At their core, retort furnaces are used for high-temperature material processing where controlling the atmospheric environment is just as critical as controlling the temperature. Their primary applications revolve around heat treating metals, ceramics, and powders in a sealed chamber, or "retort," to prevent oxidation and enable specific chemical reactions. This makes them indispensable for processes like annealing, sintering, and brazing that demand high material purity and specific surface finishes.

The defining feature of a retort furnace is not just its ability to get hot, but its ability to create a sealed, controlled environment. This separation from the ambient air is what allows for the advanced material processing that standard furnaces cannot achieve.

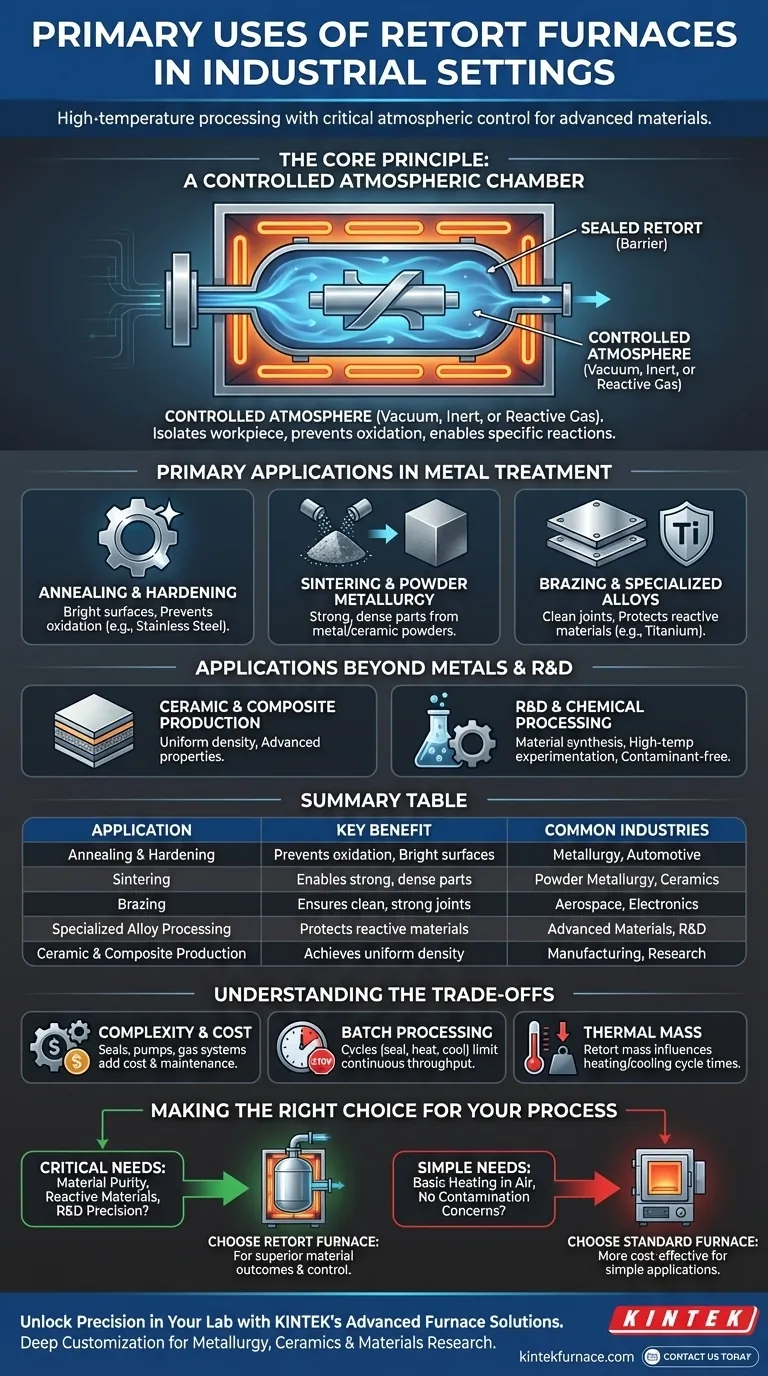

The Core Principle: A Controlled Atmospheric Chamber

The key to understanding a retort furnace is the retort itself. This is a sealed vessel, typically made of high-temperature alloy or ceramic, that sits inside the main furnace heating chamber.

What the Retort Achieves

The retort acts as a barrier, isolating the workpiece from the furnace's heating elements and the outside air. This isolation is the furnace's primary advantage.

It allows operators to precisely manage the atmosphere surrounding the material. This can mean creating a vacuum to remove all reactive gases or introducing a specific inert gas (like argon or nitrogen) or even a reactive gas to facilitate a chemical process.

Primary Applications in Metal Treatment

The most common use for retort furnaces is in metallurgy, where surface quality and material purity are paramount.

Annealing and Hardening

Retort furnaces are ideal for bright annealing of materials like stainless steel. By processing the parts in an inert atmosphere, the furnace prevents oxidation, resulting in a clean, "bright" surface that requires no post-process cleaning. The same principle applies to hardening, where precise atmospheric control ensures consistent metallurgical properties.

Sintering and Powder Metallurgy

Sintering is the process of heating powdered materials below their melting point until their particles bond together. A retort furnace provides the clean, oxygen-free environment necessary to produce strong, dense parts from metal or ceramic powders without introducing impurities.

Brazing

Furnace brazing joins metal components using a filler metal with a lower melting point. A controlled atmosphere is essential to ensure the filler metal flows cleanly and creates a strong, void-free joint. An inert or reactive atmosphere prevents oxidation of the base metals during the high-temperature cycle.

Specialized Alloy Processing

Materials that are highly reactive with oxygen, such as titanium, must be heat-treated in a vacuum or a pure inert gas. A retort furnace is one of the only ways to achieve the atmospheric purity required to process these advanced alloys without compromising their structural integrity.

Applications Beyond Metals

The versatility of atmospheric control extends the use of retort furnaces to many other advanced materials and processes.

Ceramic and Composite Production

Just as with powdered metals, ceramic sintering benefits greatly from the uniform heating and controlled environment of a retort furnace. This ensures the final ceramic part achieves its desired density and mechanical properties. It is also used in creating advanced composite materials.

Chemical and Material Processing

Retort furnaces can be used as high-temperature chemical reactors. Applications include powder roasting to induce chemical changes in a material and even flue gas treatment, where the controlled environment is used to process emissions.

The Role in Research and Development

Retort furnaces are a staple in universities, scientific institutes, and industrial laboratories for their precision and repeatability.

High-Temperature Experimentation

When developing new materials or studying chemical reactions at high temperatures, a retort furnace provides a reliable and contaminant-free environment. This makes it indispensable for material synthesis, high-temperature atmosphere sintering, and fundamental material property testing.

Understanding the Trade-offs

While powerful, a retort furnace is not always the necessary choice. Understanding its limitations is key.

Complexity and Cost

The retort itself, along with the required seals, vacuum pumps, and gas management systems, adds significant complexity and cost compared to a standard air furnace. Maintenance of these components is also a critical consideration.

Batch Processing and Throughput

By their nature, most retort furnace designs are geared towards batch processing. Sealing the retort, pulling a vacuum, running the cycle, and cooling before unsealing can limit overall throughput compared to continuous belt furnaces used for high-volume production.

Thermal Mass

The retort chamber has its own thermal mass that must be heated and cooled along with the payload. While modern designs are highly efficient, this can sometimes influence cycle times compared to processes where materials are heated directly.

Making the Right Choice for Your Process

Use this guide to determine if a retort furnace aligns with your technical requirements.

- If your primary focus is material purity and surface finish: For processes like bright annealing or brazing where preventing any oxidation is critical, a retort furnace is essential.

- If you are working with reactive or advanced materials: For processing titanium, refractory metals, or materials in powder form, the atmospheric control of a retort furnace is non-negotiable.

- If you require a repeatable environment for R&D: For scientific experiments or material development, the precision and control offered by a retort furnace are unmatched.

- If your process is simple heating in air: For basic applications like tempering or drying where atmospheric contamination is not a concern, a simpler and more cost-effective standard furnace is the better tool.

Ultimately, selecting a retort furnace is a decision to prioritize precise atmospheric control to achieve superior material outcomes.

Summary Table:

| Application | Key Benefit | Common Industries |

|---|---|---|

| Annealing & Hardening | Prevents oxidation for bright surfaces | Metallurgy, Automotive |

| Sintering | Enables strong, dense parts from powders | Powder Metallurgy, Ceramics |

| Brazing | Ensures clean, strong joints in metals | Aerospace, Electronics |

| Specialized Alloy Processing | Protects reactive materials like titanium | Advanced Materials, R&D |

| Ceramic & Composite Production | Achieves uniform density and properties | Manufacturing, Research |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in metallurgy, ceramics, or materials research, our retort furnaces deliver the atmospheric control you need for superior results.

Contact us today to discuss how our tailored solutions can enhance your processes and drive innovation!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments