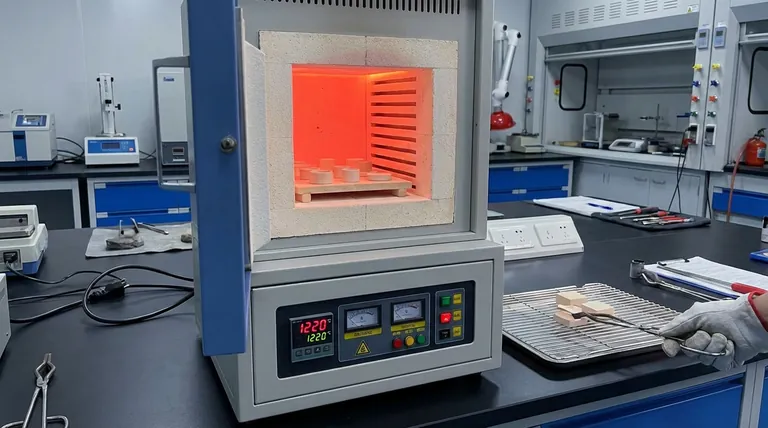

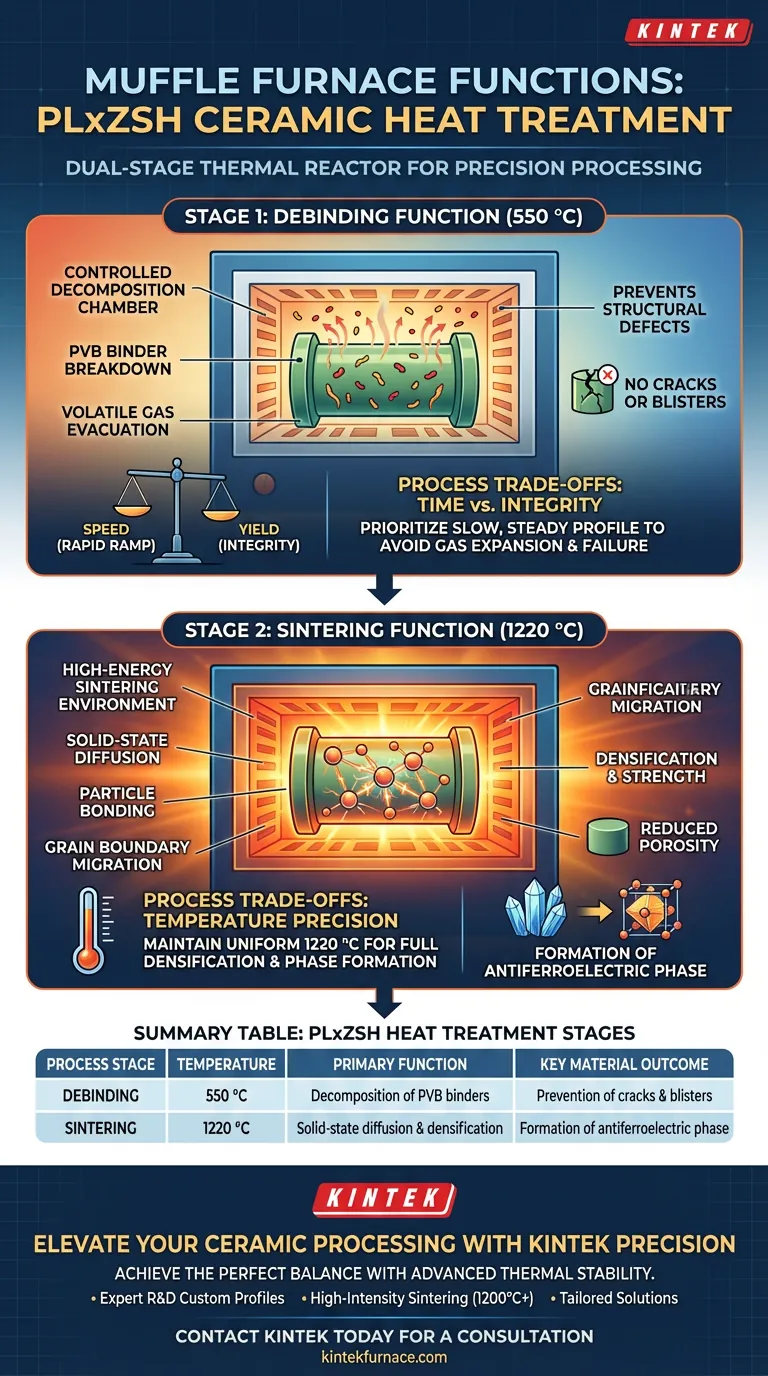

The high-temperature muffle furnace operates as a dual-stage thermal reactor in the processing of PLxZSH ceramics, executing two distinct physical processes based on specific temperature thresholds. At 550 °C, the furnace functions as a controlled decomposition chamber to gently evacuate organic binders without damaging the fragile green body. At 1220 °C, it transitions into a high-energy sintering environment, providing the thermal activation energy necessary to fuse ceramic particles and stabilize the material’s crystalline structure.

The success of PLxZSH ceramic fabrication depends on the furnace's ability to balance gentle organic removal with high-intensity densification. The equipment must first ensure structural integrity by slowly decomposing the PVB binder before applying the intense heat required to drive solid-state diffusion and establish the material's antiferroelectric properties.

Stage 1: The Debinding Function (550 °C)

Controlled Decomposition of Organic Binders

The primary function of the furnace at this stage is the thermal decomposition of polyvinyl butyral (PVB). This organic binder was originally introduced during the molding process to provide shape and cohesion to the raw ceramic powder.

At 550 °C, the furnace maintains a specific thermal environment that allows the PVB to break down into volatile gases. This temperature is carefully selected to ensure complete removal of the organic material before higher temperatures are reached.

Preventing Structural Defects

The furnace's role extends beyond simple heating; it must facilitate a slow and controlled removal rate. If the temperature rises too quickly or fluctuates, the rapid expansion of escaping gases can cause internal pressure buildup.

By maintaining precise control at 550 °C, the furnace prevents the formation of cracks and blisters in the ceramic body. This ensures the component retains its net shape and structural integrity prior to the sintering phase.

Stage 2: The Sintering Function (1220 °C)

Driving Solid-State Diffusion

Once the binder is removed, the furnace ramps up to 1220 °C to initiate solid-state diffusion. At this elevated temperature, the atoms within the ceramic powder gain enough thermal energy to move and bond with neighboring particles.

The muffle furnace provides the consistent, high-temperature soak required for these atomic movements to occur efficiently. This diffusion is the fundamental mechanism that turns loose powder into a solid object.

Grain Boundary Migration and Densification

The furnace facilitates grain boundary migration, a process where individual crystals grow and pores between particles are eliminated. This leads to the densification of the ceramic, significantly increasing its mechanical strength and reducing porosity.

Without sustaining this specific temperature, the material would remain porous and structurally weak.

Formation of the Antiferroelectric Phase

Beyond physical densification, the 1220 °C environment drives the chemical and crystallographic changes necessary to form the antiferroelectric phase. This is the critical functional property of PLxZSH ceramics.

The furnace ensures the material reaches the thermodynamic state required to stabilize this specific phase, which dictates the final electrical performance of the component.

Understanding the Process Trade-offs

Time vs. Integrity at 550 °C

There is a critical trade-off between processing speed and yield during the debinding stage. While a furnace can heat rapidly, rushing the ramp to 550 °C significantly increases the risk of catastrophic failure due to gas expansion.

Operators must prioritize a slow, steady profile over throughput speed to avoid essentially "exploding" the binder out of the ceramic matrix.

Temperature Precision at 1220 °C

At the sintering stage, the trade-off involves energy consumption versus material quality. Maintaining 1220 °C requires significant energy, but even minor deviations can prevent full densification or phase formation.

If the furnace fails to hold this temperature uniformly, the ceramic may suffer from incomplete diffusion, resulting in poor electrical properties and lower density.

Achieving Optimal Material Properties

To maximize the performance of PLxZSH ceramics, you must align the furnace's capabilities with your specific processing goals:

- If your primary focus is structural integrity: Prioritize the precision of the ramp rate up to 550 °C to ensure the PVB binder is removed without inducing micro-cracks.

- If your primary focus is electrical performance: Ensure the furnace can maintain a stable, uniform soak at 1220 °C to guarantee full densification and the correct antiferroelectric phase formation.

By strictly adhering to these thermal milestones, you transform a fragile powder compact into a robust, high-performance functional ceramic.

Summary Table:

| Process Stage | Temperature | Primary Function | Key Material Outcome |

|---|---|---|---|

| Debinding | 550 °C | Decomposition of PVB binders | Prevention of cracks and blisters |

| Sintering | 1220 °C | Solid-state diffusion & densification | Formation of antiferroelectric phase |

Elevate Your Ceramic Processing with KINTEK Precision

Achieving the perfect balance between 550 °C debinding and 1220 °C sintering requires world-class thermal stability. KINTEK provides advanced high-temperature solutions—including Muffle, Tube, Rotary, and Vacuum systems—engineered to deliver the precise ramp rates and uniform heat distribution essential for PLxZSH ceramic performance.

Why choose KINTEK?

- Expert R&D: Custom thermal profiles to prevent structural defects during organic removal.

- High-Intensity Sintering: Reliable 1200°C+ environments for maximum material densification.

- Tailored Solutions: Fully customizable furnaces designed for your unique laboratory or production needs.

Ready to optimize your material properties? Contact KINTEK today for a consultation and let our technical team help you achieve superior heat treatment results.

Visual Guide

References

- Yongxiao Zhou, Jun Chen. Design of antiferroelectric polarization configuration for ultrahigh capacitive energy storage via increasing entropy. DOI: 10.1038/s41467-025-56194-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination