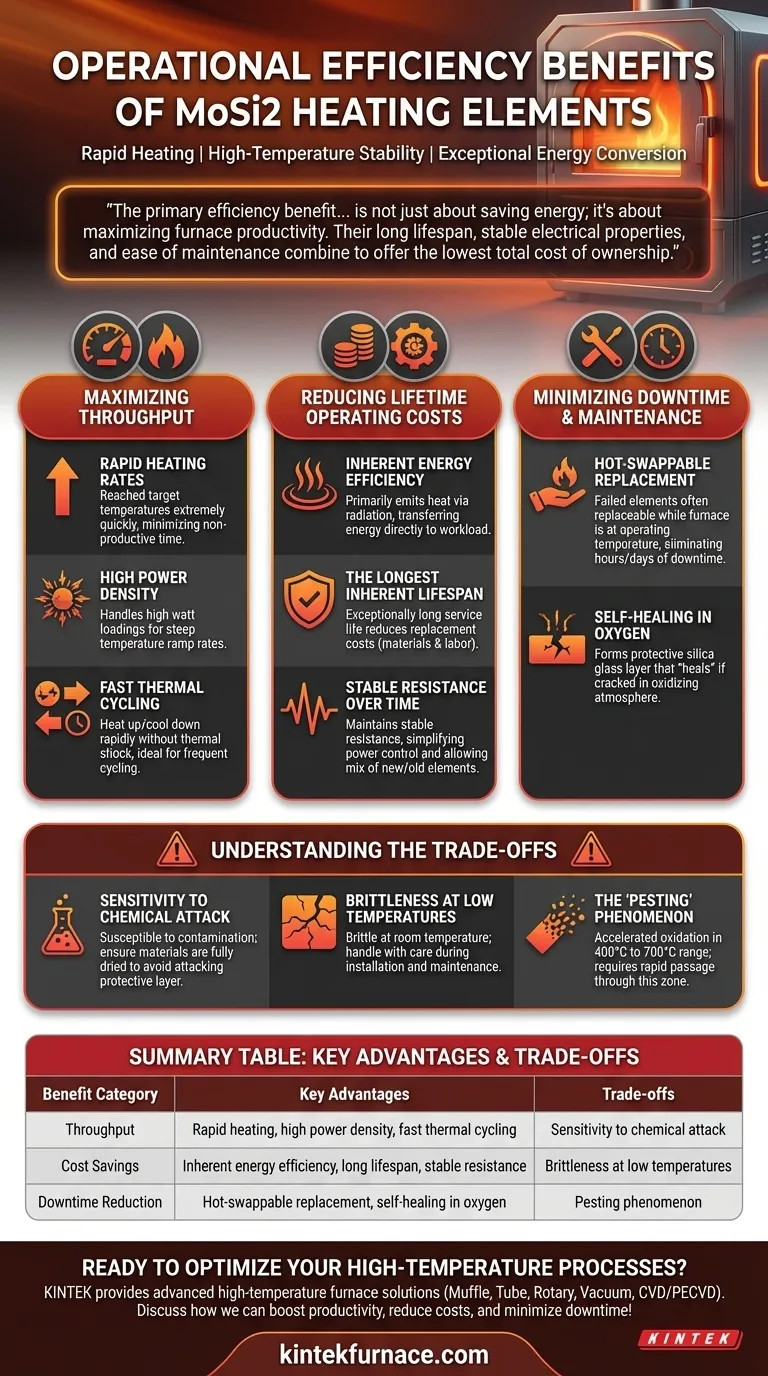

At their core, MoSi2 (Molybdenum Disilicide) heating elements deliver operational efficiency through a combination of rapid heating rates, high-temperature stability, and exceptional energy conversion. This unique profile directly translates to lower energy bills, increased production throughput, and significantly reduced furnace downtime.

The primary efficiency benefit of MoSi2 is not just about saving energy; it's about maximizing furnace productivity. Their long lifespan, stable electrical properties, and ease of maintenance combine to offer the lowest total cost of ownership for many high-temperature processes.

Maximizing Throughput with Rapid Heating

One of the most significant operational advantages of MoSi2 elements is their ability to reach target temperatures extremely quickly. This minimizes the non-productive time your furnace spends heating up.

High Power Density and Watt Loading

MoSi2 elements can handle very high watt loadings. This means they can convert a large amount of electrical energy into heat in a small area, enabling steep temperature ramp rates that are impossible with many other element types.

Fast Thermal Cycling

These elements can be heated up and cooled down rapidly and repeatedly without suffering from thermal shock or degradation. This makes them ideal for processes that do not run continuously and require frequent cycling.

Reducing Lifetime Operating Costs

The initial investment in MoSi2 elements is often paid back through lower ongoing operational expenses over the life of the furnace.

Inherent Energy Efficiency

MoSi2 elements primarily emit heat via radiation. This is a highly efficient method for transferring energy directly to the workload, minimizing wasted energy heating the air or furnace chamber.

The Longest Inherent Lifespan

When operated correctly, MoSi2 elements have an exceptionally long service life. This durability directly reduces the costs associated with frequent element replacement, both in terms of materials and labor.

Stable Resistance Over Time

Unlike Silicon Carbide (SiC) elements, which increase in resistance as they age, MoSi2 elements maintain a stable resistance throughout their life. This allows you to connect new and old elements in the same circuit without issue and simplifies power control system requirements.

Minimizing Downtime and Maintenance

Ease of service and robustness are key drivers of the operational efficiency provided by MoSi2 elements.

Hot-Swappable Element Replacement

A failed element can often be replaced while the furnace is still at operating temperature. This is a critical advantage in production environments, as it can eliminate hours or even days of downtime associated with cooling, replacing, and reheating the furnace.

Self-Healing in Oxygen

In an oxidizing atmosphere, MoSi2 elements form a thin, protective layer of silica glass (SiO2) on their surface. If this layer is cracked, the underlying material re-oxidizes, effectively "healing" the element and ensuring its continued long life.

Understanding the Trade-offs

To fully realize their benefits, you must be aware of their specific operational requirements and limitations. Objectivity requires acknowledging these factors.

Sensitivity to Chemical Attack

MoSi2 elements are susceptible to contamination. Care must be taken to ensure materials processed in the furnace, such as certain paints or colorants on zirconia, are fully dried and do not release vapors that can attack the elements' protective layer.

Brittleness at Low Temperatures

At room temperature, MoSi2 elements are brittle and must be handled with care during installation and maintenance to avoid fracture. They gain ductility as they heat up.

The "Pesting" Phenomenon

In a specific low-temperature range (approximately 400°C to 700°C), MoSi2 elements can be subject to accelerated oxidation, or "pesting," which can cause them to disintegrate. Furnaces using these elements must be designed to move through this temperature zone quickly.

Making the Right Choice for Your Application

Selecting the right heating element technology depends entirely on your operational priorities.

- If your primary focus is maximizing production speed and throughput: The rapid heating and thermal cycling capabilities are your most significant advantages.

- If your primary focus is reducing long-term operational costs: The combination of long lifespan, stable resistance, and energy efficiency will yield the lowest total cost of ownership in demanding high-temperature applications.

- If your primary focus is operational simplicity and uptime: The ability to replace elements while the furnace is hot and the stability of the elements over time dramatically reduce maintenance complexity and process downtime.

By understanding both their powerful benefits and their specific operational requirements, you can effectively leverage MoSi2 elements to achieve superior performance and efficiency in your high-temperature processes.

Summary Table:

| Benefit Category | Key Advantages |

|---|---|

| Throughput | Rapid heating rates, high power density, fast thermal cycling |

| Cost Savings | Inherent energy efficiency, long lifespan, stable resistance |

| Downtime Reduction | Hot-swappable replacement, self-healing in oxygen |

| Trade-offs | Sensitivity to chemical attack, brittleness at low temperatures, pesting phenomenon |

Ready to optimize your high-temperature processes with MoSi2 heating elements? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our solutions can boost your productivity, reduce costs, and minimize downtime!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance