube furnace play in NaRu2O4 synthesis? Master Solid-State Reaction & Phase Purity

- Why is a tube furnace preferred for NRBBO:Eu2+ synthesis? Achieve Precise Atmosphere Control for Phosphors

- What industries commonly use tube furnaces? Essential for High-Tech Materials and Electronics