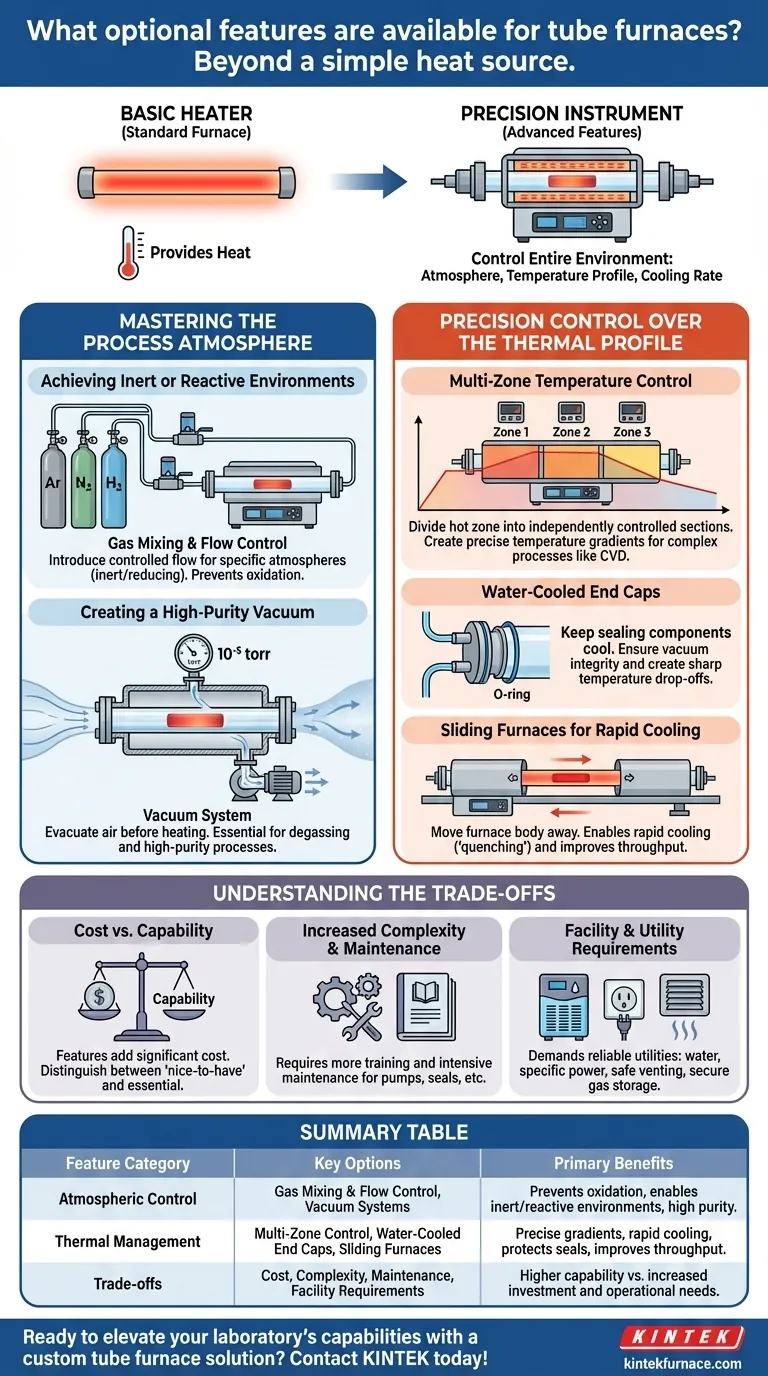

Beyond a simple heat source, a modern tube furnace can be configured with a range of optional features that transform it into a precision instrument. The most significant options enable complete control over the processing atmosphere through vacuum systems and gas mixing capabilities, as well as advanced thermal management using water-cooled end caps and multi-zone controllers.

A standard tube furnace provides heat. Optional features allow you to precisely control the entire environment inside the tube—its atmosphere, temperature profile, and cooling rate—turning a basic heater into a sophisticated materials processing tool.

Beyond Heating: Mastering the Process Atmosphere

The most transformative optional features are those that allow you to move beyond heating in ambient air. Controlling the gas environment is critical for preventing oxidation and enabling a wide range of chemical processes.

Achieving Inert or Reactive Environments

A gas mixing and flow control system is a common and powerful upgrade. This allows you to introduce a controlled flow of one or more gases into the processing tube.

This feature is essential for creating specific atmospheres, such as an inert environment using argon or nitrogen to protect sensitive materials from oxygen, or a reducing environment using hydrogen or forming gas.

Creating a High-Purity Vacuum

For the highest level of atmospheric purity, a vacuum system is indispensable. This involves adding sealed flanges, vacuum-tight fittings, and one or more pumps to evacuate the air from the process tube before heating or backfilling with a high-purity gas.

High-performance systems can achieve vacuum levels down to 10⁻⁵ torr, which is critical for applications like degassing materials or certain thin-film deposition processes that are intolerant of contaminants.

Precision Control Over the Thermal Profile

Controlling the temperature is a furnace's primary job, but optional features offer much more granular control over how and where that heat is applied and removed.

Multi-Zone Temperature Control

While a standard furnace has a single heated zone with one controller, an optional multi-zone configuration divides the hot zone into several independently controlled sections (often up to three).

This allows you to create precise temperature gradients along the length of the tube. This capability is crucial for advanced processes like chemical vapor deposition (CVD), where different temperature zones drive different stages of a reaction.

Water-Cooled End Caps

Water-cooled end caps or flanges serve a critical dual purpose in atmosphere-controlled furnaces.

First, they keep the sealing components, like rubber O-rings, cool and functional, ensuring the integrity of your vacuum or positive-pressure gas environment. Second, they create a very sharp temperature drop-off at the ends of the hot zone, which can be vital for process definition.

Sliding Furnaces for Rapid Cooling

Some designs feature a compact sliding mechanism that allows the furnace body to be moved away from the process tube. This exposes the tube to ambient air, enabling rapid cooling or "quenching" of the sample.

This feature dramatically improves sample throughput and provides a way to "freeze" a material's structure at a specific point in the thermal cycle.

Understanding the Trade-offs

Adding features provides capability, but it also introduces complexity and cost. A clear understanding of the trade-offs is essential for making a sound investment.

Cost vs. Capability

Every feature, from a simple gas port to a high-vacuum turbomolecular pumping station, adds significant cost. It is critical to distinguish between a "nice-to-have" feature and one that is essential for your core process.

Increased Complexity and Maintenance

A furnace with integrated gas mixing and vacuum systems is a far more complex instrument. It requires more user training to operate safely and correctly, as well as more intensive maintenance for pumps, seals, and gas lines.

Facility and Utility Requirements

Advanced features demand more from your facility. A water-cooling system requires a reliable water source or a dedicated chiller. Vacuum pumps may require specific power outlets and safe exhaust venting. Gas systems require secure cylinder storage and properly routed plumbing.

Making the Right Choice for Your Goal

Select features not based on what is available, but on what your specific application demands.

- If your primary focus is annealing in a controlled atmosphere: A gas flow system with well-sealed end caps is your most critical feature.

- If your primary focus is high-purity material synthesis (like CVD): You will need a combination of a gas mixing system, a vacuum system, and multi-zone temperature control.

- If your primary focus is high-throughput sample testing: A sliding furnace design for rapid cooling and software for automated data logging will provide the most value.

- If your primary focus is basic heat treatment in air: A standard furnace without atmospheric controls may be perfectly sufficient and far more cost-effective.

Ultimately, choosing the right options allows you to build a tool perfectly tailored to your scientific or production objectives.

Summary Table:

| Feature Category | Key Options | Primary Benefits |

|---|---|---|

| Atmospheric Control | Gas Mixing & Flow Control, Vacuum Systems | Prevents oxidation, enables inert/reactive environments, high purity for sensitive processes |

| Thermal Management | Multi-Zone Control, Water-Cooled End Caps, Sliding Furnaces | Precise temperature gradients, rapid cooling, protects seals, improves throughput |

| Trade-offs | Cost, Complexity, Maintenance, Facility Requirements | Higher capability vs. increased investment and operational needs |

Ready to elevate your laboratory's capabilities with a custom tube furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your experimental requirements. Whether you need precise atmospheric control, multi-zone heating, or rapid cooling features, we can help you achieve superior results. Contact us today to discuss how we can support your materials processing goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents