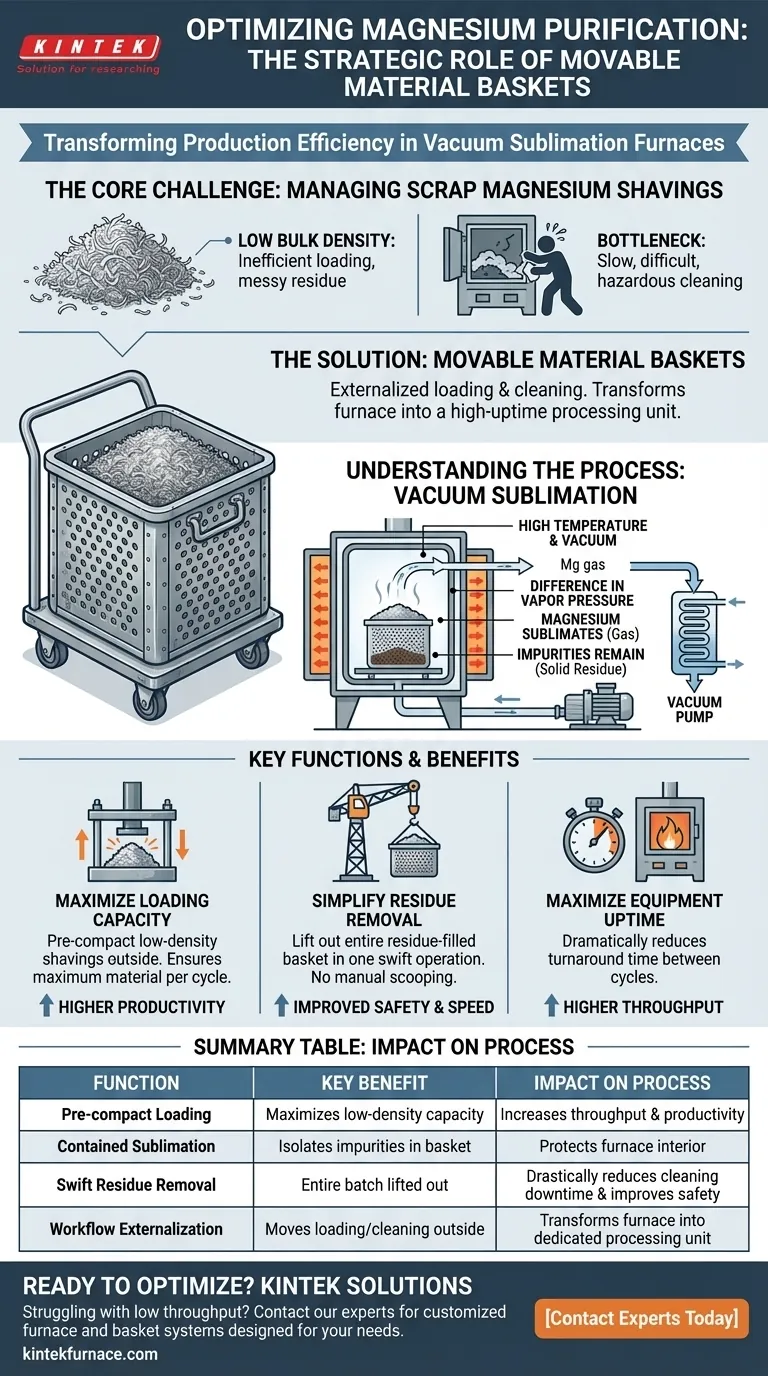

The primary reasons for using movable material baskets in this process are to maximize the loading capacity of low-density magnesium shavings and to drastically simplify the removal of impurity residue after sublimation is complete. These two functions directly address major operational bottlenecks, leading to significantly improved production efficiency.

The core challenge in processing scrap magnesium shavings is managing the material's physical form—both its initial low density and the messy residue it leaves behind. Movable baskets solve this by externalizing the loading and cleaning processes, which transforms the furnace from a multi-step station into a dedicated, high-uptime processing unit.

Understanding the Process: Vacuum Sublimation

The Principle of Purification

A vacuum sublimation furnace purifies magnesium by leveraging a fundamental physical principle: differences in vapor pressure.

The furnace creates a high-temperature, high-vacuum environment. Under these conditions, magnesium has a much higher vapor pressure than impurities like aluminum, iron, or silicon.

This causes the magnesium to turn directly into a gas (sublimate), leaving the less volatile impurities behind as a solid residue. The pure magnesium vapor is then collected and condensed in a cooler part of the furnace.

The Strategic Role of Movable Baskets

Movable baskets are not just containers; they are a critical component of an efficient workflow designed to maximize the productivity of the furnace.

Solving the Loading Challenge

Scrap magnesium shavings have a very low bulk density, meaning they take up a lot of space for their weight. Loading them loosely into a furnace would result in an inefficient batch size.

Movable baskets allow operators to compact the shavings outside the furnace. This pre-processing step ensures that the maximum possible amount of material is loaded for each cycle, making every run more productive.

Streamlining Residue Removal

After the pure magnesium has vaporized, a mixture of solid impurities, often called slag or residue, remains. Cleaning this material from the inside of a hot furnace chamber is a slow, difficult, and often hazardous task.

By containing the entire batch within a basket, the entire residue-filled container can be lifted out in a single, swift operation. This completely eliminates the need for manual scooping or scraping inside the furnace.

Maximizing Equipment Uptime

The combined effect of efficient loading and rapid unloading is a dramatic reduction in the furnace's "turnaround time"—the period between the end of one cycle and the beginning of the next.

By minimizing downtime for cleaning and loading, the furnace can spend more of its time actively processing material. This directly translates to higher throughput and overall production efficiency.

Common Pitfalls and Considerations

While highly effective, implementing a basket-based system requires forethought to avoid potential issues and ensure a smooth operation.

Basket Material and Durability

The baskets must be constructed from materials that can withstand the extreme heat and vacuum conditions without degrading, deforming, or contaminating the pure magnesium. Choosing an inappropriate alloy for the basket can lead to premature failure and costly downtime.

Handling and Infrastructure

These baskets are heavy, especially when loaded with material. The facility must be equipped with the necessary overhead cranes or other lifting mechanisms to move them safely and efficiently. The workflow and floor plan must be designed to accommodate this movement.

Thermal Management

Introducing a large, relatively cool basket into a hot furnace and removing a hot one requires careful management of thermal cycles. This can impact the furnace's energy consumption and the lifespan of its internal components.

Making the Right Choice for Your Goal

Adopting movable baskets is a strategic decision aimed at optimizing the entire purification workflow.

- If your primary focus is maximizing throughput: A movable basket system is essential, as it directly minimizes the two most time-consuming non-processing steps: loading and cleaning.

- If your primary focus is operational efficiency and safety: Containing residue within a basket simplifies handling, reduces operator exposure to the hot furnace interior, and creates a cleaner, more controlled work environment.

Ultimately, this simple tooling innovation allows you to treat the furnace as a pure processing engine, not a station for manual material handling.

Summary Table:

| Function | Key Benefit | Impact on Process |

|---|---|---|

| Pre-compact Loading | Maximizes low-density shaving capacity per batch | Increases furnace throughput and productivity |

| Contained Sublimation | Isolates impurities within the basket | Protects furnace interior from contamination |

| Swift Residue Removal | Enables entire batch to be lifted out post-cycle | Drastically reduces cleaning downtime and improves safety |

| Workflow Externalization | Moves loading/cleaning outside the furnace | Transforms furnace into a dedicated processing unit |

Ready to Optimize Your Magnesium Purification Process?

Struggling with low throughput and difficult residue cleaning in your vacuum sublimation operations? The strategic use of movable material baskets can transform your efficiency and safety.

Backed by expert R&D and manufacturing, KINTEK offers high-temperature vacuum furnaces and custom basket solutions designed for unique material processing needs like yours. Our systems are engineered to maximize your productivity.

Contact our experts today to discuss how a customized furnace and basket system can solve your specific operational challenges and boost your production efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today