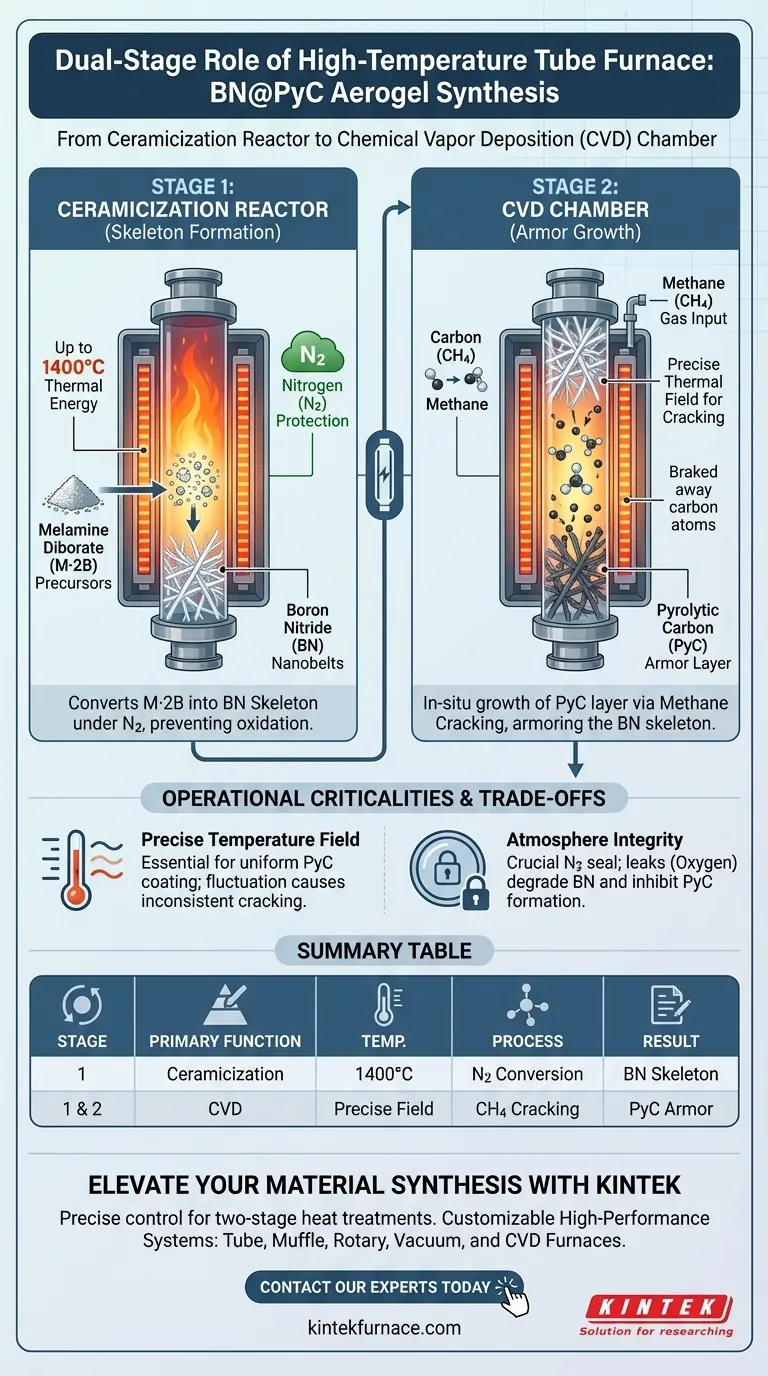

The high-temperature tube furnace serves two distinct, critical functions in the synthesis of BN@PyC aerogels: it acts first as a ceramicization reactor and second as a Chemical Vapor Deposition (CVD) chamber. In the initial stage, it supplies thermal energy up to 1400°C under nitrogen to convert melamine diborate precursors into boron nitride nanobelts. In the subsequent stage, it provides the precise thermal environment necessary to crack methane gas, facilitating the growth of a pyrolytic carbon armor layer directly onto the nanobelts.

The furnace enables a sequential transformation: first providing the high thermal energy required to ceramicize precursors into a BN skeleton, and second, creating a controlled chemical vapor deposition environment to armor that skeleton with carbon.

Stage 1: Ceramicization of the Skeleton

Establishing the Thermal Environment

The primary role of the furnace in the first stage is to generate and maintain intense heat, reaching temperatures up to 1400°C.

This high thermal energy is the driving force required to initiate the chemical transformation of the raw material. Specifically, it converts melamine diborate (M·2B) precursors into the desired ceramic structure.

Formation of Boron Nitride Nanobelts

Under these high-temperature conditions, the precursor undergoes ceramicization.

The furnace facilitates the reorganization of the molecular structure, turning the precursor into stable boron nitride (BN) nanobelts. This creates the fundamental "skeleton" or core framework of the aerogel.

Atmospheric Protection

Crucially, the furnace maintains a strictly controlled atmosphere throughout this process.

By operating under nitrogen protection, the furnace prevents oxidation and ensures the purity of the boron nitride phase. This protective environment is essential for achieving the correct chemical stoichiometry.

Stage 2: In-Situ Armor Growth

Functioning as a CVD Reactor

In the second stage, the role of the tube furnace shifts from simple heating to acting as a sophisticated Chemical Vapor Deposition (CVD) reaction chamber.

The equipment must transition from the synthesis parameters of the first stage to the deposition parameters of the second without compromising the sample's integrity.

Methane Cracking and Deposition

The furnace provides a precise temperature field specifically calibrated to crack methane gas introduced into the tube.

The energy supplied breaks down the methane molecules, releasing carbon atoms. These atoms then deposit onto the previously formed BN nanobelts.

Creating the Pyrolytic Carbon Layer

This process results in the in-situ growth of a pyrolytic carbon (PyC) layer.

This layer acts as an "armor" for the boron nitride nanobelts. The uniformity of this coating relies heavily on the furnace's ability to maintain stable temperatures and gas flow, ensuring the carbon is deposited evenly across the complex aerogel structure.

Operational Criticalities and Trade-offs

The Necessity of Precise Temperature Fields

While high heat is a requirement, the precision of the temperature field is the determining factor for quality.

If the temperature fluctuates or is uneven, the methane cracking in the second stage will be inconsistent. This can lead to non-uniform PyC coatings, leaving parts of the BN skeleton unprotected or creating overly thick carbon deposits that alter the material's mechanical properties.

Atmosphere Integrity

The reliance on nitrogen protection highlights a critical vulnerability: seal integrity.

Even minor leaks in the tube furnace can introduce oxygen. At temperatures approaching 1400°C, oxygen contamination would catastrophically degrade the boron nitride or inhibit the proper formation of the pyrolytic carbon layer. The "protective atmosphere" is only as good as the furnace's sealing mechanisms.

Making the Right Choice for Your Goal

To optimize the synthesis of BN@PyC aerogels, you must view the furnace not just as a heater, but as a dual-stage reactor.

- If your primary focus is Structural Integrity (The Core): Prioritize the furnace's ability to reach and stably hold 1400°C under nitrogen to ensure complete ceramicization of the M·2B precursor into robust BN nanobelts.

- If your primary focus is Surface Functionalization (The Armor): Focus on the precision of the temperature field during the CVD stage, as this dictates the uniformity and quality of the pyrolytic carbon coating derived from methane cracking.

Success depends on utilizing the furnace to precisely balance the high-energy demands of ceramicization with the delicate control required for vapor deposition.

Summary Table:

| Stage | Primary Function | Temperature | Key Process | Resulting Structure |

|---|---|---|---|---|

| Stage 1 | Ceramicization Reactor | Up to 1400°C | Precursor conversion under N2 | Boron Nitride (BN) Nanobelt Skeleton |

| Stage 2 | CVD Chamber | Precise Thermal Field | Methane (CH4) cracking | Pyrolytic Carbon (PyC) Armor Layer |

Elevate Your Material Synthesis with KINTEK

Precise temperature control and atmospheric integrity are the difference between a failed experiment and a breakthrough in BN@PyC aerogel development. At KINTEK, we understand the rigorous demands of two-stage heat treatments.

Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory needs. Whether you require stable 1400°C environments for ceramicization or precise gas-flow control for Chemical Vapor Deposition, our equipment delivers the reliability your research deserves.

Ready to optimize your aerogel production?

Contact Our Experts Today to discuss your custom furnace requirements!

Visual Guide

References

- Meng Lan, Qiangang Fu. Armoring Boron Nitride with Pyrolytic Carbon Layers for Tunable Rigidity and Flexibility. DOI: 10.1002/advs.202504649

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability