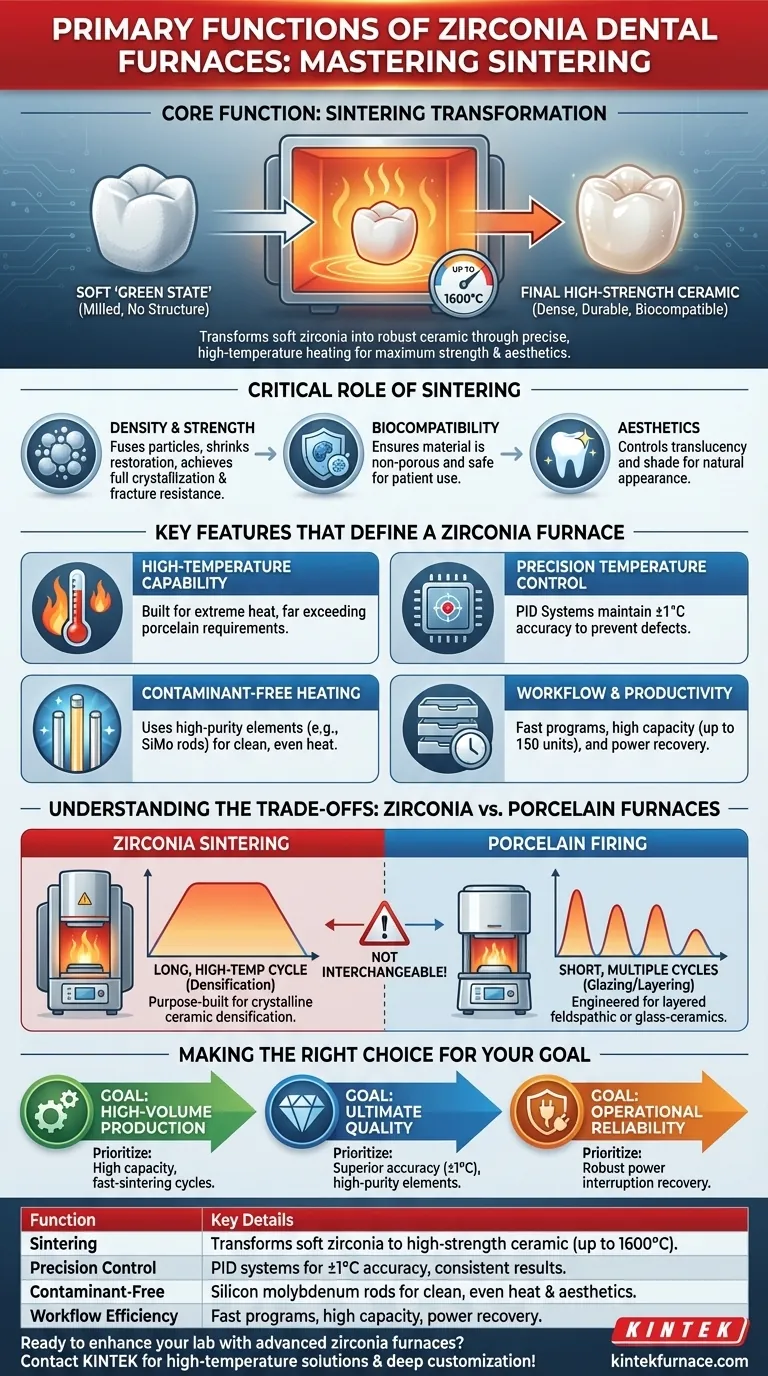

At its core, a zirconia dental furnace performs one critical function: sintering. It transforms a soft, milled zirconia restoration into a final, high-strength ceramic through a precisely controlled, high-temperature heating process. This is essential for creating durable and biocompatible crowns, bridges, and implant abutments that can withstand the forces of mastication.

A zirconia furnace is not merely an oven; it is a specialized instrument engineered to unlock the specific mechanical and aesthetic properties of zirconia. Its primary role is to ensure that a dental restoration achieves its maximum potential for strength, longevity, and patient safety.

The Critical Role of Sintering

Sintering is the process that gives a zirconia restoration its final, robust characteristics. The furnace manages this transformation with extreme precision.

From a Soft State to a Hard Ceramic

When a dental lab mills a zirconia restoration, the material is in a soft, chalk-like, pre-sintered state. This "green state" is easy to mill but has no structural integrity. The sintering process heats these milled units, causing the zirconia particles to fuse and densify, dramatically shrinking the restoration and converting it into a hard, tough ceramic.

Achieving Maximum Strength and Durability

The key function of a zirconia furnace is its ability to reach and maintain very high temperatures, often up to 1600°C. This intense, prolonged heat is required to achieve the full crystallization and density that gives zirconia its exceptional strength and fracture resistance.

Ensuring Biocompatibility and Aesthetics

Proper sintering is also crucial for the material's biocompatibility. An incomplete cycle can leave the material porous and weak. Furthermore, the heating and cooling protocols directly influence the final translucency and shade of the restoration, ensuring it meets aesthetic requirements.

Key Features that Define a Zirconia Furnace

While other furnaces exist in a dental lab, specific features make a zirconia furnace uniquely suited for its task.

High-Temperature Capability

This is the single most important technical function. Unlike porcelain firing furnaces, zirconia furnaces are built to handle the extreme temperatures needed for sintering, which far exceed the requirements for other dental ceramics.

Precision Temperature Control

Leading furnaces use advanced PID (Proportional-Integral-Derivative) control systems to maintain temperature accuracy within ±1℃. This precision prevents thermal shock, micro-fractures, and inconsistent results, ensuring every restoration meets the exact specifications.

Contaminant-Free Heating Elements

To prevent discoloration of the white zirconia, these furnaces use high-purity heating elements, such as silicon molybdenum rods. These are designed to provide clean, even heat distribution without releasing contaminants that could compromise the final aesthetic.

Workflow and Productivity Enhancements

Modern furnaces are designed for efficiency. Features like fast sintering programs (some under 65 minutes), the ability to stack multiple crucibles to process up to 150 units at once, and power interruption recovery are critical functions for a high-production lab environment.

Understanding the Trade-offs: Zirconia vs. Other Furnaces

A common point of confusion is how a zirconia furnace differs from a standard ceramic or porcelain furnace. They are not interchangeable.

Purpose-Built for Different Materials

A zirconia furnace is a sintering furnace. A porcelain furnace is a firing furnace. The former is designed for the densification of a crystalline ceramic (zirconia), while the latter is engineered for glazing and firing layered feldspathic or glass-ceramics.

Vastly Different Thermal Programs

Zirconia sintering involves a long ramp-up, a prolonged hold at a very high peak temperature, and a controlled cool-down. Porcelain firing involves multiple, often shorter cycles at lower temperatures to build up layers of color and translucency. Using the wrong furnace will destroy the restoration.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on the specific goals of your dental practice or laboratory.

- If your primary focus is high-volume zirconia production: Prioritize models with high capacity (stackable trays) and proven fast-sintering cycles to maximize throughput.

- If your primary focus is ultimate restoration quality: Look for superior temperature accuracy (±1°C), programmable cycles, and high-purity heating elements to ensure consistency.

- If your primary focus is operational reliability: Ensure the furnace has a robust power interruption recovery memory to safeguard restorations during long sintering programs.

Ultimately, investing in the right zirconia furnace is a foundational step in delivering strong, reliable, and aesthetic digital dental restorations.

Summary Table:

| Function | Key Details |

|---|---|

| Sintering | Transforms soft, milled zirconia into high-strength ceramic through high-temperature heating (up to 1600°C). |

| Precision Control | Uses PID systems for ±1°C accuracy to ensure consistent results and prevent defects. |

| Contaminant-Free Heating | Employs silicon molybdenum rods for clean, even heat distribution to maintain aesthetics. |

| Workflow Efficiency | Features fast sintering programs, high capacity (up to 150 units), and power interruption recovery for productivity. |

Ready to enhance your dental lab's capabilities with advanced zirconia furnaces? KINTEK specializes in high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique needs for sintering zirconia crowns, bridges, and more. Contact us today to discuss how our furnaces can boost your efficiency and restoration quality!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision